Semi-transmitting half-reflection liquid crystal display and manufacturing method thereof

A transflective, liquid crystal display technology, applied in the directions of instruments, nonlinear optics, optics, etc., can solve the problems of low feasibility, high technical difficulty, increasing the difficulty of the production process of transflective liquid crystal displays, etc. Difficulty and cost of production process, simple production process, and the effect of eliminating optical delay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

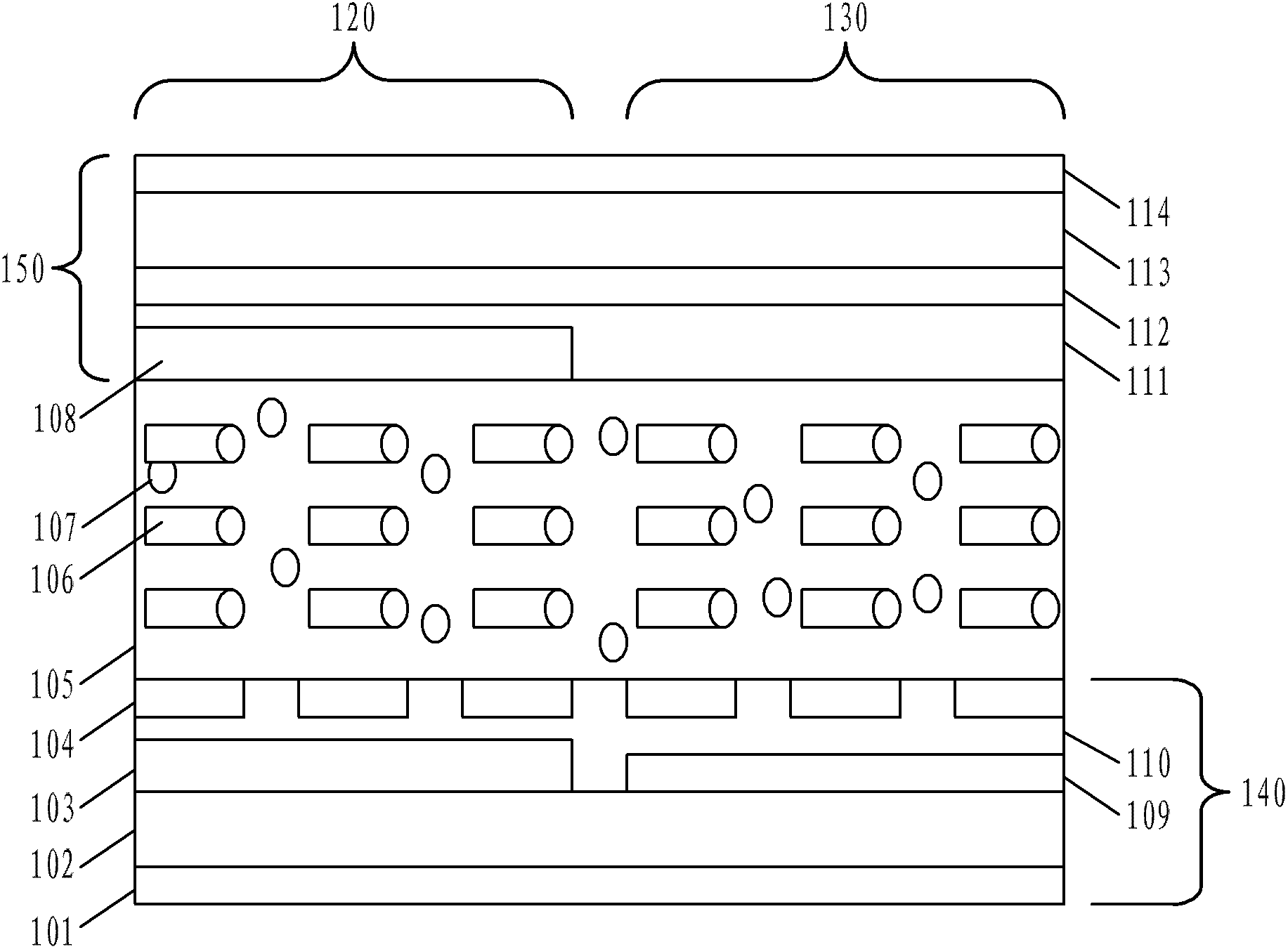

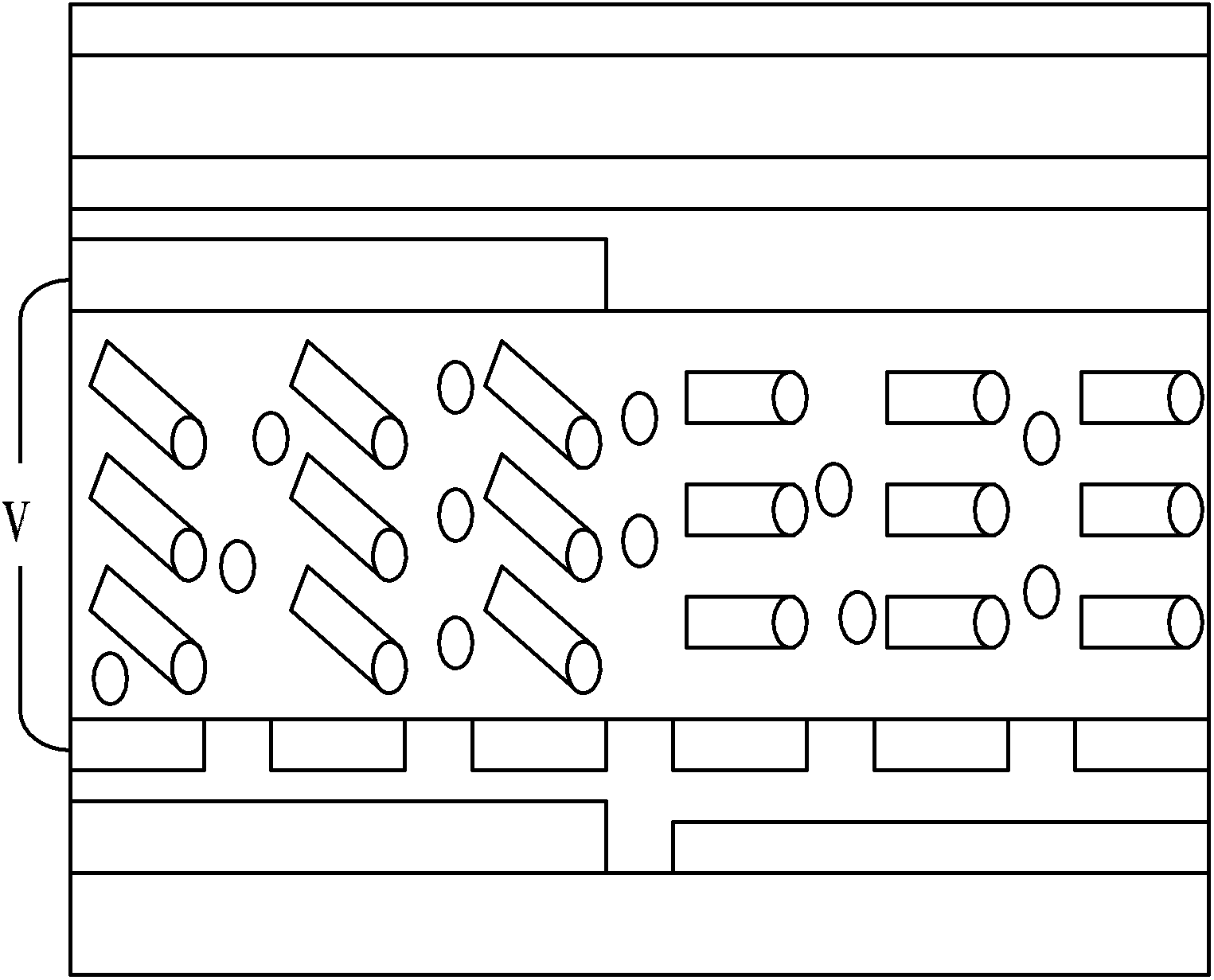

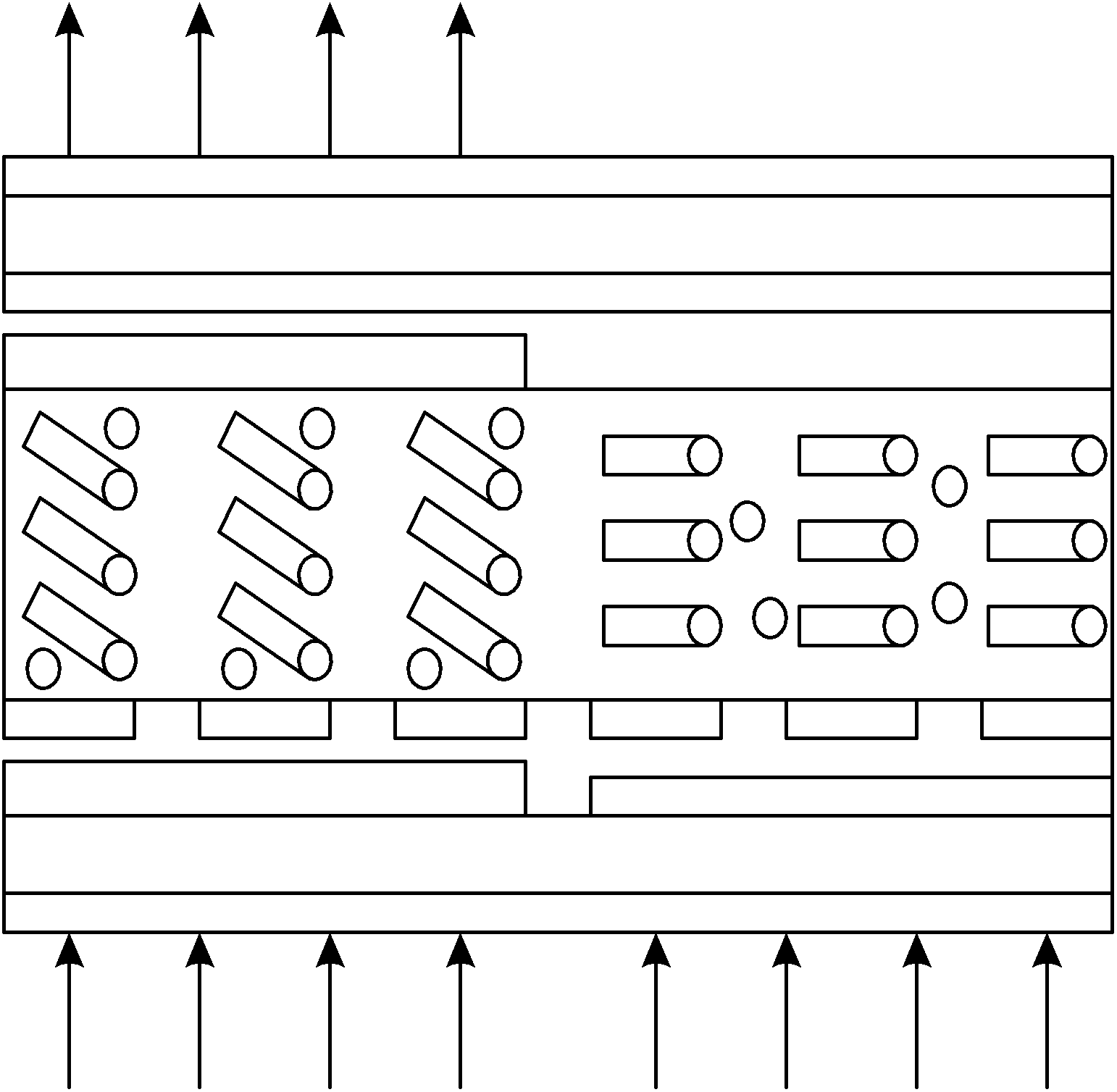

[0037] An embodiment of the present invention provides a transflective liquid crystal display, and the transflective liquid crystal display may specifically include a plurality of pixels, as shown in the attached figure 1 As shown, each pixel can be divided into two parts, the adjacent transmissive area 120 and the reflective area 130, and each pixel can specifically include:

[0038] Polarizer 101;

[0039] The substrate 102 may be referred to as an array substrate;

[0040] A transparent electrode 103 located in the transmissive area, the transparent electrode 103 can specifically be a common electrode or a pixel electrode;

[0041] Transparent electrode 104, the transparent electrode 104 can be a pixel electrode or a common electrode, specifically can be composed of a plurality of strip-shaped transparent electrode blocks, and a preset distance is spaced between the plurality of strip-shaped transparent electrode blocks, and the preset distance can be based on The charact...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com