Siphon drainage method for tunnel wall water seepage disposal by using dipping borehole

A drainage method and tunnel technology, applied in drainage, safety devices, earthwork drilling, etc., can solve the problems of poor water collection capacity of drainage pipes and drainage holes, complicated procedures of water seepage disposal technology and methods, and affect the normal use of tunnels, etc., to achieve construction quick and easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

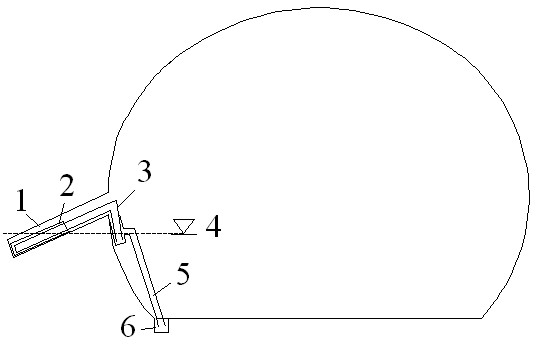

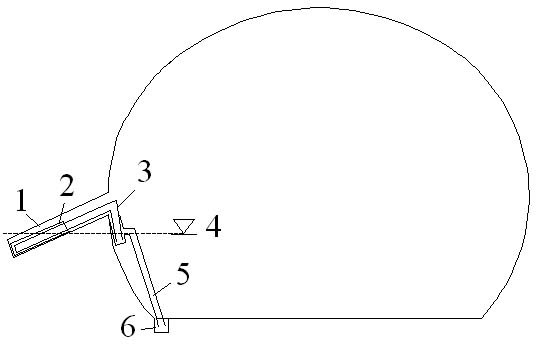

[0009] The principle of the present invention is to drill the water seepage point on the side wall of the tunnel to form a downwardly inclined borehole, so that the surrounding rock groundwater near the water seepage point can naturally seep into the borehole, and keep the relative height difference between the hole opening and the bottom of the borehole less than 8m. The siphon drainage pipe is drawn from the bottom of the inclined borehole to a certain position on the wall and fixed so that the elevation of the water inlet and outlet of the siphon drainage pipe is basically the same. The siphon process occurs, and the groundwater in the borehole is discharged into the aqueduct in real time, and then enters the drainage ditch in the tunnel to flow out of the tunnel.

[0010] The purpose and effects of the present invention will become more apparent by describing the present invention in detail below with reference to the accompanying drawings.

[0011] Such as figure 1 As sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com