LED (Light Emitting Diode) light guide structure

A light guide structure, LED light source technology, applied in the direction of light source, light source fixed, point light source, etc., can solve the problems of easy loss, inability to become a light-emitting module, insufficient brightness, etc., and achieve the effect of increasing brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The detailed description and technical content of the present invention are described below with the accompanying drawings, but the attached drawings are only for reference and illustration, and are not used to limit the present invention.

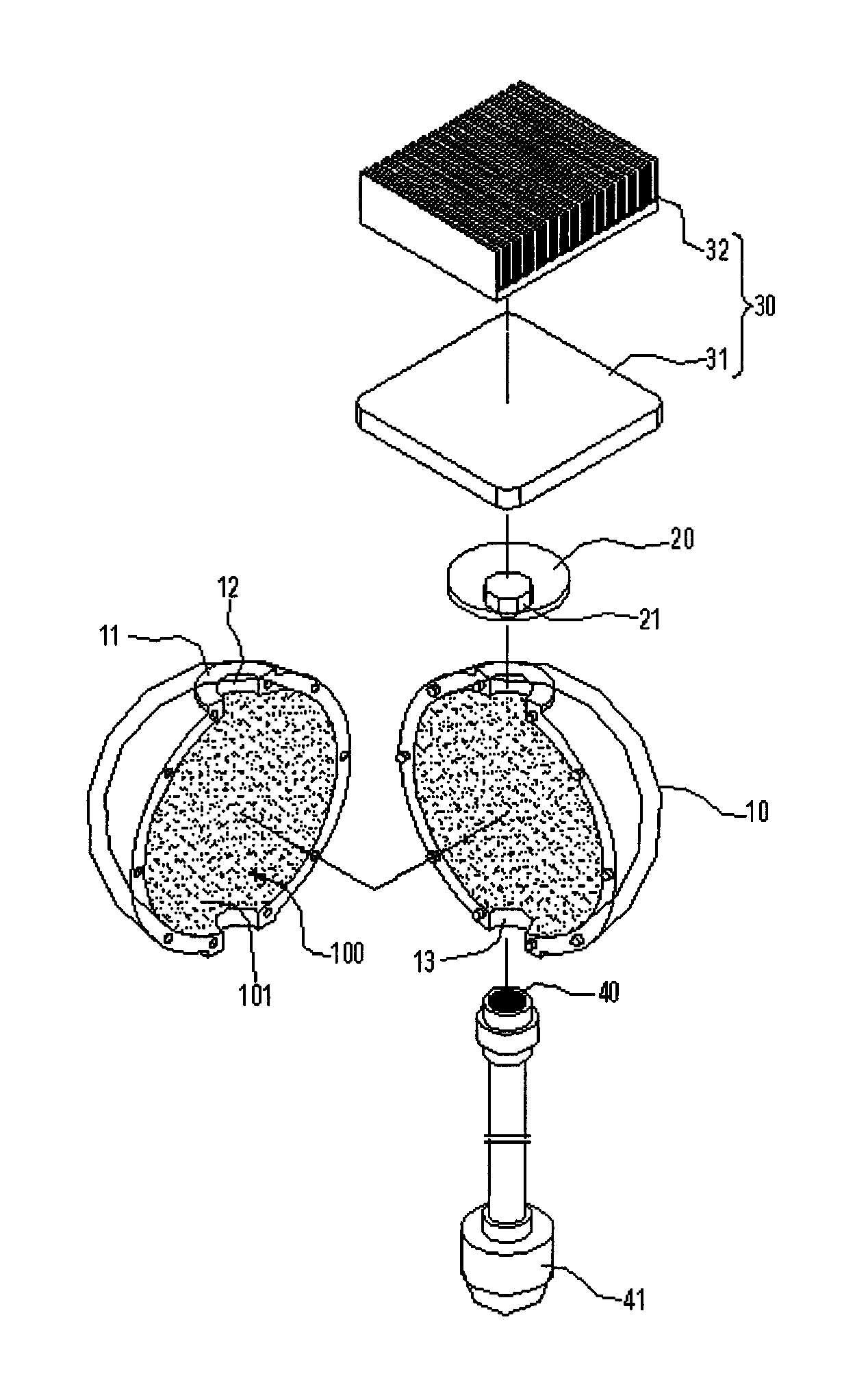

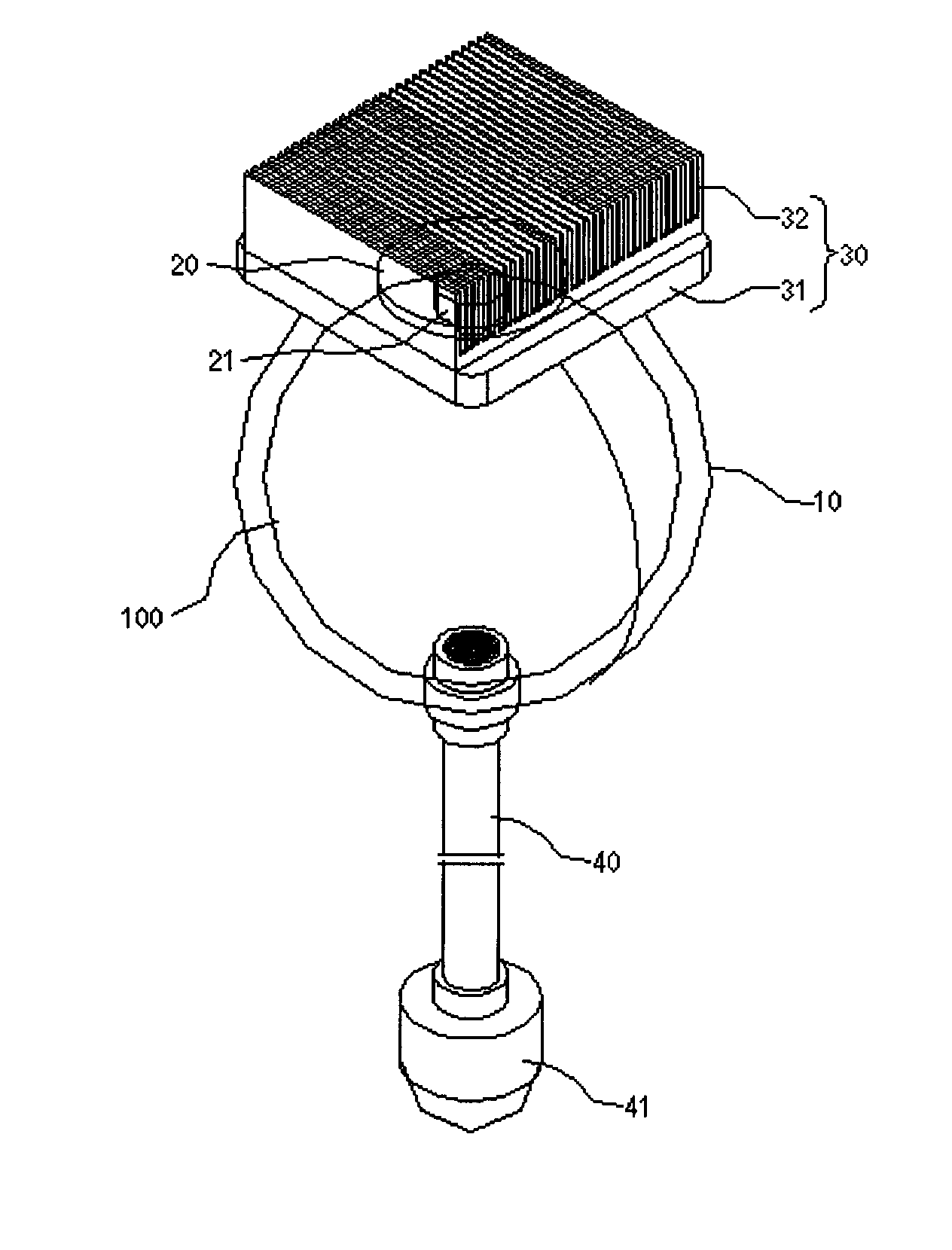

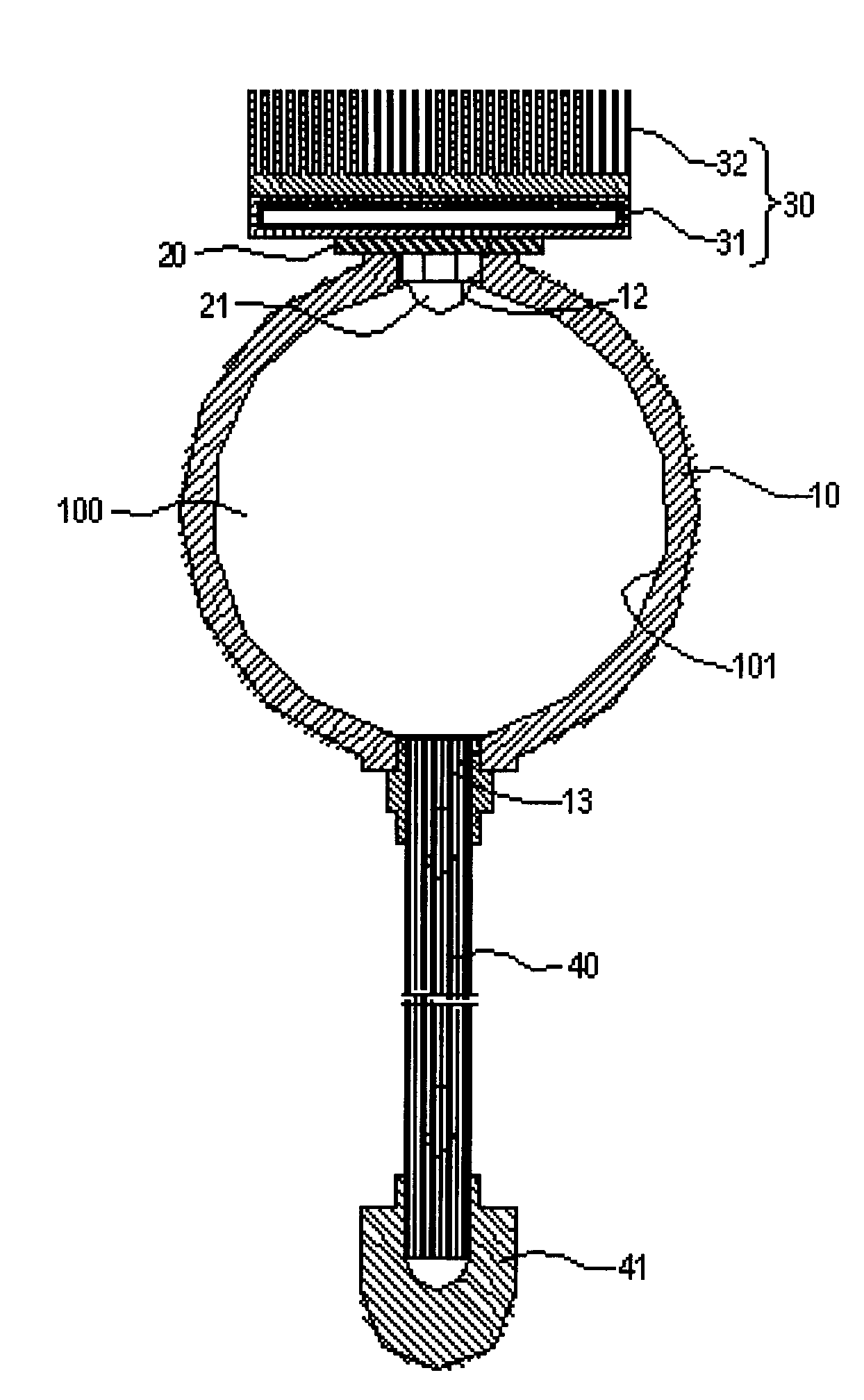

[0047] Please refer to the first figure to the third figure, which are the three-dimensional exploded view, the three-dimensional appearance schematic diagram and the combined cross-sectional view of the LED light guide structure of the present invention; the LED light guide structure of the present invention includes a reflective base 10 and at least one LED light source module 20 , a radiator 30 and an optical fiber tube 40 .

[0048] The reflective base 10 has a hollow chamber 100, the wall of the hollow chamber 100 is shaped without acute angles, so as to increase the number of reflections of light inside the hollow chamber 100 and reduce the loss of light in the process of refraction , in this embodiment, the wall of the hollow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com