Non-contact power supply device provided with temperature sensor

A temperature sensor, non-contact power supply technology, applied in the direction of using electrical devices, inductors, thermometers, etc., can solve the problems of difficult to accommodate the housing, difficult to measure accurate temperature, low responsiveness, etc., to prevent excessive heat generation, easy to ensure , the effect of high thermal responsiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

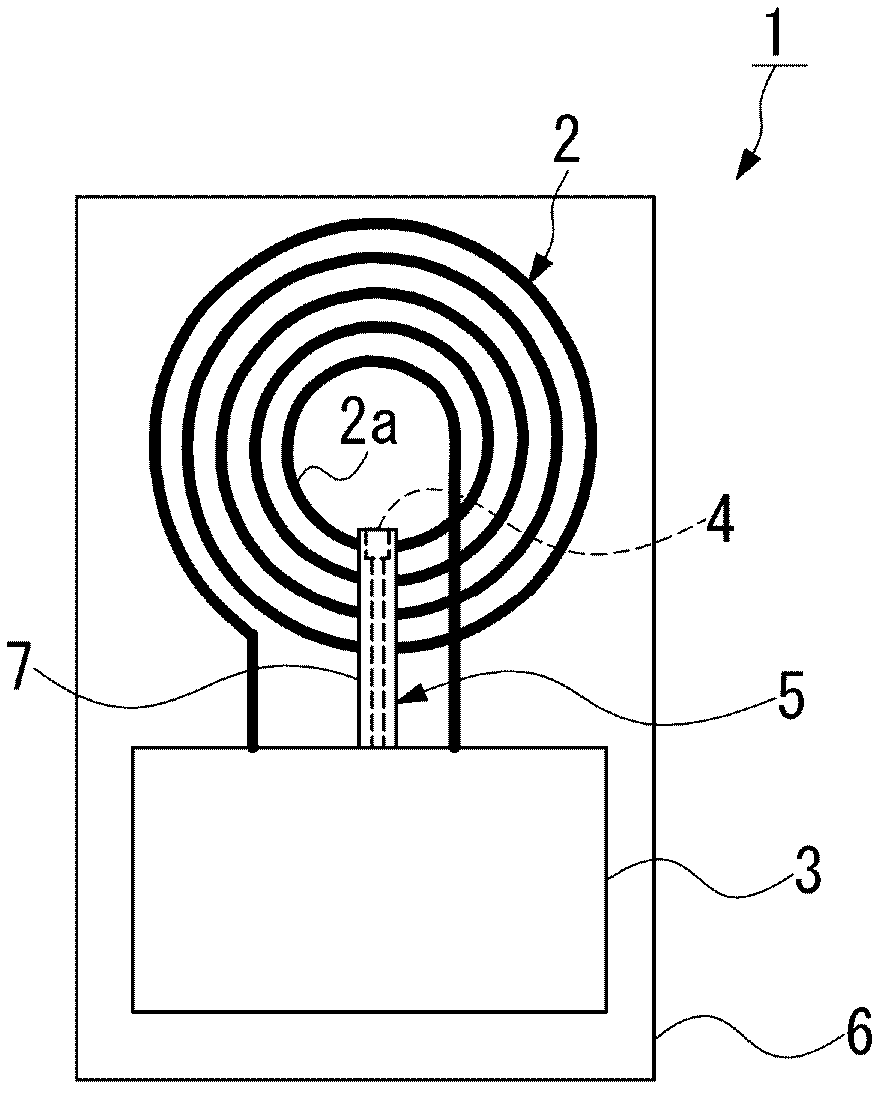

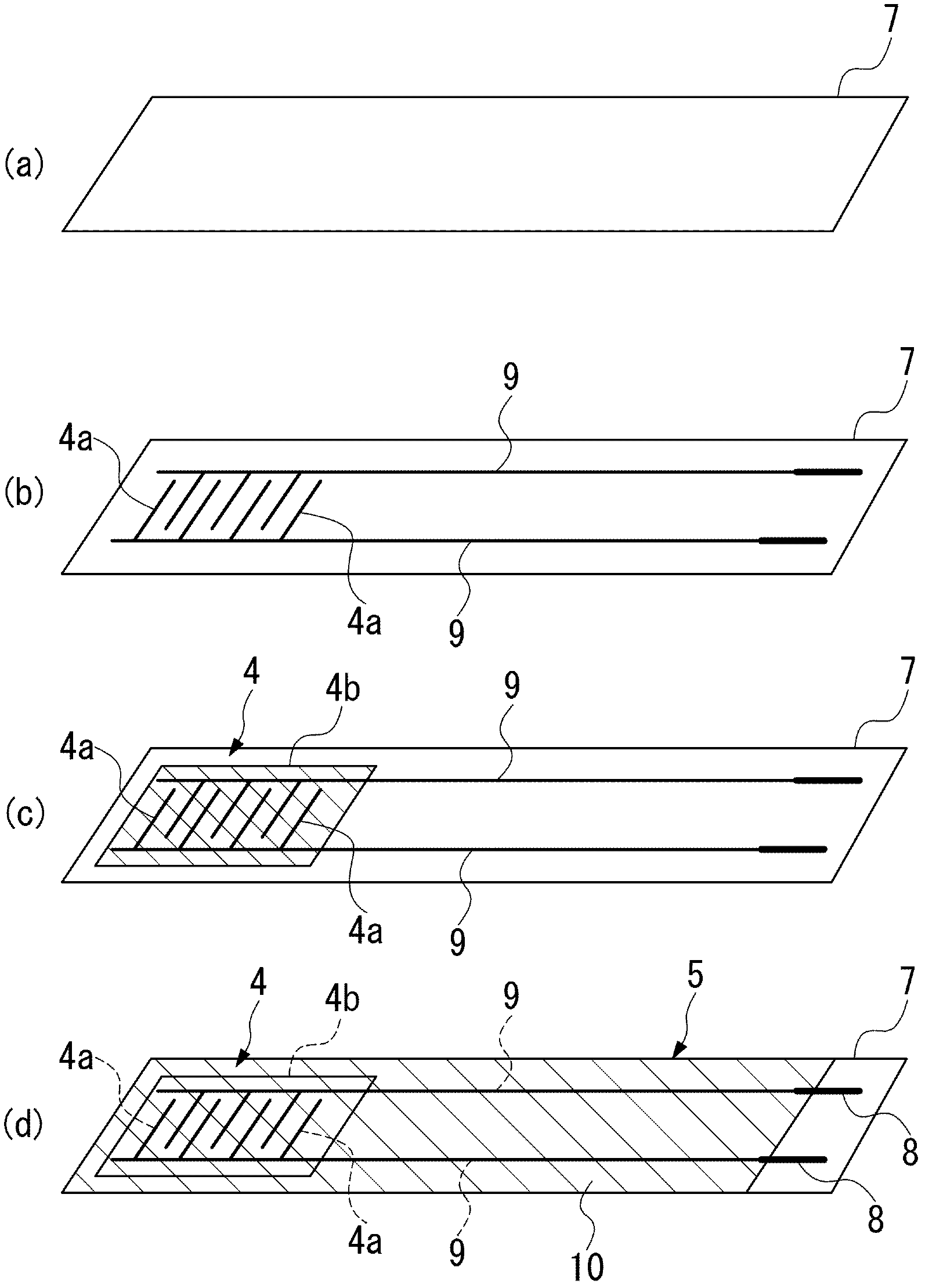

[0028] Below, reference Figure 1 to Figure 4 The first embodiment of the non-contact power supply device with temperature sensor according to the present invention will be described. In addition, in each drawing used in the following description, the scale is appropriately changed in order to make each component a recognizable or easily recognizable size.

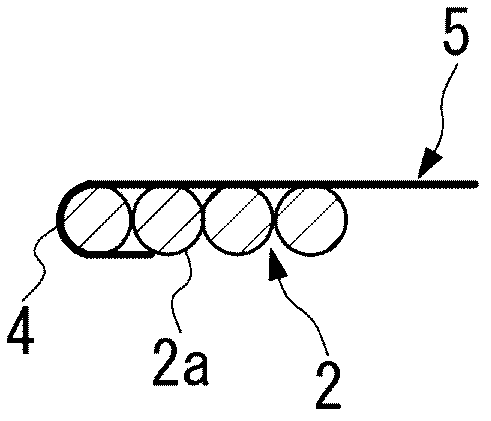

[0029] Such as figure 1 and figure 2 As shown, the non-contact power supply device 1 with a temperature sensor of this embodiment includes a transmission coil 2 composed of a spiral winding wire 2a and a circuit unit 3 that controls the AC voltage applied to the transmission coil 2. 2 Apply an AC voltage and transmit electric power to a powered device or a charged device through electromagnetic induction. Among them, a film-shaped temperature sensor 5 is provided with a heat sensitive part 4 provided in the transmission coil 2 and whose resistance changes according to temperature.

[0030] In addition, the non-contact power s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com