Atomizing dish washing machine

A dishwasher and spray technology, which is applied to the washing machine/washing machine of tableware, parts of the washing machine/rinsing and washing machine of tableware, cleaning equipment, etc., can solve the problem of poor drying effect, polluted tableware, high-power air pressure Problems such as the large size of the machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

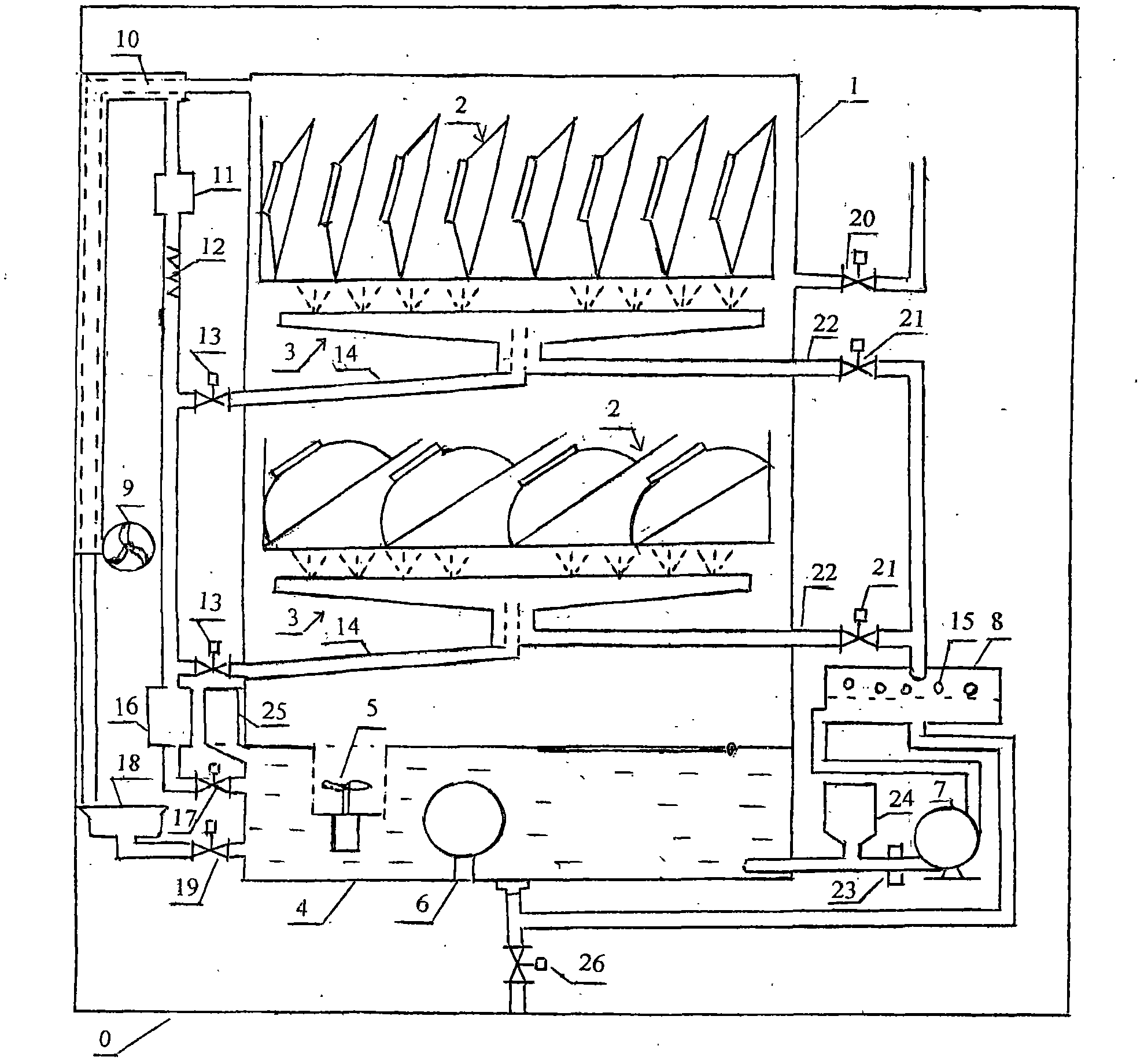

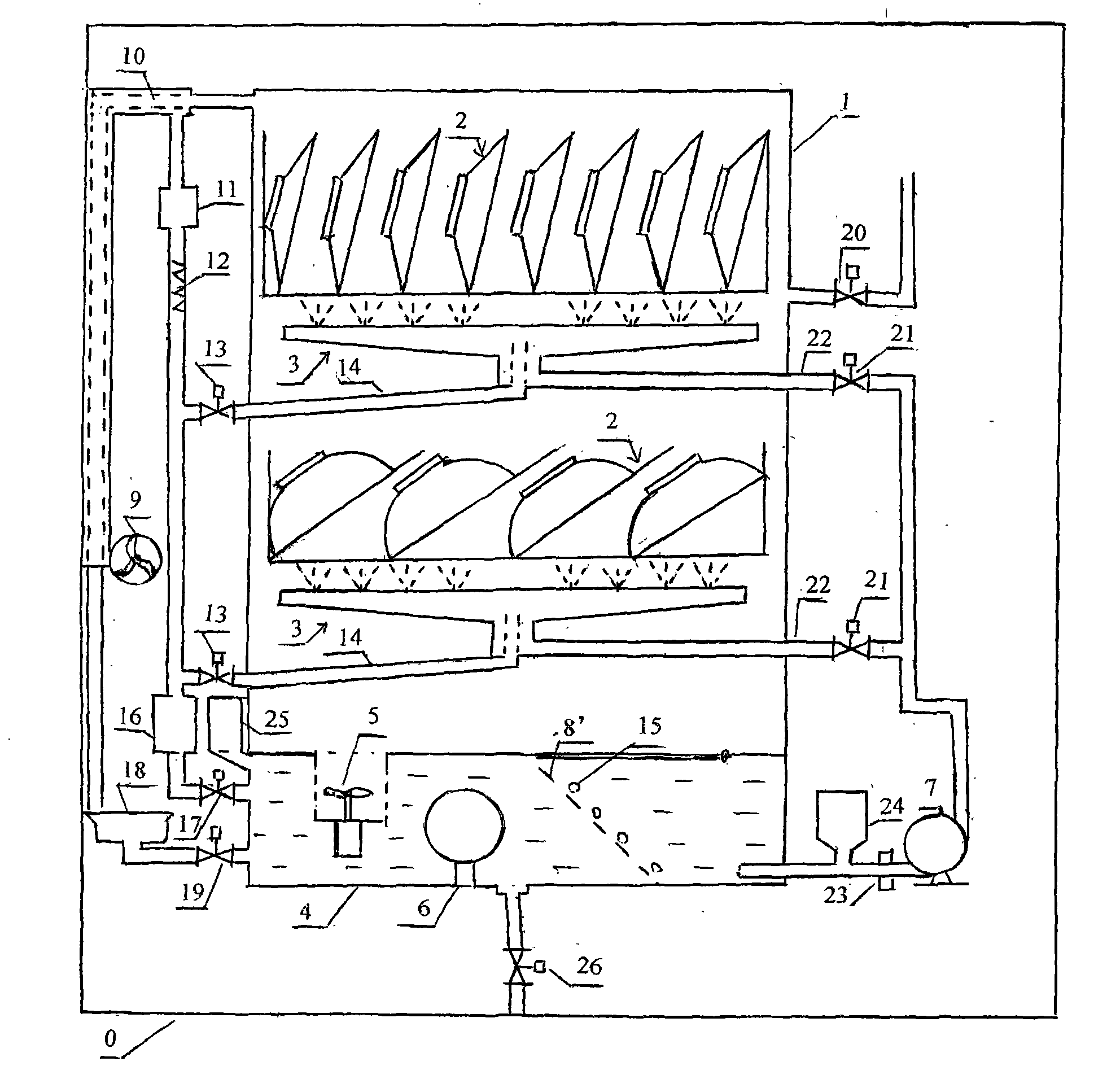

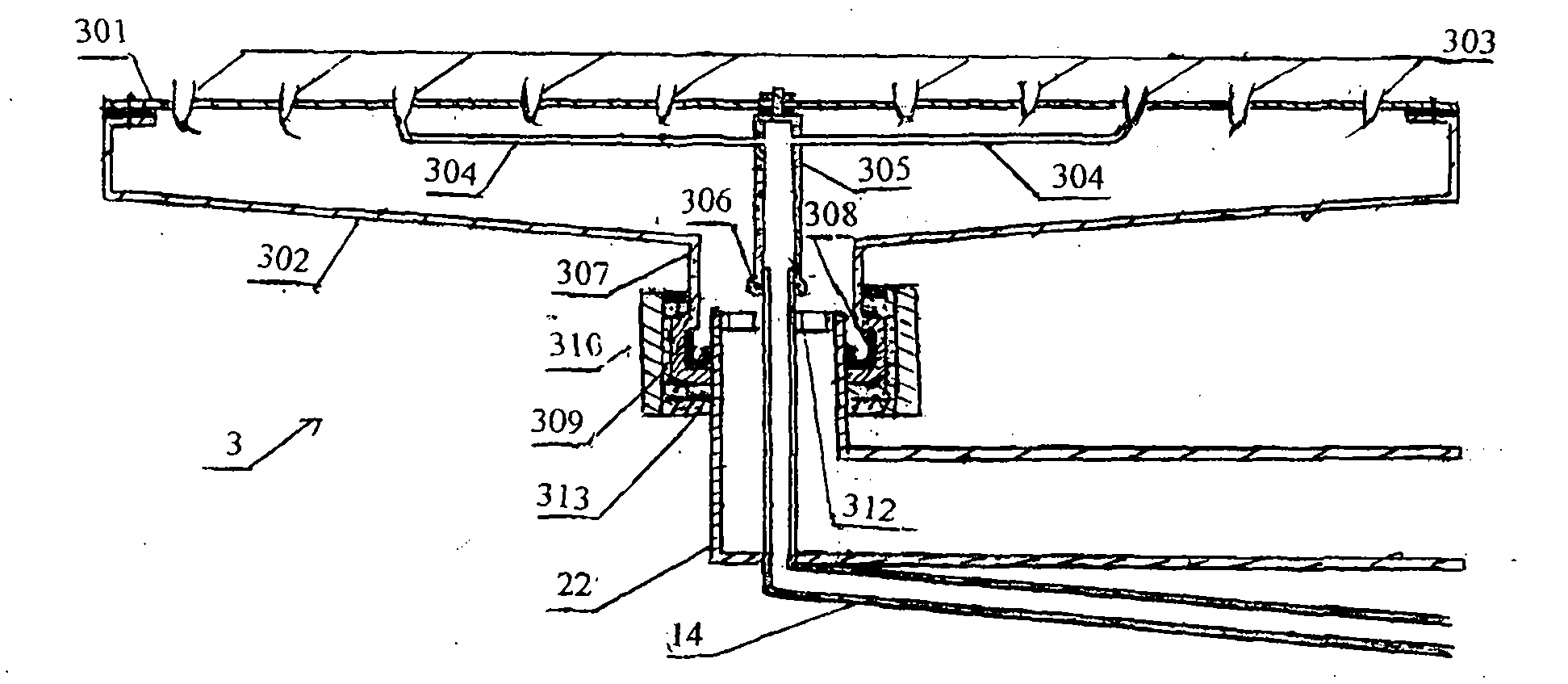

[0014] picture, figure 2As shown, the household spray dishwasher in the present invention includes: a housing 0, an inner box 1, a bowl basket 2, a water pump 7, a pool 4, a rotating spray arm 3, a turbidity detection sensor 23, a dishwashing powder dispensing device 24, Rinse agent dispensing device 25, air outlet condensing pipe 10, water inlet solenoid valve 20, drain solenoid valve 26, filter device, electric heating tube 6, electric heating wire 12, sniffing oxygen generator 11, water outlet solenoid valve 21, water outlet pipe 22 , Stirrer 5, temperature sensor, water level sensor and computer controller. The rotating spray arm 3 is contained in the inner case 1, and the bowl basket 2 is placed on the inner case 2 track above the rotating spray arm 3, and the pool 4 is contained below the inner case 1. Tee is equipped with below the water outlet of the bottom of pool 4, drain solenoid valve 26 is housed at the lower end interface of tee, and the water outlet of drain s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com