Urgent repair construction method for anchor mast of catenary

A catenary and anchor column technology, applied in the direction of overhead lines, etc., can solve the problems that the technology is not particularly mature and the anchor column is easy to break, so as to increase the repair time, improve the construction efficiency and reduce the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

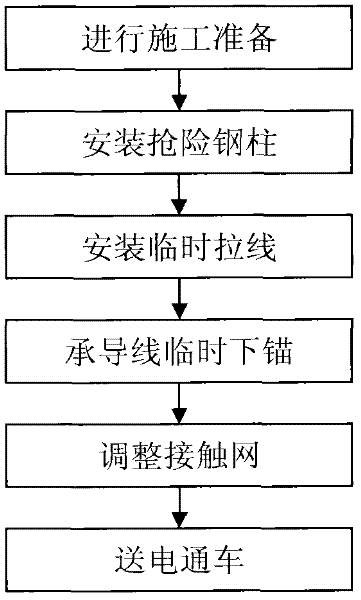

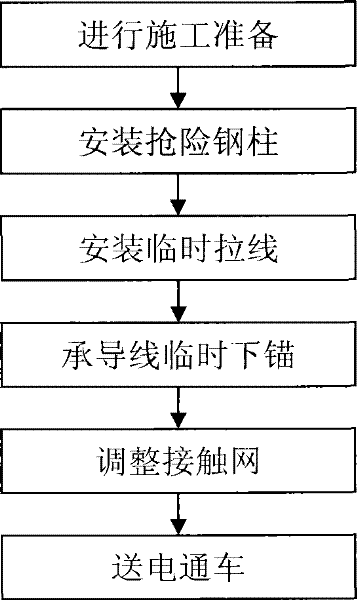

[0030] Example 1, please refer to figure 1 , this embodiment discloses a catenary anchor post emergency repair method, including the following steps:

[0031] (1) Prepare for construction:

[0032] Transport the emergency materials to the accident site, assemble the emergency steel columns on site, determine the location of the original cable pit, and excavate the cable foundation pit.

[0033] (2) Install emergency steel columns:

[0034] aFirst install the base of the emergency steel column at the broken anchor column, then install the insulating plate between the base and the rail to ensure that the rail and the base are not connected, and finally assemble the emergency steel column;

[0035] b. Connect the wrist arm upside down on the rescue steel column;

[0036] (3) Install temporary stay wires:

[0037] a. Install the anchor plate, rod and wire in the original wire pit, and pay attention to the fastening when anchoring the wire, and in the direction of the force;

...

Embodiment 2

[0049] Embodiment 2, the present embodiment changes the step (3) in the previous embodiment, puts the concrete sleeper into the original wire pit, and directly uses the steel strand to connect with the above-mentioned conversion column as the wire.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com