Method for rubber vulcanization of semisteel tire

A rubber vulcanization and tire technology, applied in the field of tire production, can solve the problems of low efficiency of superheated vulcanization, unstable tire quality and high energy consumption, and achieve the effect of stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

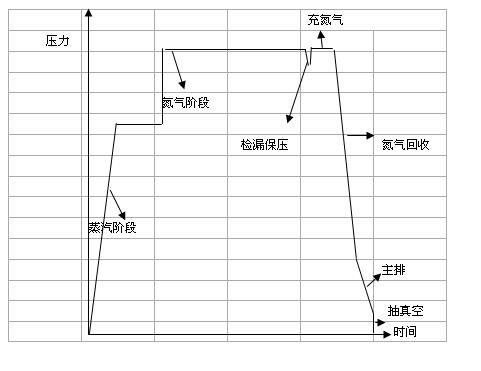

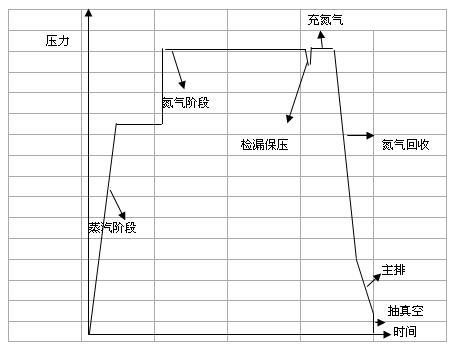

[0010] The present invention comprises the following steps, a. Filling with saturated steam for 1.5 minutes, filling the vulcanization bladder with saturated steam with a temperature of 206°C to 214°C and a pressure of 1.7Mpa to 1.9Mpa, such as the process conditions of steam within 1.5 minutes When the temperature and pressure do not reach the standard value, the computer will automatically delay the vulcanization in the nitrogen filling stage of step e; b. Inflate saturated steam according to the specifications of the tire, and keep the temperature in the vulcanizing bladder at 206°C to 214°C and the pressure to maintain At 1.7Mpa~1.9Mpa, the steam filling time is calculated according to the tire temperature data measured by the thermocouple, using the Arrhenius equation to calculate a reasonable time to achieve the purpose of energy saving; c. Then switch the steam and fill according to the tire specifications Inflate nitrogen, the temperature of nitrogen is 15℃~35℃, the pur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com