Air injection booster handheld shower head

A technology of air injection and hand flower, which is applied in spraying devices, liquid spraying devices, etc. It can solve the problems of reduced air suction capacity of showers, reduced water output, and reduced air injection boosting effect, so as to prevent the breeding of bacteria and the formation of scale , Improve the effect of inhalation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings.

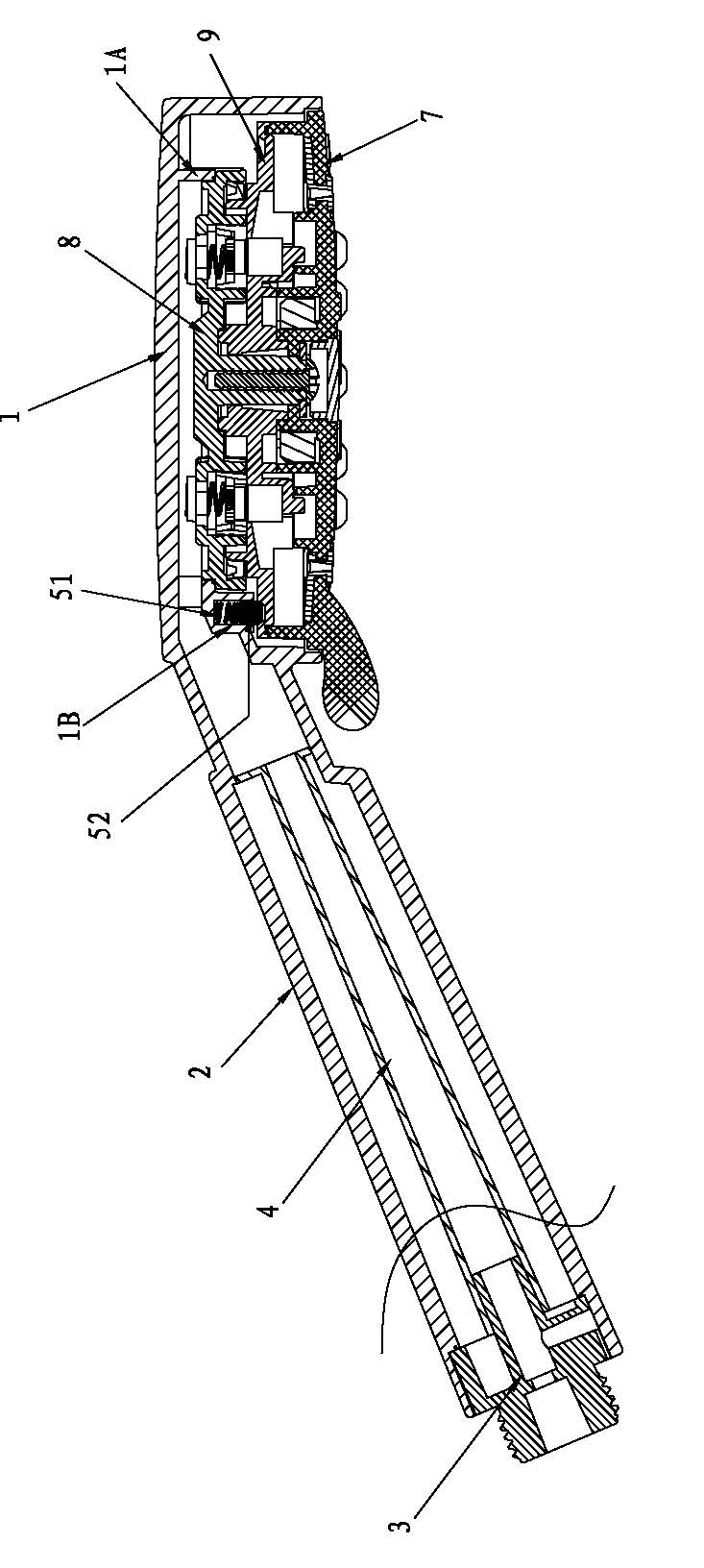

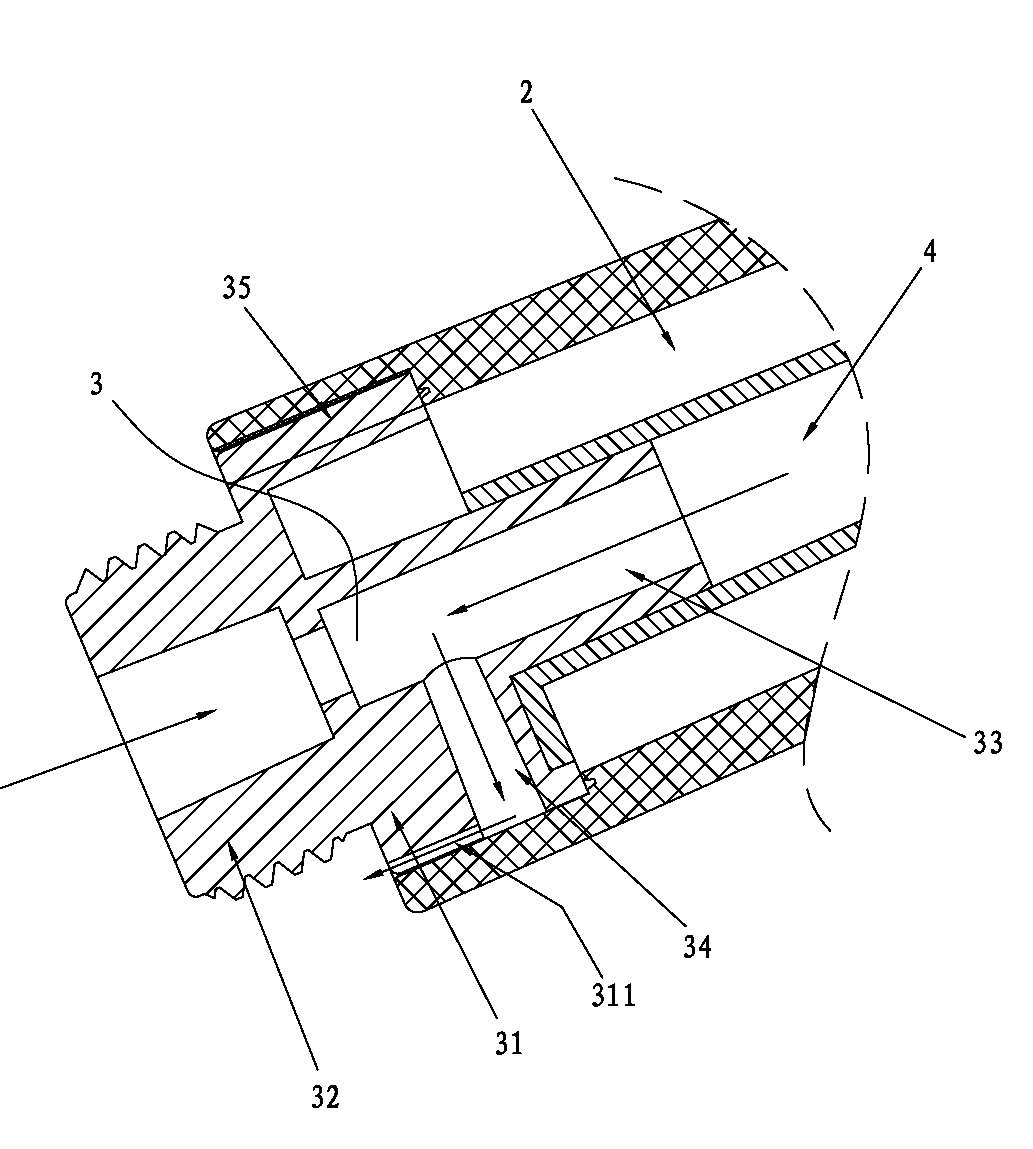

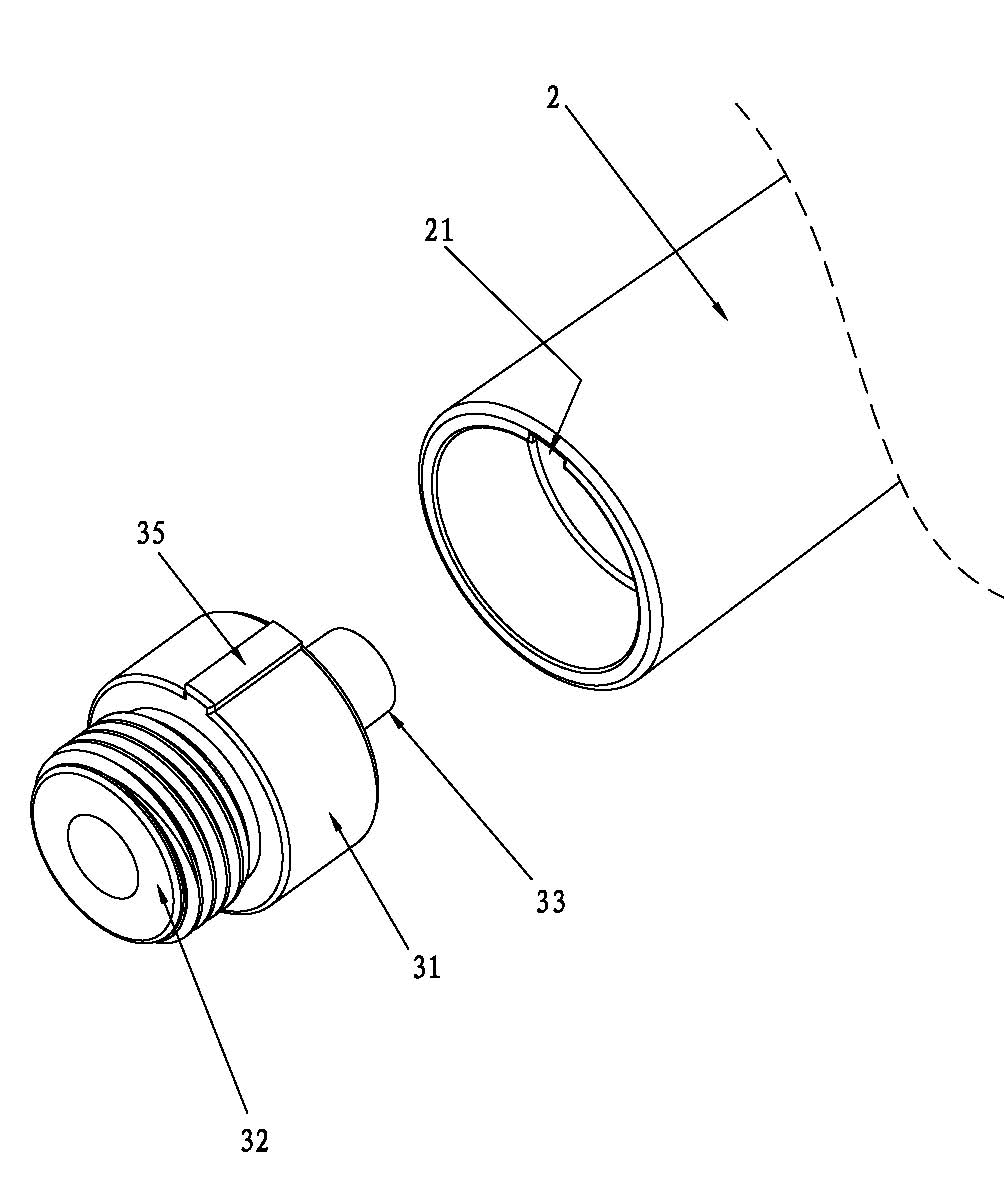

[0033] Such as figure 1 , figure 2 , image 3 As shown, an air-injected pressurized portable shower includes a housing 1, a hollow handle 2, a venturi tube 3 and a water outlet assembly arranged in the lower opening of the housing. The housing 1 and the handle 2 are integrally formed. , the Venturi tube 3 is arranged at the end of the handle 2; one end of the Venturi tube 3 communicates with the water source, and the other end communicates with the cavity between the top plate of the housing 1 and the water outlet assembly; the Venturi tube 3 includes a body 31, The water inlet interface 32 and the water outlet interface 33, the body 31 has an air inlet hole 34 along the radial direction, and an axial positioning rib 35 is arranged on the outer peripheral surface; the inner wall of the opening end of the handle 2 has a positioning groove 21 , the positioning rib 35...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com