Composite plane groove type condenser with high light condensation times and uniform condensation uniformity

A technology of light-gathering multiples and composite planes, applied in the direction of condensers, optics, instruments, etc., can solve problems such as inability to achieve uniform light-gathering, affect the normal use of battery panels, and enhance illumination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

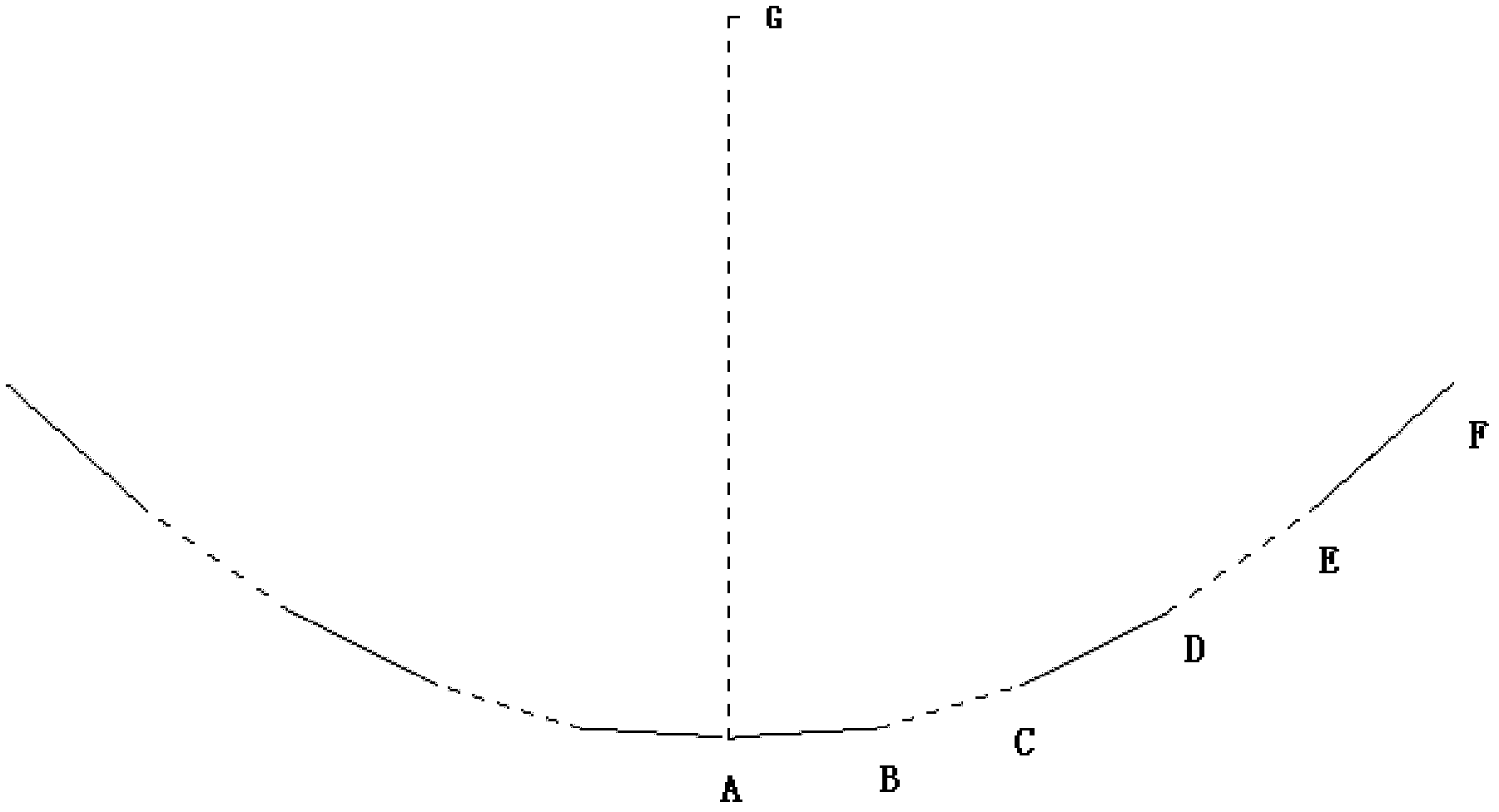

[0013] Let's explain with the help of attached drawings: figure 1 As a production example, the line segments AB, BC, CD, DE, EF are continuous line segments, AG is the symmetry axis of the parabola, and G is the focus. According to the parabolic equation x 2 =2py Set p=100mm, that is, focal length F=50mm, that is, AG=50mm

[0014] Then when x=10mm, y=0.5mm

[0015] When x=20mm, y=2.0mm

[0016] When x=30mm, y=4.5mm

[0017] When x=40mm, y=8.0mm

[0018] When x=50mm, y=12.5mm

[0019] When x=60mm, y=18.0mm

[0020] When x=70mm, y=24.5mm

[0021] When x=80mm, y=32.0mm

[0022] When x=90mm, y=40.5mm

[0023] When x=100mm, y=50.0mm

[0024] Take A(0,0), B(20,2), C(40,8), D(60,18), E(80,32) to make line segments AB, BC, CD, DE, EF, and make them Sequentially connected with the symmetrical line segment on the other side to form a continuous broken line, the continuous broken line extends along its plane to form a composite plane trough mirror. When the composite plane is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com