Weft storage device without twist change

A storage device and weft storage technology, which is applied in textiles, textiles, papermaking, looms, etc., can solve the problems of poor shear strength, carbon fiber is not wear-resistant, and cannot be satisfied, so as to improve the quality of fabrics, facilitate observation, and facilitate The effect of process parameter adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

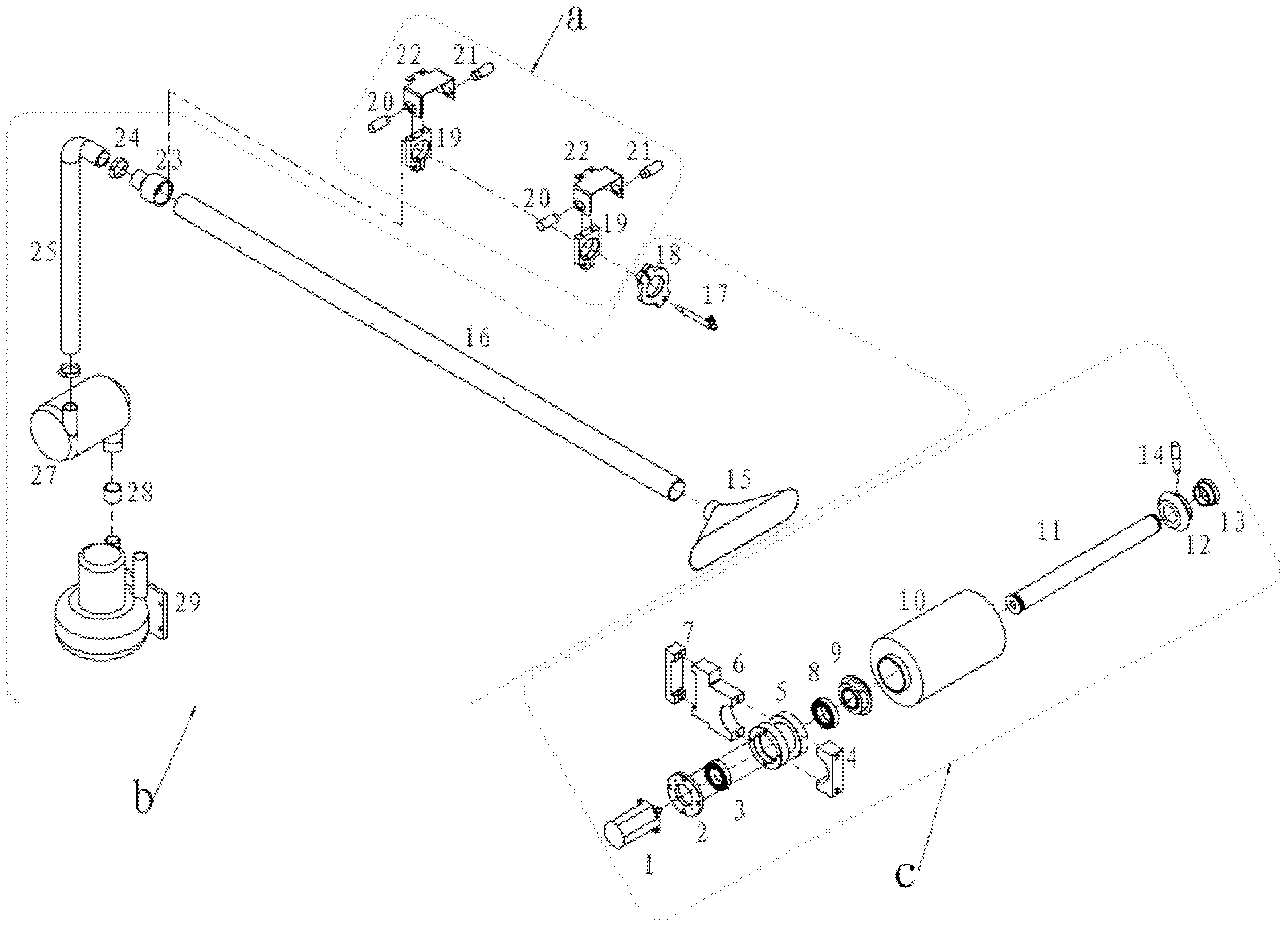

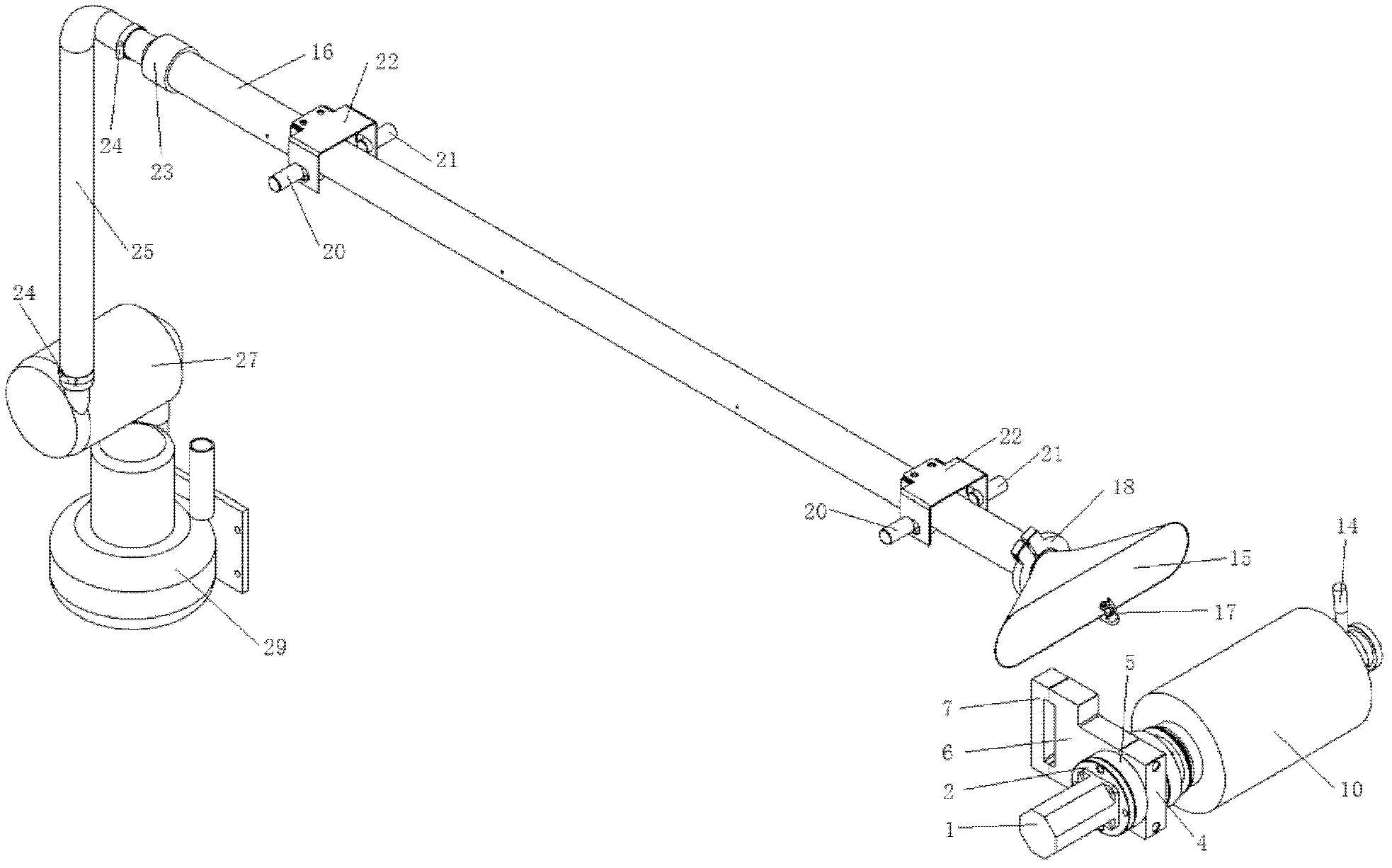

[0026] Such as figure 1 As shown, the non-twist changing weft storage device of the present invention includes an unwinding device c for unwinding the yarn; a suction storage device b for storing the unwound yarn; located in the suction storage device b On, the detection device a used to detect the normal unwinding of the yarn.

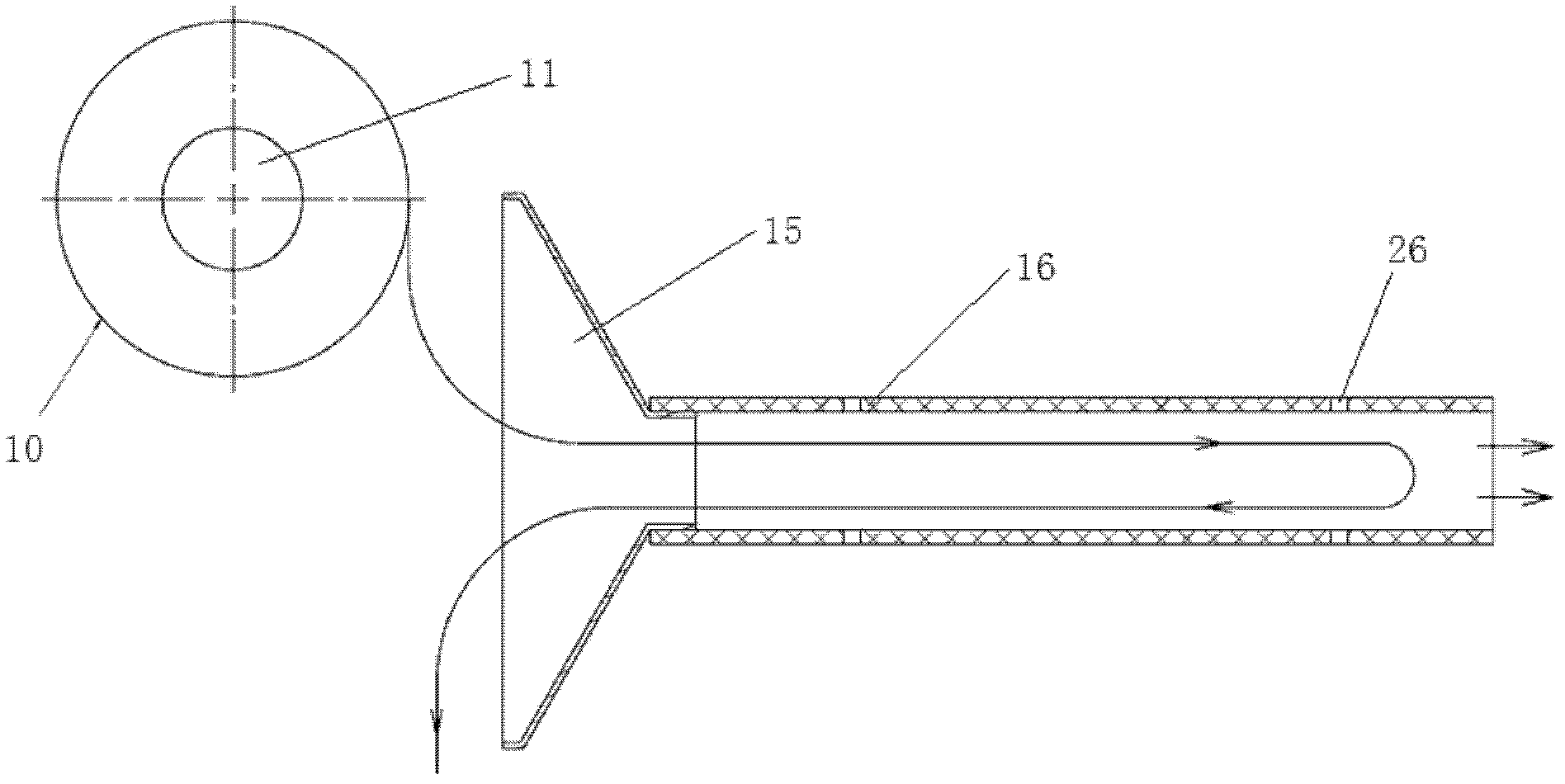

[0027] Such as figure 1 , 2 As shown, the unwinding device c includes a servo motor 1, a yarn shaft 11 connected to the servo motor 1, and a yarn bobbin 10 is fixed on the yarn shaft 11. The servo motor 1 is connected to the bearing seat 5 through the flange 2, and the yarn shaft 11 is fixed together with the bobbin 10 through the inner fixing taper sleeve 9 and the outer fixing taper sleeve 12, and the outer fixing taper sleeve 12 is provided with There is a handle 14, and a fastening nut 13 is provided at the outer end of the outer fixing taper sleeve 12. On the yarn shaft 11, a bearing seat 5 is arranged between the servo motor 1 and the bobbin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com