Light-emitting-diode chip comprising sequence of GAN-based epitaxial layers which emit radiation, and method for producing same

一种发光二极管、外延层的技术,应用在电气元件、电固体器件、电路等方向,能够解决增加制造费用等问题,达到有效冷却、提高波长稳定性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

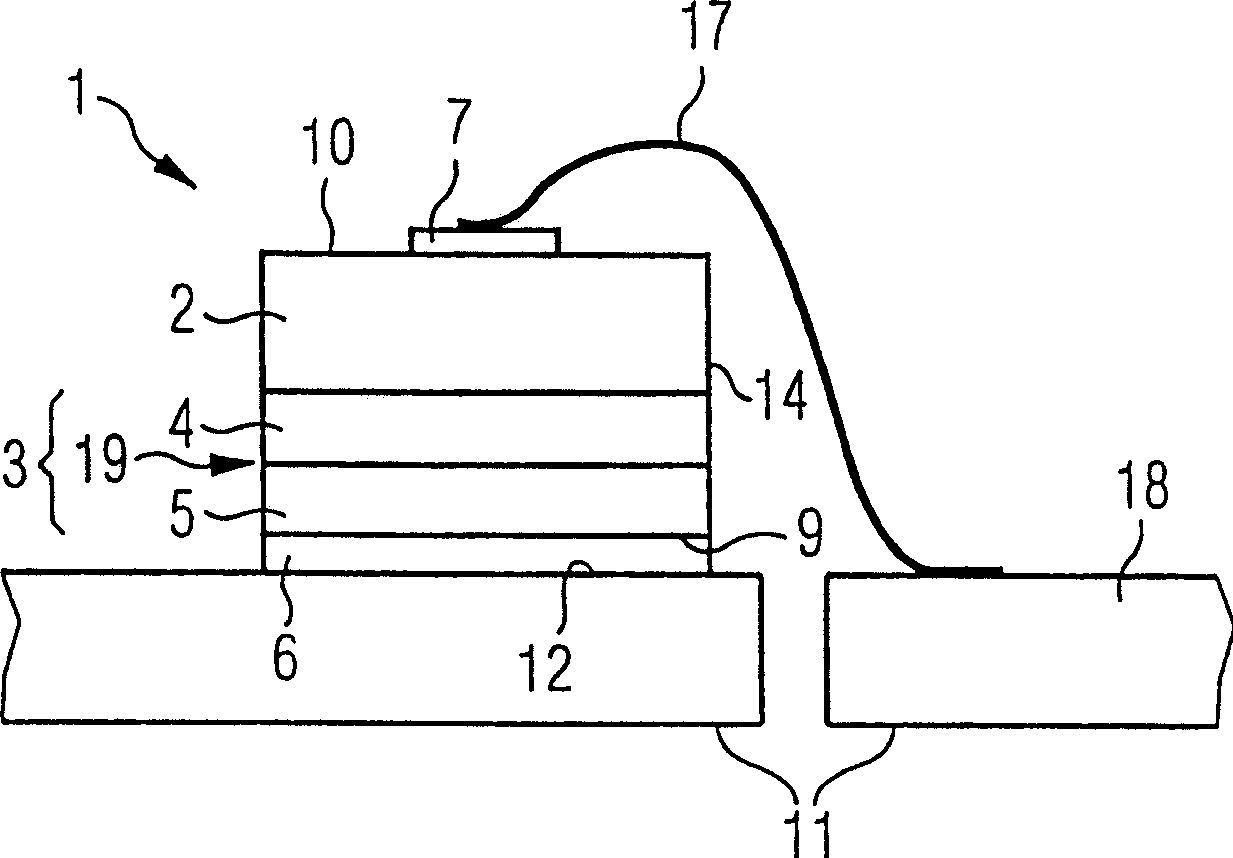

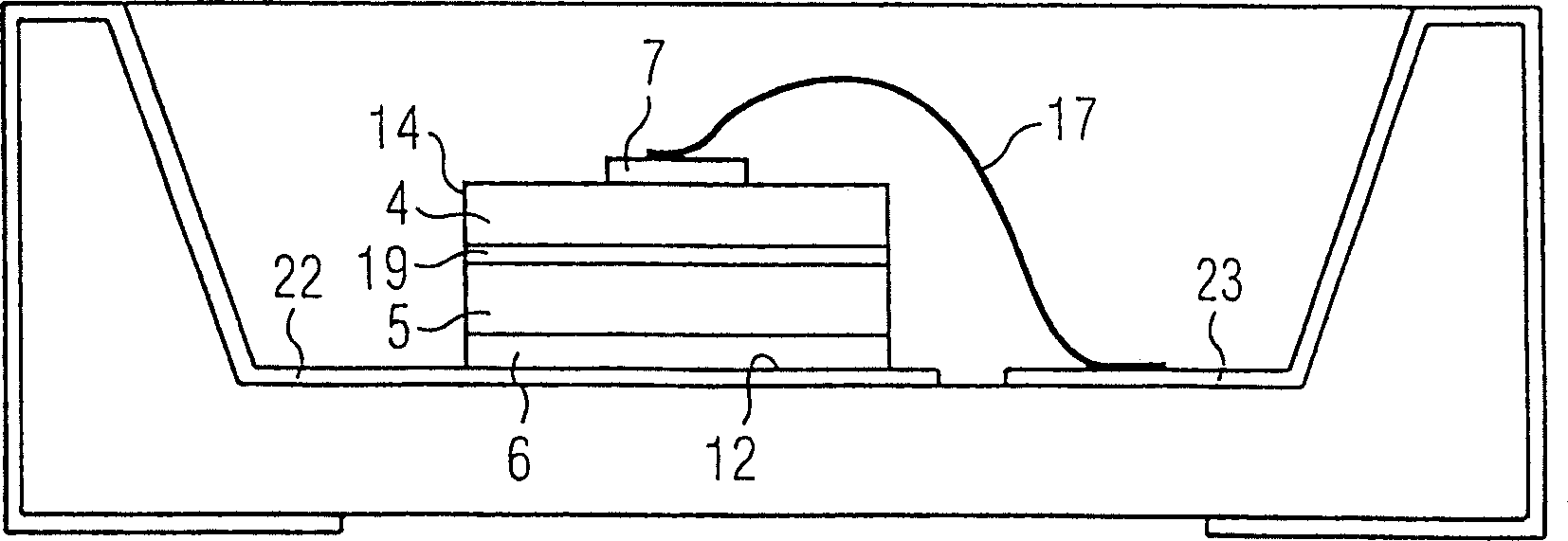

[0039] exist Figure 1a In the light-emitting diode chip 1 , a radiant epitaxial layer sequence 3 is applied on a SiC substrate 2 . The epitaxial layer sequence consists of an n-conductively doped GaN or AlGaN epitaxial layer 4 and a p-conductively doped GaN or AlGaN epitaxial layer 5 . Likewise, it is possible, for example, to set up a GaN-based epitaxial layer sequence 3 with a double heterostructure, a single quantum well (SQW) structure or a multiple quantum well (MQW) structure with one or more An undoped layer 19 composed of InGaAlN.

[0040] Said SiC substrate 2 is electrically conductive and transparent to radiation emanating from the active region 19 of the epitaxial layer sequence 3 .

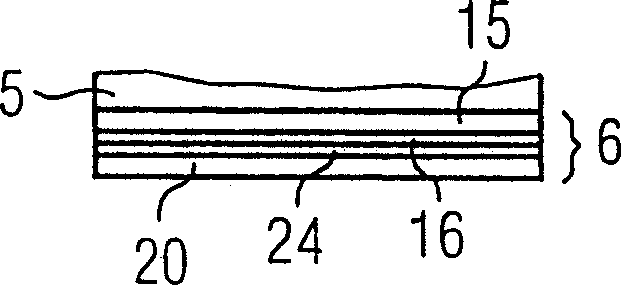

[0041] On its p-side 9 facing away from the SiC substrate 2 , a reflective but solderable Ag-based contact metallization 6 is applied over the entire surface of the epitaxial layer sequence 3 . The metal layer consists, for example, essentially of Ag, PtAg and / or PdAg alloys.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com