Optical film for setting a microlens on upper radial of prism

An optical film and microlens technology, applied in optics, prisms, optical components, etc., can solve the problems of increasing the brightness of the optical axis, increasing the complexity and cost, increasing the installation of related components, volume and cost, etc., to increase the brightness of the optical axis. , the effect of gain light characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

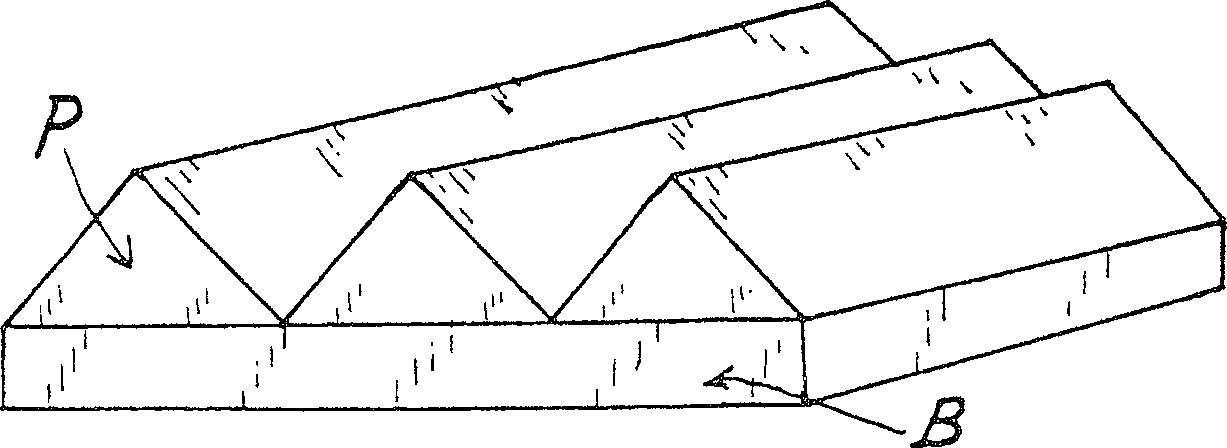

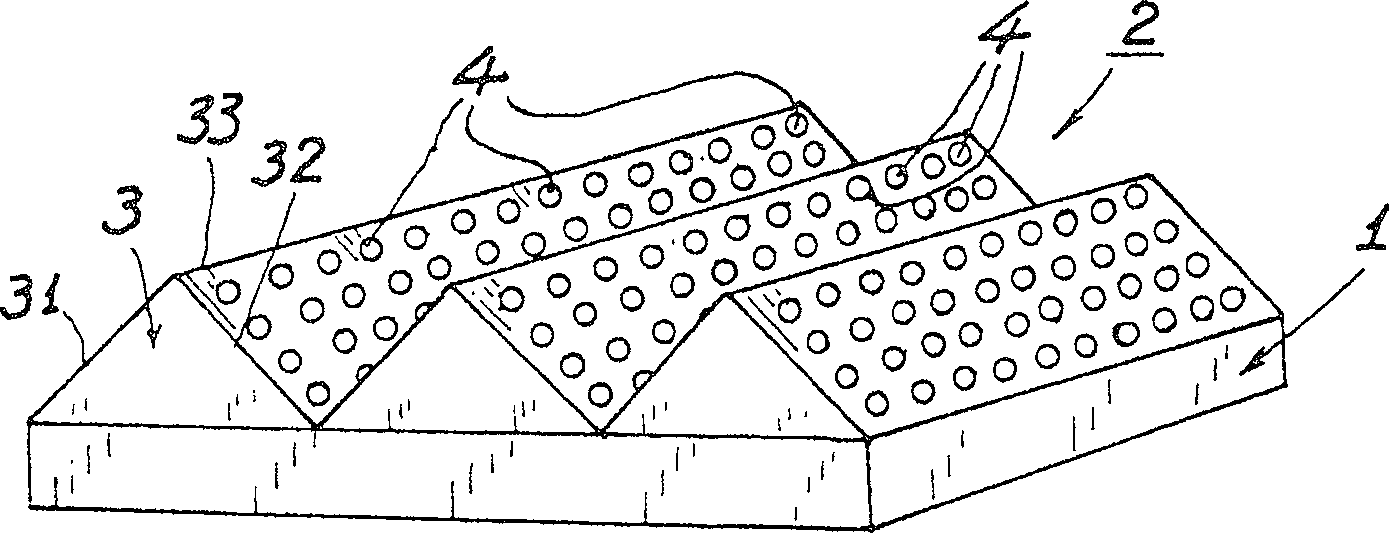

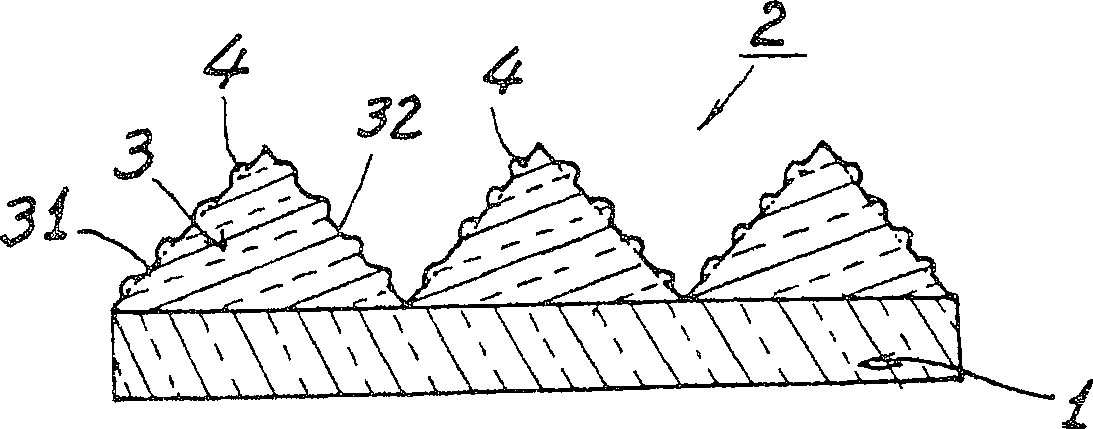

[0026] refer to figure 2 , image 3 , Figure 4 , the optical film of the present invention comprises: a transparent base layer 1; A plurality of micro-lenses 4 (micor-lenses), including convex lenses and concave lenses, are provided continuously or integrally formed.

[0027] The cross-section of each microlens 4 can be in shapes such as arc, crescent, semicircle, and its bottom surface and prism surface 31 or 32 are coplanar (coplanar); Or the bottom surface of 32 takes the inflection point (I, Inflection point) of the microlens as its vertex outwardly in the direction away from the prism surface and gradually convexes (covex).

[0028] The microlens 4 should be integrally formed on the prism surfaces 31, 32 of each prism; and the prism 3 and the microlens 4 can be integrally formed on the base layer 1 by molding or transfer printing. superior.

[0029] The transparent base layer 1 can be made of thermoplastic resins, including polystyrene dicarboxylate (PET), polycarb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com