Winding-up technology for fishing net loom spindle disk winding-up machine

A loom shuttle and wire take-up technology, which is applied in the direction of conveying filamentous materials, thin material processing, transportation and packaging, etc., can solve the problems of cumbersome, low wire take-up efficiency, floating fishing net line tension, etc., and achieve improved tightness Uniformity, the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

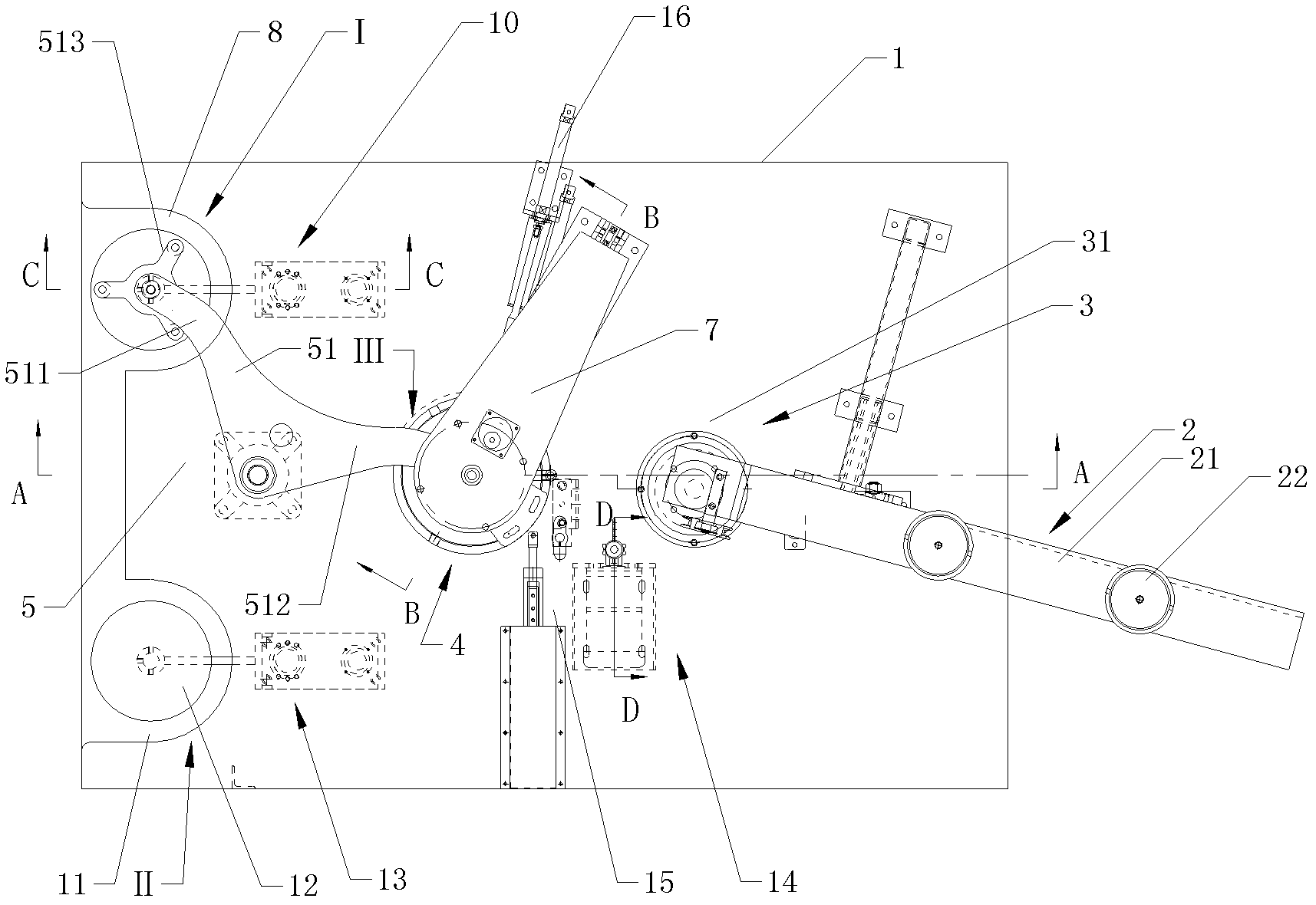

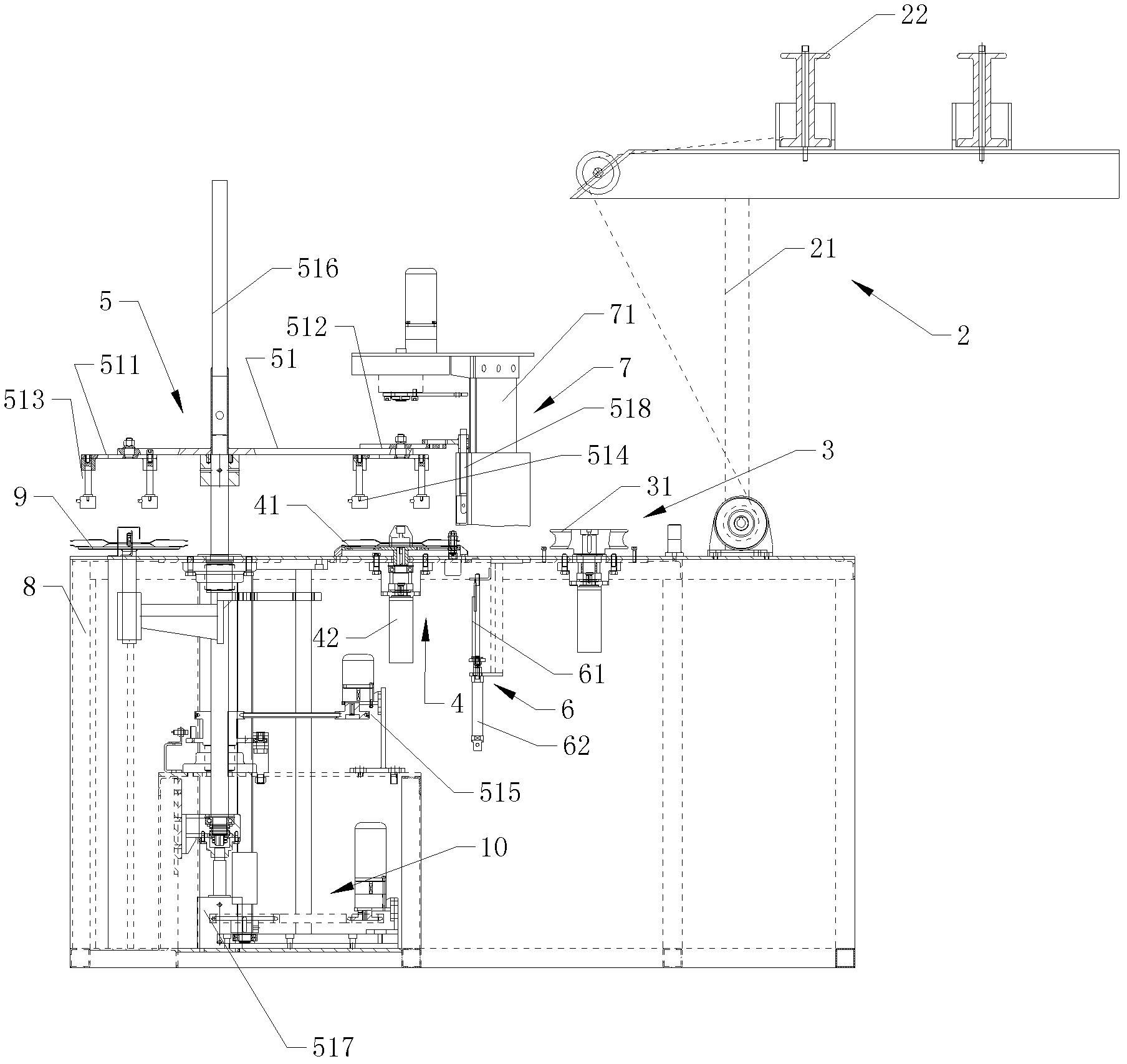

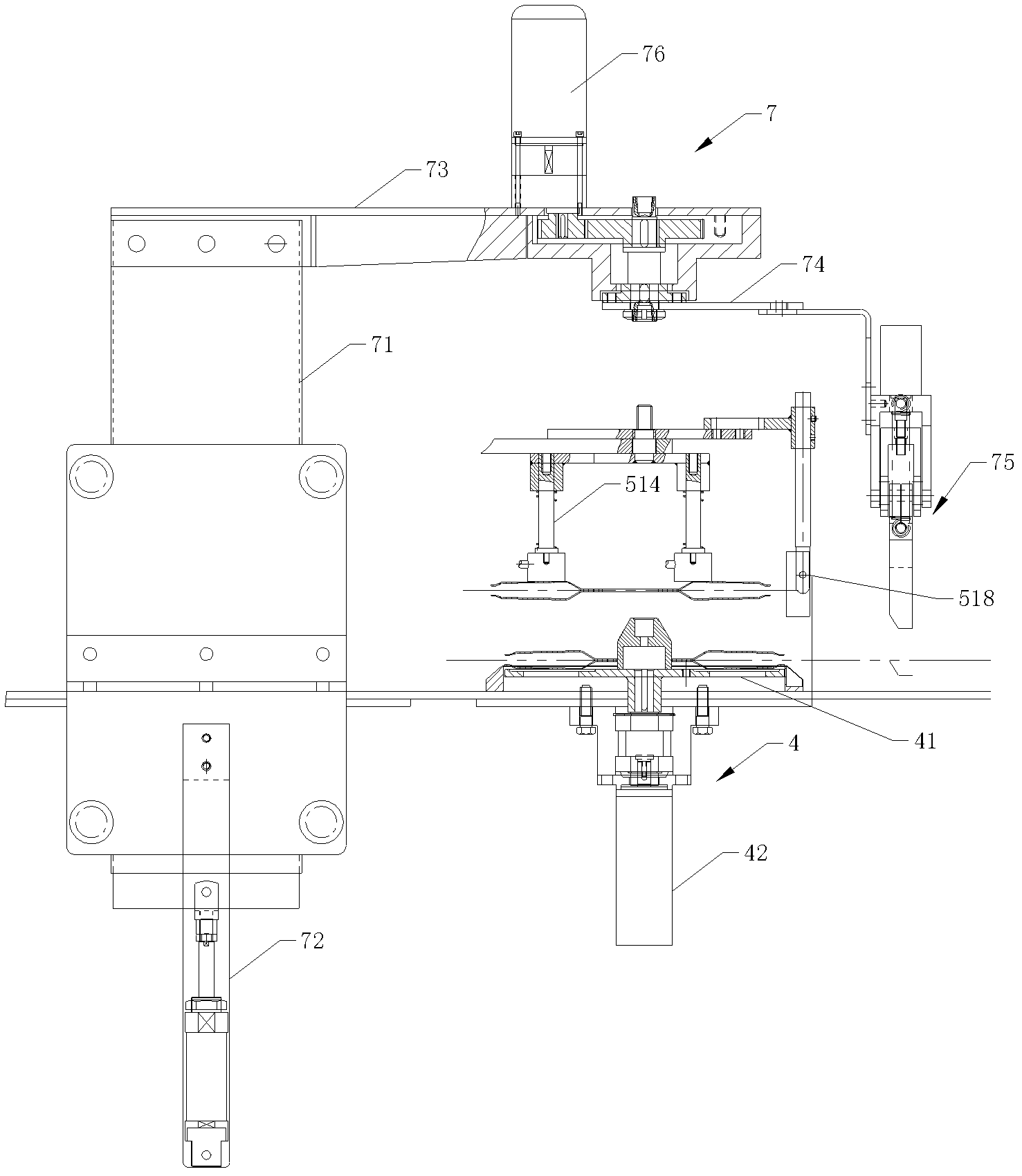

[0025] The present invention will be described in further detail below through specific examples.

[0026] The downstream and upstream mentioned in the present invention are determined by the running state of the fishing net line. The position that the fishing net line passes first is the upstream, and the position that passes through it later is the downstream.

[0027] A fishing net loom shuttle take-up machine thread take-up process, comprising the following steps:

[0028] a) Place the pay-off reel 22 winding the fishing net line on the lead frame 21, and manually pull the fishing net line through the steering wheel, the floating device 14, the traction wheel 31 and wind it to the shuttle of the take-up station III;

[0029] b) traction pulley 31 and the shuttle of take-up station III are driven by their power to rotate and draw and take-up respectively, and the floating device 14 floats up and down;

[0030] c) After the shuttle disc is full, the traction pulley 31 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com