Automatic wire end blow-straight device of micro motor coil

A technology of micro-motors and coils, which is applied in the direction of electromechanical devices, electric components, and manufacturing motor generators. It can solve the problems of easily scratched coil paint layers, increased labor intensity, and visual fatigue, so as to avoid broken threads and improve Product pass rate, visual fatigue elimination effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

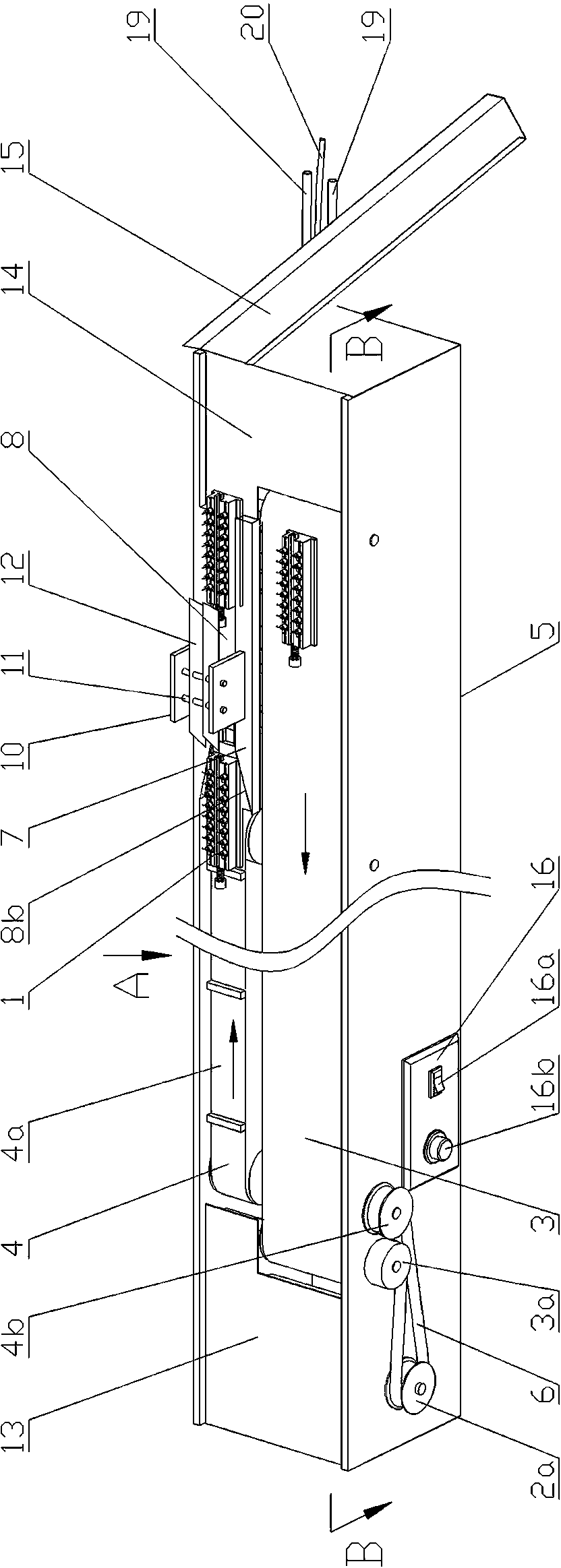

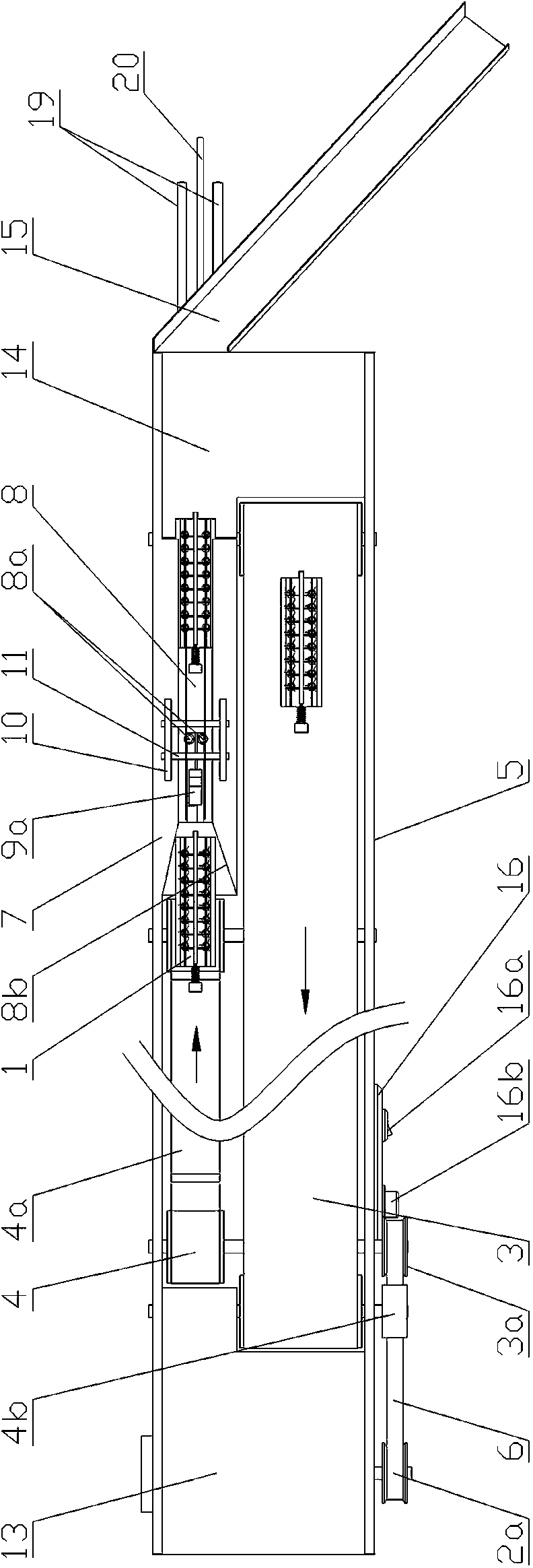

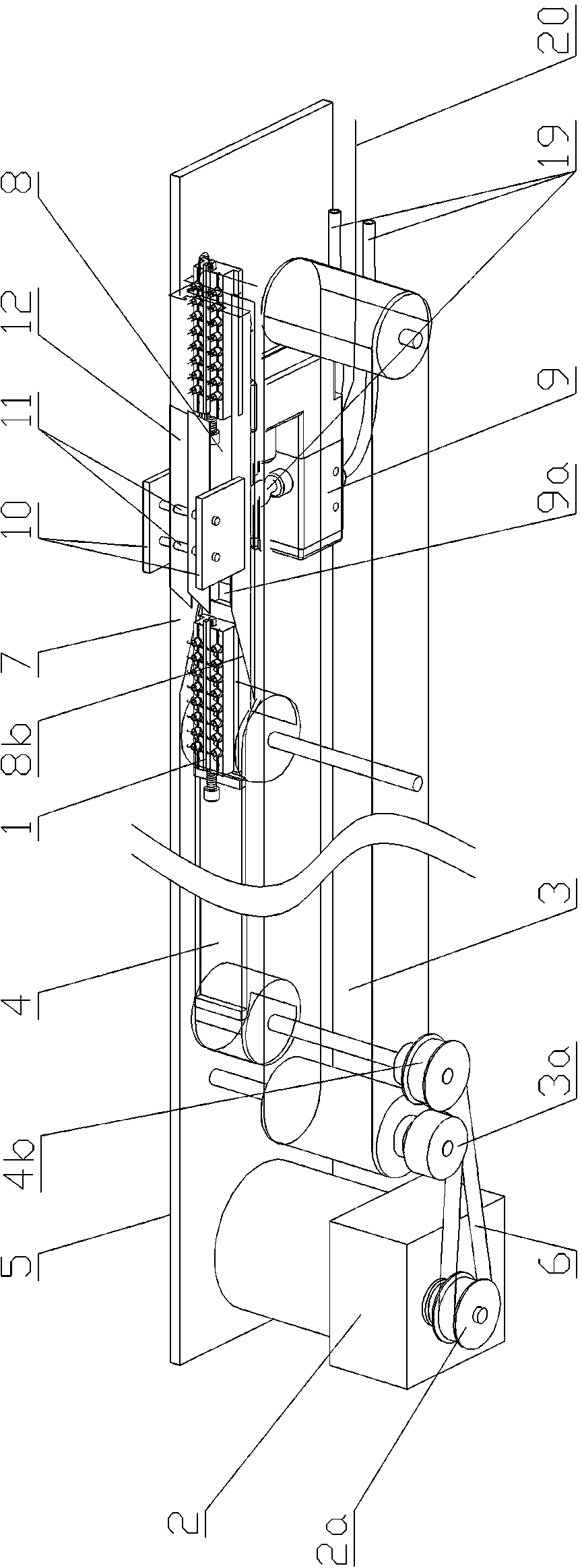

[0028] see Figure 1 to Figure 6 , an embodiment of an automatic blowing device for micro motor coils, the device includes a frame 5, a conveying device, a limit device, an air blowing device and a clamp 1 for clamping a coil.

[0029]Described conveying device is made up of motor 2, first conveyor belt 3, second conveyor belt 4, and described motor 2, first conveyor belt 3, second conveyor belt 4 are all installed on the frame 5, and wherein motor 2 is installed on frame 5 On one side, the first conveyor belt 3 and the second conveyor belt 4 are arranged side by side in the frame 5 along the lateral direction of the frame 5, and the second conveyor belt 4 is provided with a plurality of slots 4a for positioning the clamps 1 for clamping the coil. The motor 2, the first conveyor belt 3, and the second conveyor belt 4 are connected by a belt 6. In this embodiment, the motor 2 has a motor synchronous pulley 2a, the first conveyor belt 3 has a first conveyor belt synchronous pull...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com