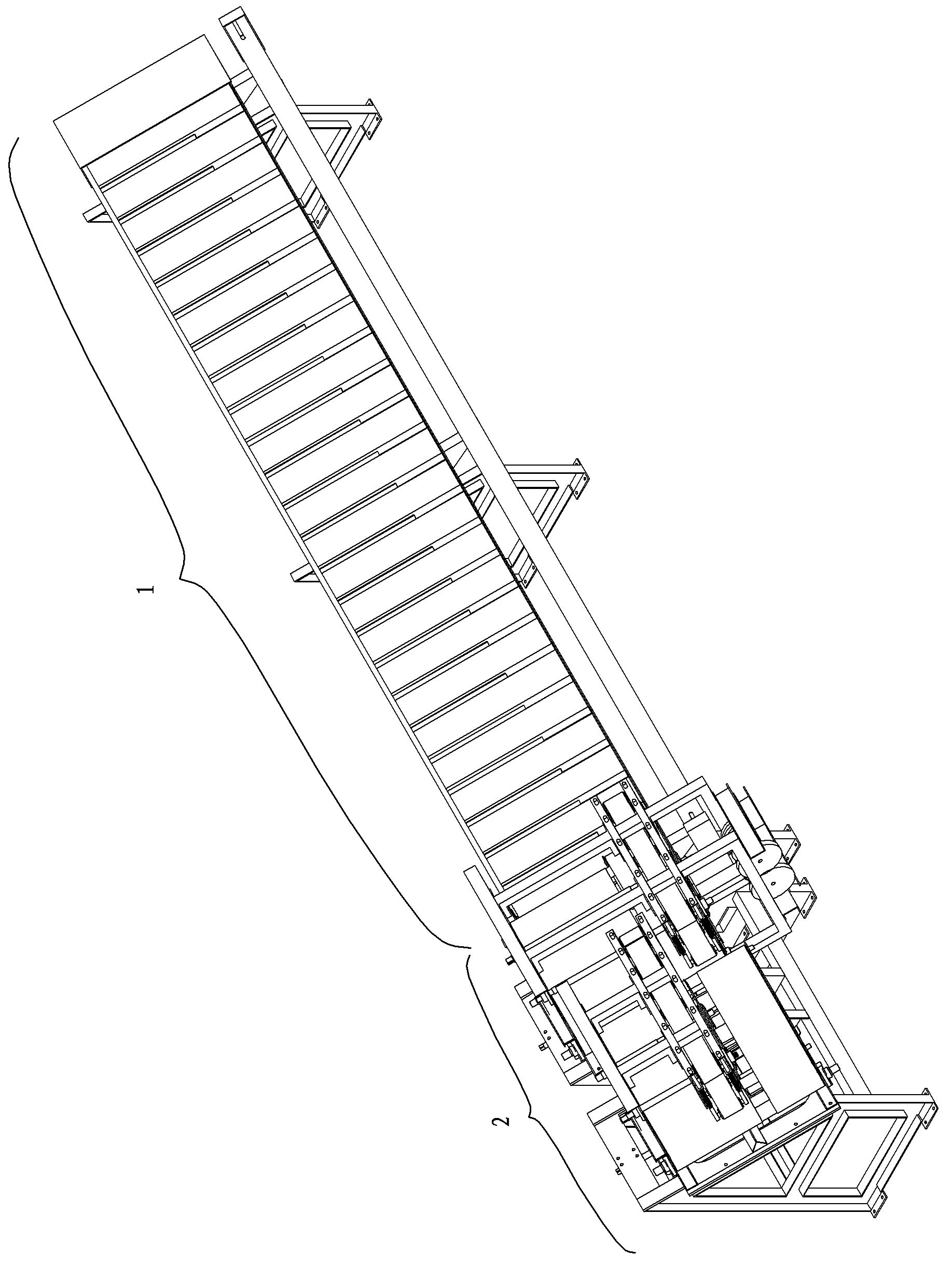

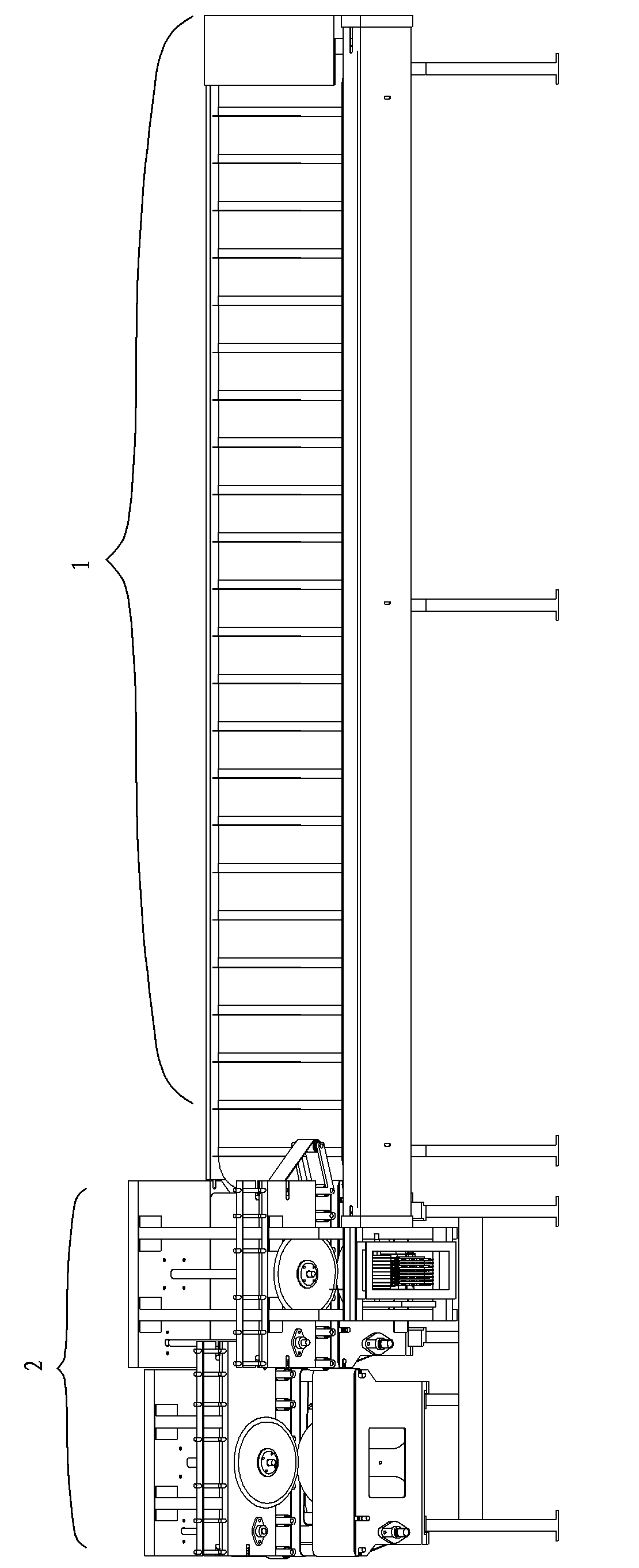

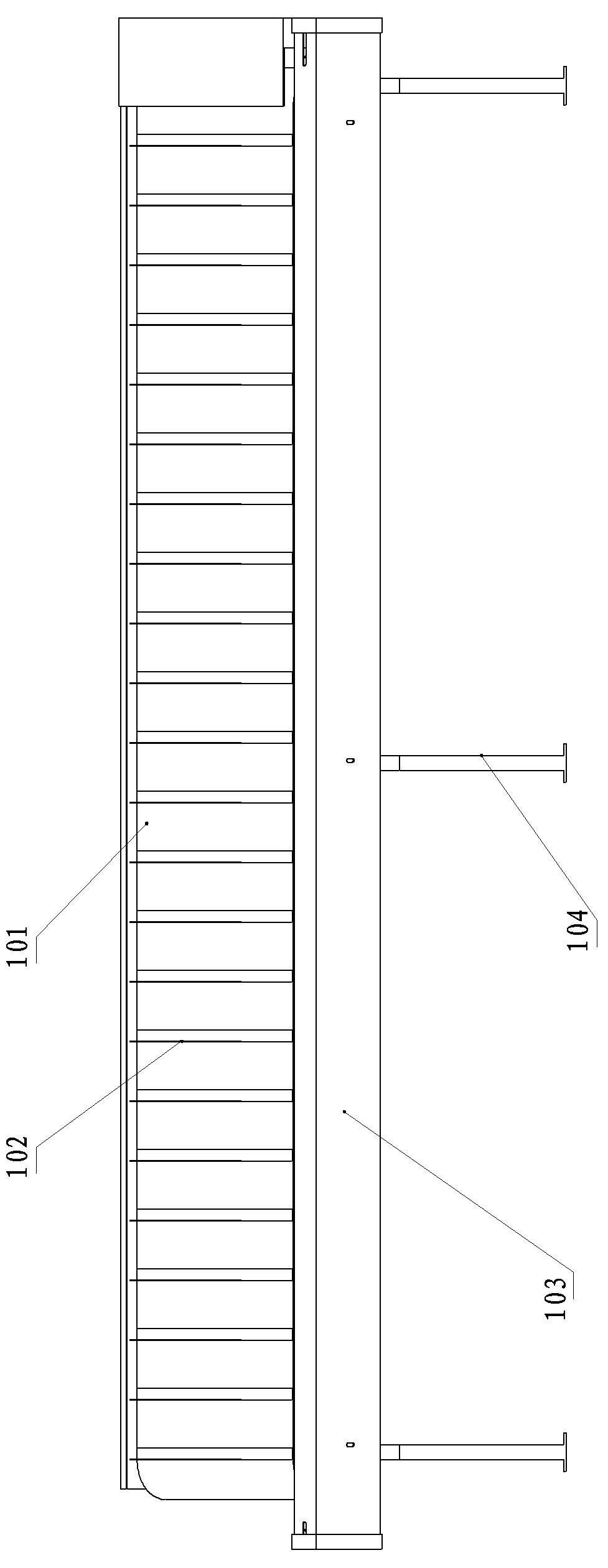

Slantwise type self-tidying integrated equipment with functions of handle cutting, handle releasing and cutting off

A tilting and cutting handle technology, applied in the field of cutting integrated equipment, unwinding, and tilting self-aligning cutting handle, can solve the problems of high equipment cost, segmented processing, and lengthy handle removal process, so as to improve work quality and improve Work efficiency, the effect of a wide range of process parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0044] Embodiment: an inclined self-aligning cutting, unhandling, and cutting integrated equipment, including a laying and feeding part and a cutting, unhandling, and cutting part. The feeding part includes a laying and feeding belt arranged obliquely And the backing belt vertically arranged with the material-laying belt, the vertical plate is evenly distributed on the material-laying belt, and the vertical plate is arranged on the material-laying belt. The handle cutting machine, the cutting machine and its support, the lower part of the cutting handle and the handle removing machine form a sliding pair connection with the support through the chute and the slide rail, and the lower part of the cutting machine forms a sliding pair with the support through the chute and the slide rail Connection, the supporting belts of the cutting handle, handle removing machine and cutting machine are on the same inclined plane as the above-mentioned laying and feeding belt, and there are driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com