High-rigidity cutting and feeding conveyor system for sugarcane

A conveying system, high rigidity technology, applied in harvesters, agricultural machinery and implements, applications, etc., can solve the problems of easy blockage, complex cutting and feeding devices, high breakage rate, convenient adjustment, good cutting quality, The effect of reducing head breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

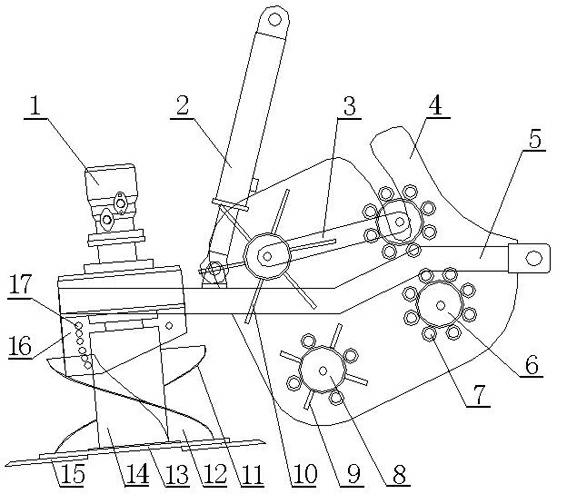

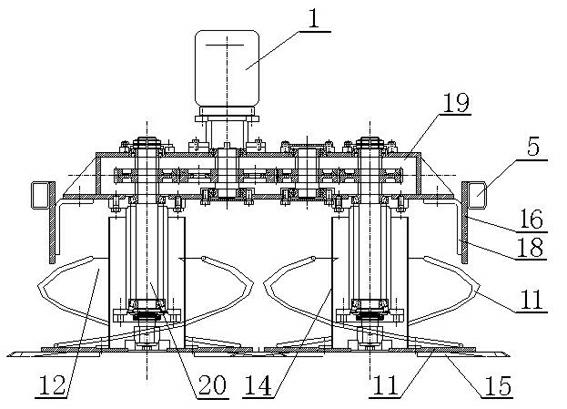

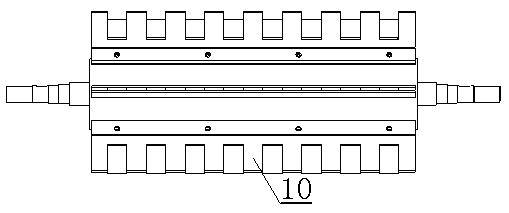

Embodiment 1

[0026] As shown in the attached figure, the high-rigidity sugarcane cutting and feeding conveying system includes cutter, feeding conveying roller assembly and lifting mechanism, and the lifting mechanism includes lifting cylinder (2) and lifting frame (5), cutter and lifting frame The front end of (5) is provided with side plate III (18) and side plate II (16), and the feeding conveying roller assembly is provided with side plate I (4); side plate III (18) and side plate II (16) It is connected by bolts; there are seven installation holes on the side plate II (14), and the installation inclination angle of the cutter head can be adjusted through the combination of different installation holes. The feeding and conveying roller assembly is fixedly connected to the lifting frame through the side plate I (4); there are hinges at the front and back of the lifting frame (5), and the front hinge is connected with the lifting cylinder (2), and the lifting cylinder (2) is a hydraulic c...

Embodiment 2

[0028] As shown in the attached figure, the high-rigidity sugarcane cutting and feeding conveying system includes cutter, feeding conveying roller assembly and lifting mechanism, and the lifting mechanism includes lifting cylinder (2) and lifting frame (5), cutter and lifting frame The front end of (5) is provided with side plate III (18) and side plate II (16), and the feeding conveying roller assembly is provided with side plate I (4); side plate III (18) and side plate II (16) It is connected by bolts; there are five installation holes on the side plate II (14), and the installation inclination angle of the cutter head can be adjusted through the combination of different installation holes. The feeding and conveying roller assembly is fixedly connected to the lifting frame through the side plate I (4); there are hinges at the front and back of the lifting frame (5), and the front hinge is connected with the lifting cylinder (2), and the lifting cylinder (2) is a hydraulic cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com