Method for operating a motor vehicle while driving through a curve

A technology for motor vehicles and curves, applied in the direction of brakes, etc., can solve the problems of high yaw rate/yaw angular velocity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

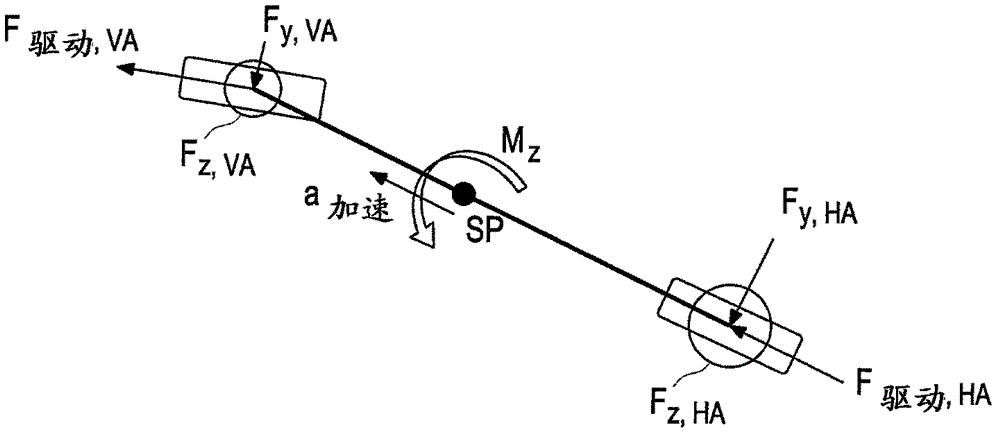

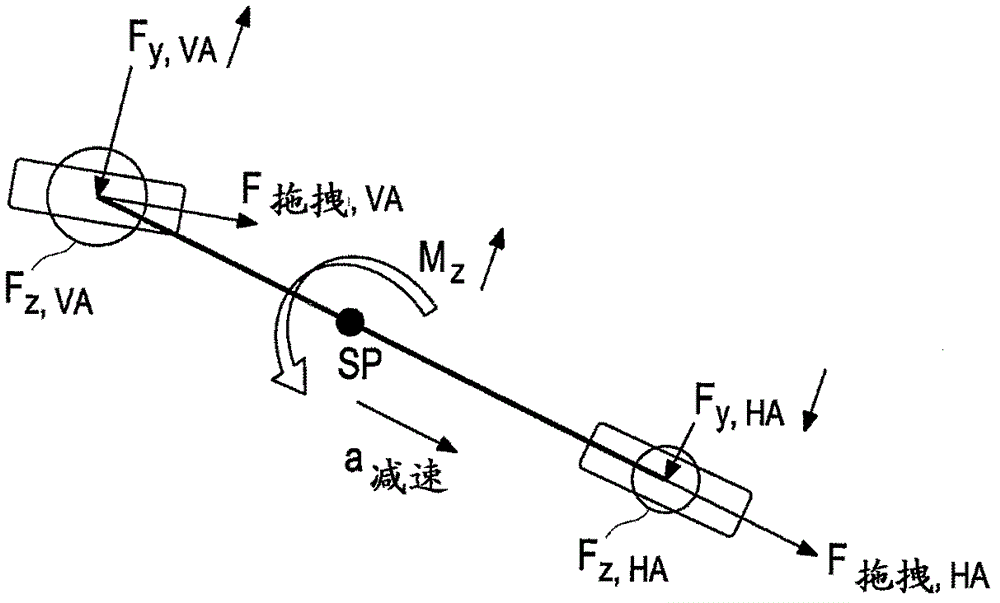

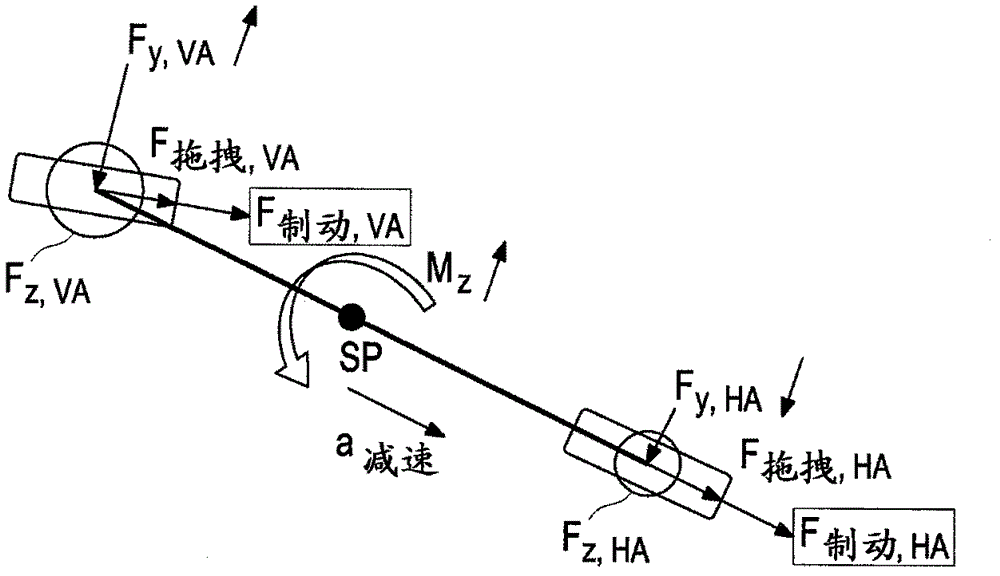

[0026] In the single track model, the wheels of (each) axle are summed in the vehicle centerline. Thus one front wheel and one rear wheel can be seen, on which the force indicated by VA acts and on which the force indicated by HA acts. Yaw moment M z Acts on the center of gravity SP of the vehicle.

[0027] according to figure 1 , during forward acceleration, the force F 驱动,VA acting on the front wheel, the force F 驱动,HA acting on the rear wheel. at forward acceleration a 加速 , the vehicle tends to pitch backwards, so that the lift force shown by the circle (the force acting downward along the vertical axis of the vehicle) is greater at the rear than at the front, see F at the rear z,HA Marked circle and preceded by F z,VA marked circle. The lifting surface (product) also increases with the lifting force (the value of the force is proportional to the diameter of the circle), so in the forward acceleration a 加速 Lateral force F acting on the rear wheel y,HA Comparable t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com