Trolley track of ladle crane and mounting method of trolley track

A trolley track and installation method technology, which is applied in the direction of track system, transportation and packaging, load hanging components, etc., can solve problems affecting normal use, affecting the service life of trolley wheels, axles and electrical equipment, and safety accidents. The frequency of maintenance, the good operating environment of the trolley, and the effect of reducing the cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

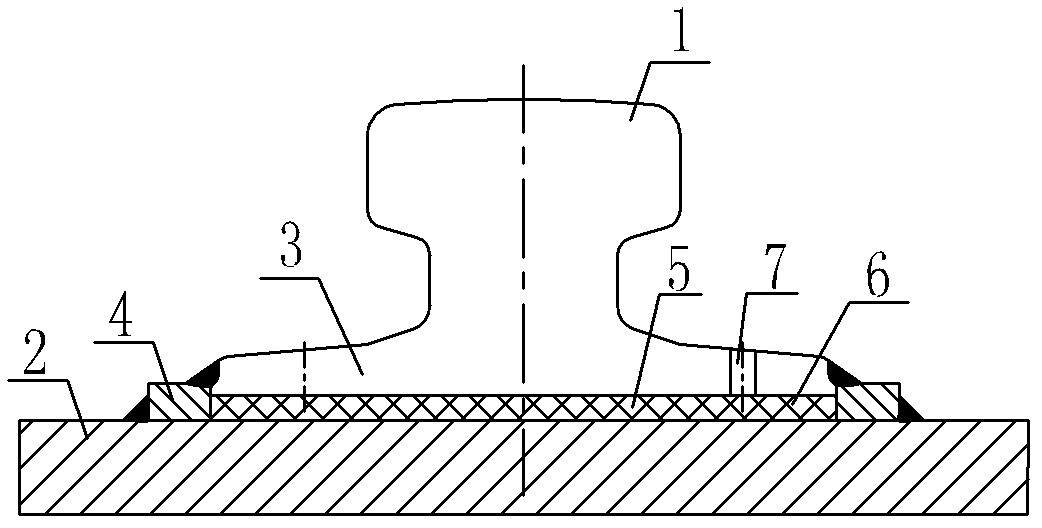

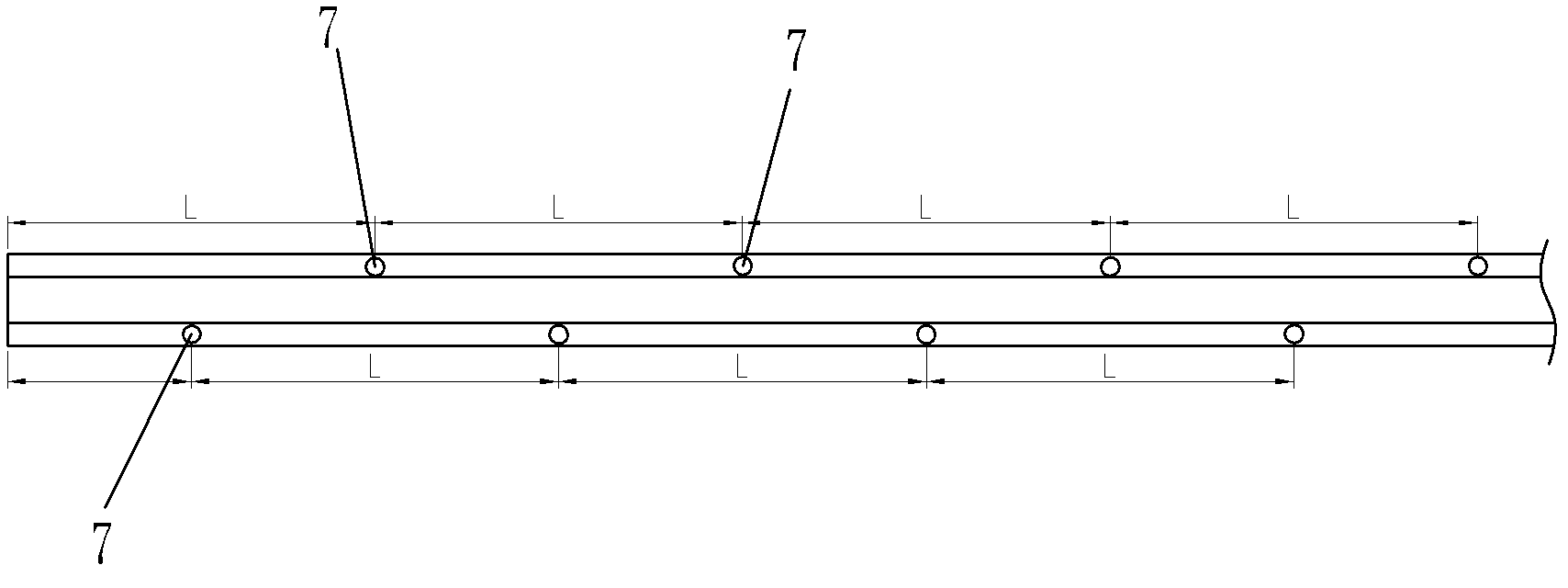

[0027] Such as figure 1 The casting crane trolley track shown in , includes a steel rail 1, which is laid on the rail bearing plate 2, and a stopper 4 is welded on both sides of the lower part of the rail 3, and the stopper 4 is welded on the rail bearing plate 2 at the same time. Wherein a space 5 is formed among the block 4, the rail 1 and the rail bearing plate 2, and an adhesive 6 is injected into the space 5 so that the rail 1 and the rail bearing plate 2 are bonded and fixed together. The lower part of the rail 3 is provided with a through hole 7 along the direction perpendicular to the axis of the rail, and the through hole 7 communicates with the space 5

[0028] When the track is connected by multiple sections of rails 1, the adjacent rails 1 are fixed together by welding. The purpose is to eliminate the gap between the join...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com