Width flow uniformity online measuring device of water spraying device

A technology of measuring device and water spraying device, which is applied in the direction of measuring device, measuring flow/mass flow, liquid/fluid solid measurement, etc. It can solve the problems of large flow uniformity error, complexity, and influence on measurement accuracy, and achieve high efficiency, continuous and uniform Effect of Quenching Cooling System Optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

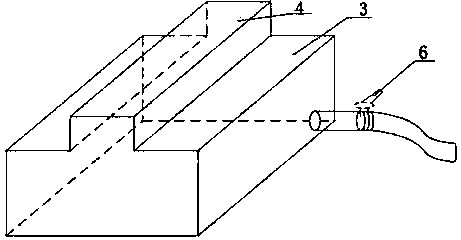

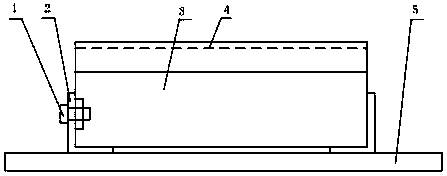

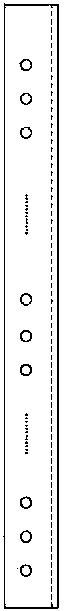

[0021] see figure 1 and figure 2 , the sprinkler device of the present invention wide direction flow uniformity on-line measuring device comprises: collecting tank body 3, is provided with opening along the length direction of collecting tank body 3, is provided with the collecting tank cover 4 that can open and close on opening, in The bottom of the water collecting tank body 3 is provided with an outlet pipe, and a valve 6 is arranged on the outlet pipe; a card slot 2 is fixed on the base 5, and the card slot 2 is provided with a plurality of circular holes, and the water collecting tank body is fixed in the circular holes by bolts. Multiple circular holes arranged equidistantly (see image 3 ). Preferably, the width of the opening on the water collecting tank body 3 is 200-300mm. Preferably, the total height of the water collection tank body 3 and the water collection tank cover 4 is less than 600mm. The card slot 2 is welded on the base 5 .

[0022] The invention is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com