Abdominal pad folding machine

A folding machine and abdominal pad technology, which is applied in the direction of folding thin materials, thin material handling, transportation and packaging, etc., can solve the problems of low production efficiency and high labor costs, and achieve the effect of improving work efficiency and saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

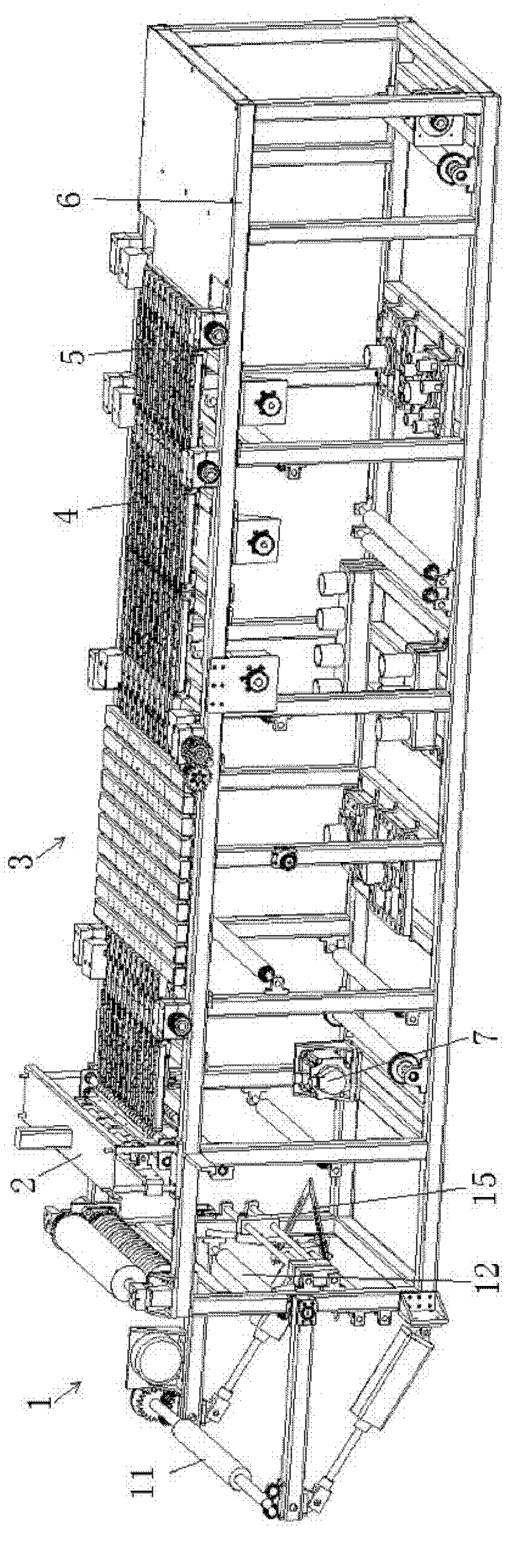

[0023] Example: see Figures 1 to 6 As shown, the abdominal pad folding machine is composed of a folding device 1, a cutting device 2, a double folding device 3, a folding device 4 and a discharge device 5,

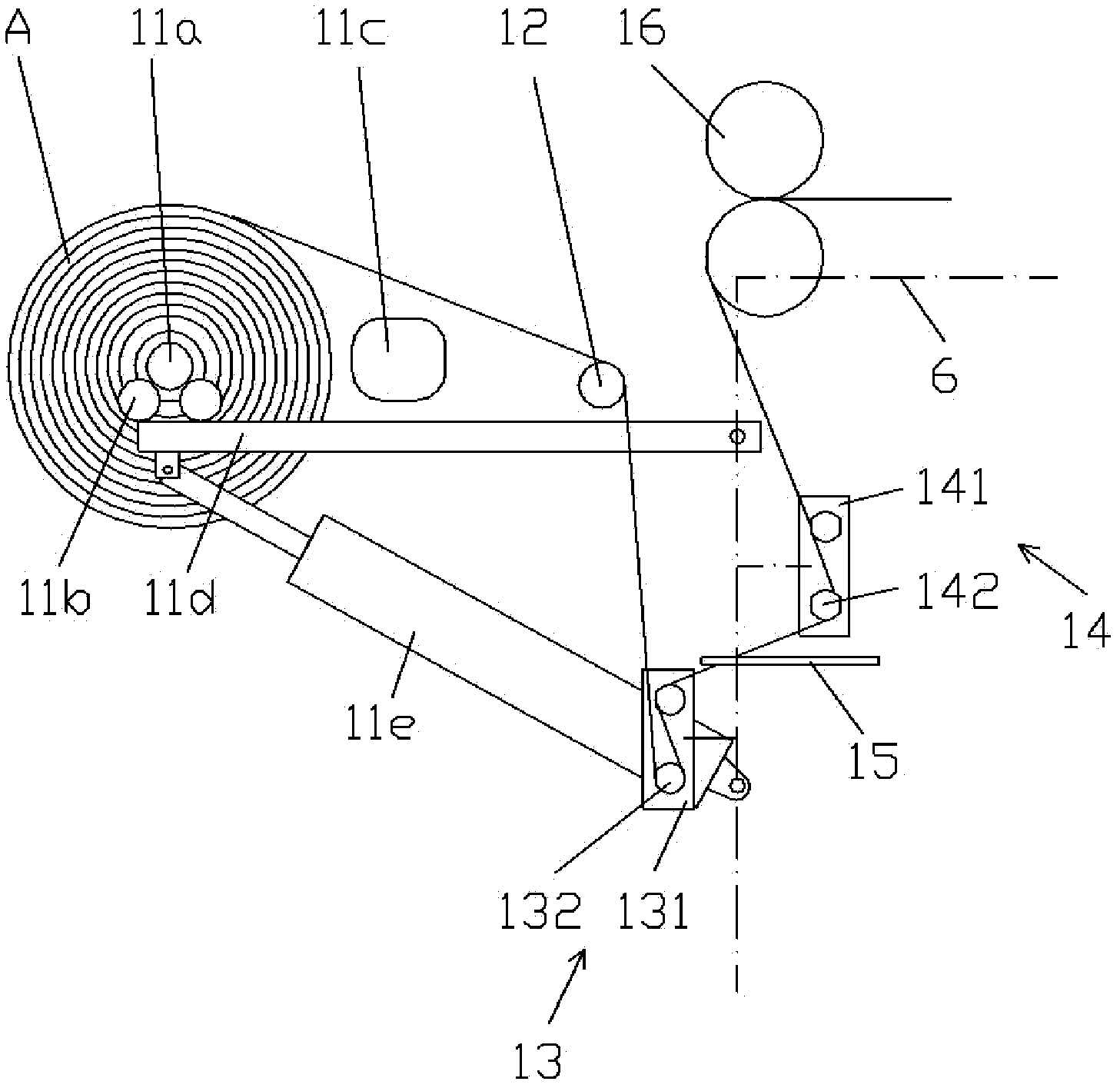

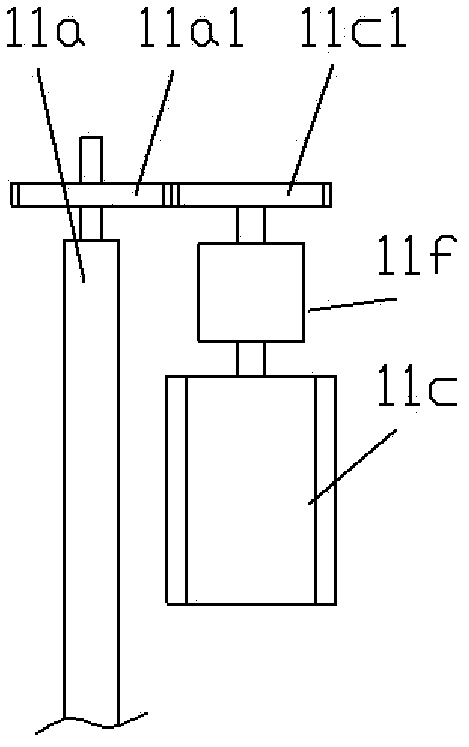

[0024] The hemming device 1 is composed of a cloth releasing roller 11, a transition roller 12, a lower frame rod 13, an upper frame rod 14, a hemming frame 15 and a cloth feeding roller 16. The cloth releasing roller 11 is composed of a cloth releasing roller shaft 11a, a pulley 11b and a Composed of a cloth motor 11c, the cloth releasing motor 11c drives the cloth releasing roller shaft 11a to rotate, the two ends of the cloth releasing roller shaft 11a are placed on the pulley 11b, the pulley 11b is installed on the roller support rod 11d, and the roller support rod 11d is hinged on the frame 6 Above, the cloth releasing cylinder 11e is hinged on the frame 6, and the piston rod of the cloth releasing cylinder 11e is hinged on the roller strut 11d; the lower frame rod 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com