Gas purifying device

A gas purification device and gas technology, applied in chemical instruments and methods, using liquid separation agents, and separation of dispersed particles, can solve problems such as environmental pollution, flue fouling, and high cost, and achieve cost reduction and emission reduction The effect of increasing the amount and contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

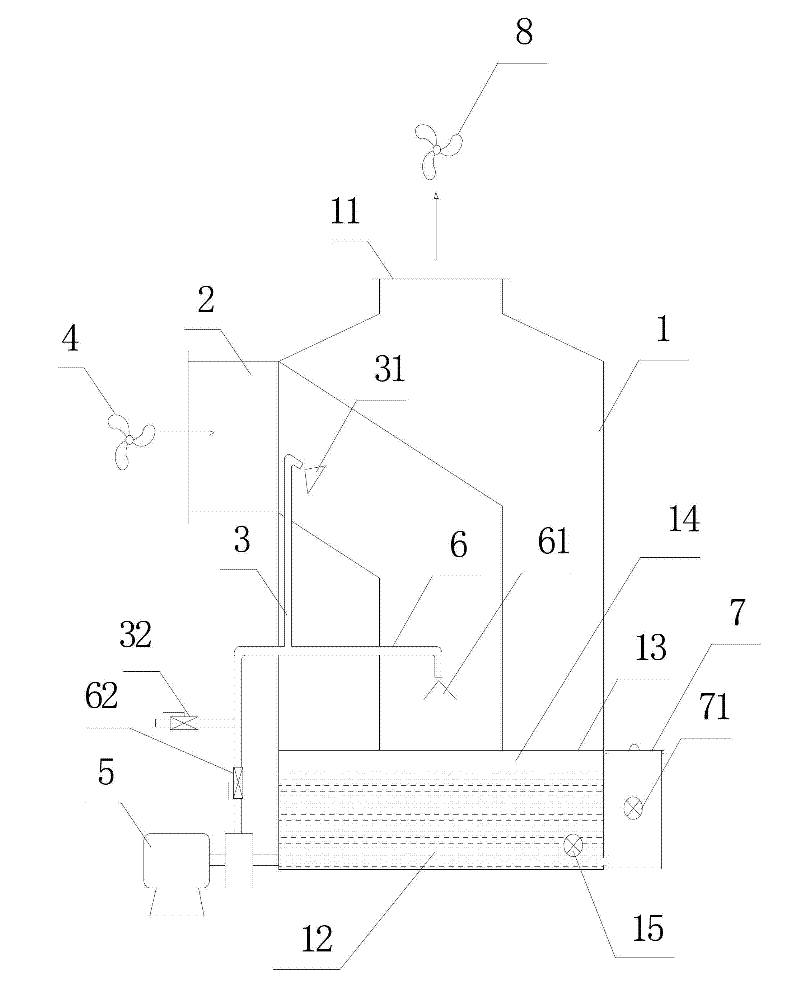

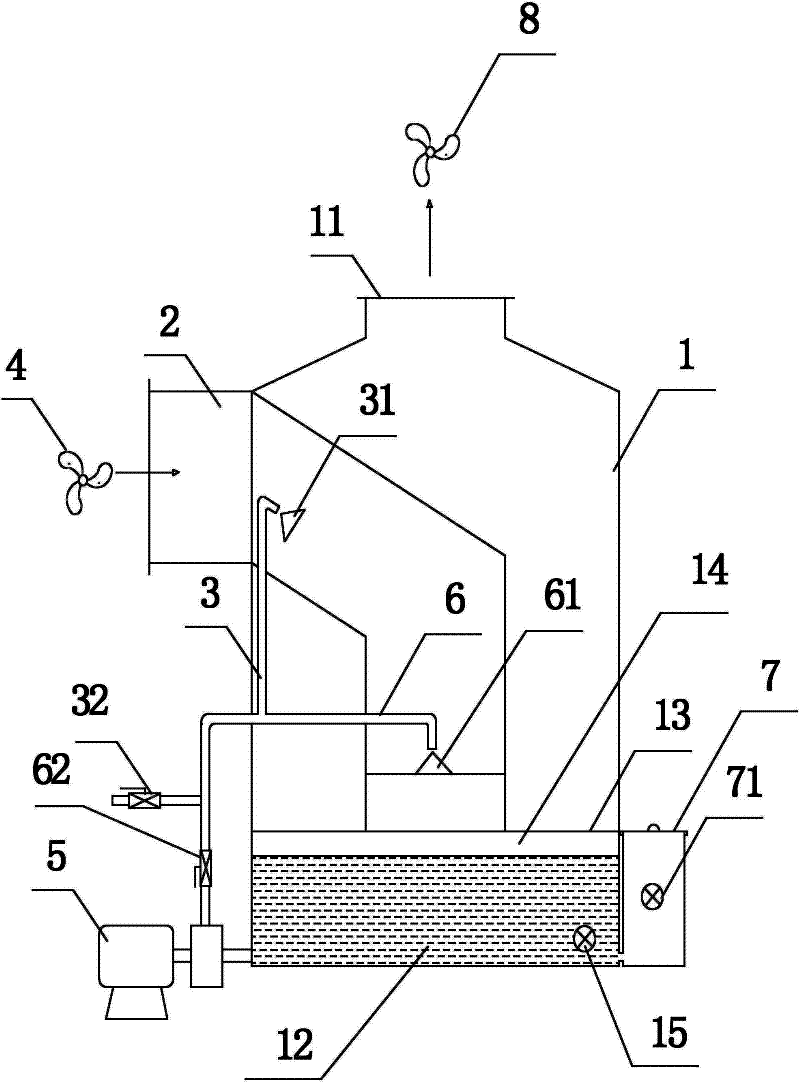

[0024] Such as figure 1 Shown, a kind of gas purification device comprises:

[0025] An outer tower 1, an exhaust port 11 is arranged on the top of the outer tower, a liquid storage chamber 12 is arranged at the bottom, a gas distribution net 13 is arranged above the liquid storage chamber 12, and a purification chamber 14 is formed between the gas distribution net and the liquid surface of the liquid storage chamber ;

[0026] A backflow device 2, the backflow device is embedded into the outer tower 1, and the end of the backflow device is attached to the gas distribution network 14;

[0027] A liquid inlet pipe 3, the liquid inlet end of the liquid inlet pipe 3 communicates with the liquid storage chamber 12, the liquid outlet end is nested into the inclined section of the backflow device, and the first liquid separation cone 31 is provided at the liquid outlet port;

[0028] The gas to be purified is passed into the backflow device 2 under the action of a fan 4, and the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com