Intelligent constant-temperature tea brewing machine and tea brewing process

A tea making machine and constant temperature technology, applied in thermometers, applications of thermometers, temperature measurement in household appliances, etc., can solve the problems of time-consuming and inconvenient, difficult to brew, and large difference in water temperature, etc., and achieve the effect of good taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

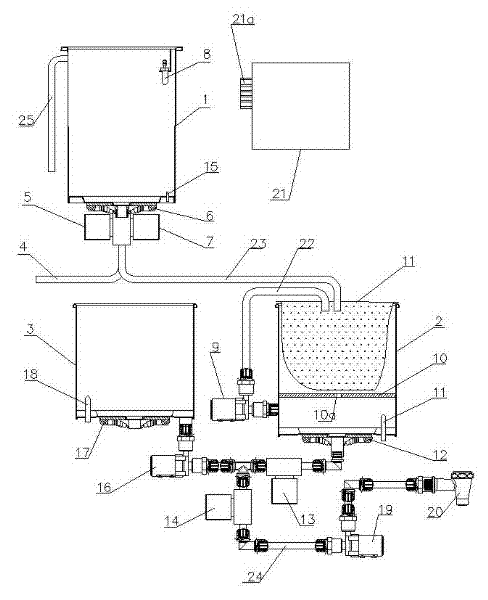

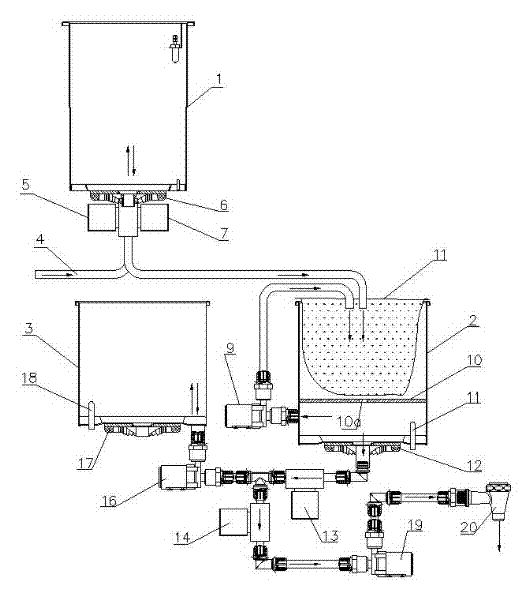

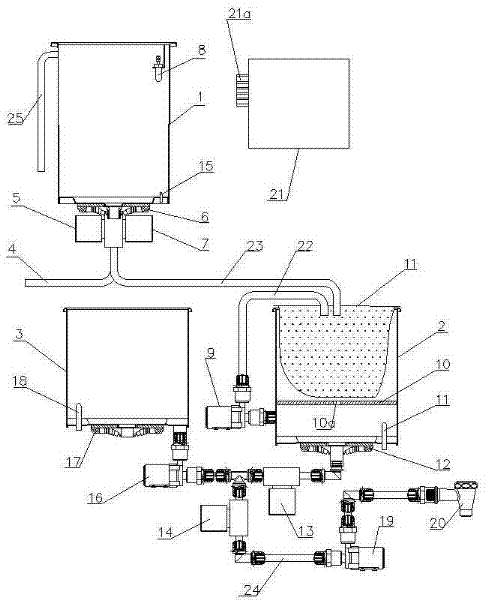

[0023] Such as Figure 1 to Figure 2 As shown, an intelligent constant temperature tea brewing machine includes a hot water tank 1, a tea brewing tank 2 and a tea storage tank 3 connected in sequence through pipelines. The tea storage tank 3 is connected to a drinking water outlet 20 through a water outlet pipe 24, and Including a controller 21 with an operation panel (not shown), the operation panel is preferably a combination of control buttons and liquid crystal display, and the bottoms of the hot water tank 1, the tea brewing tank 2 and the tea storage tank 3 are respectively equipped with adjustable cylinders. Heated heating discs 6, 12, 17, the three heating discs are all controlled by relays, and the inner bottom of the three cylinders are respectively equipped with temperature sensors 15, 11, 18 that can detect the water temperature, and the three temperature sensors are stainless steel packaged heat sinks. Ministor; the bottom of the tea-making tank 2 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com