Method for hot-rolling a slab and hot-rolling mill

A technology of hot rolling mill and rolling stand, applied in the field of hot rolling slab, which can solve problems such as damage to the characteristics of the final product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

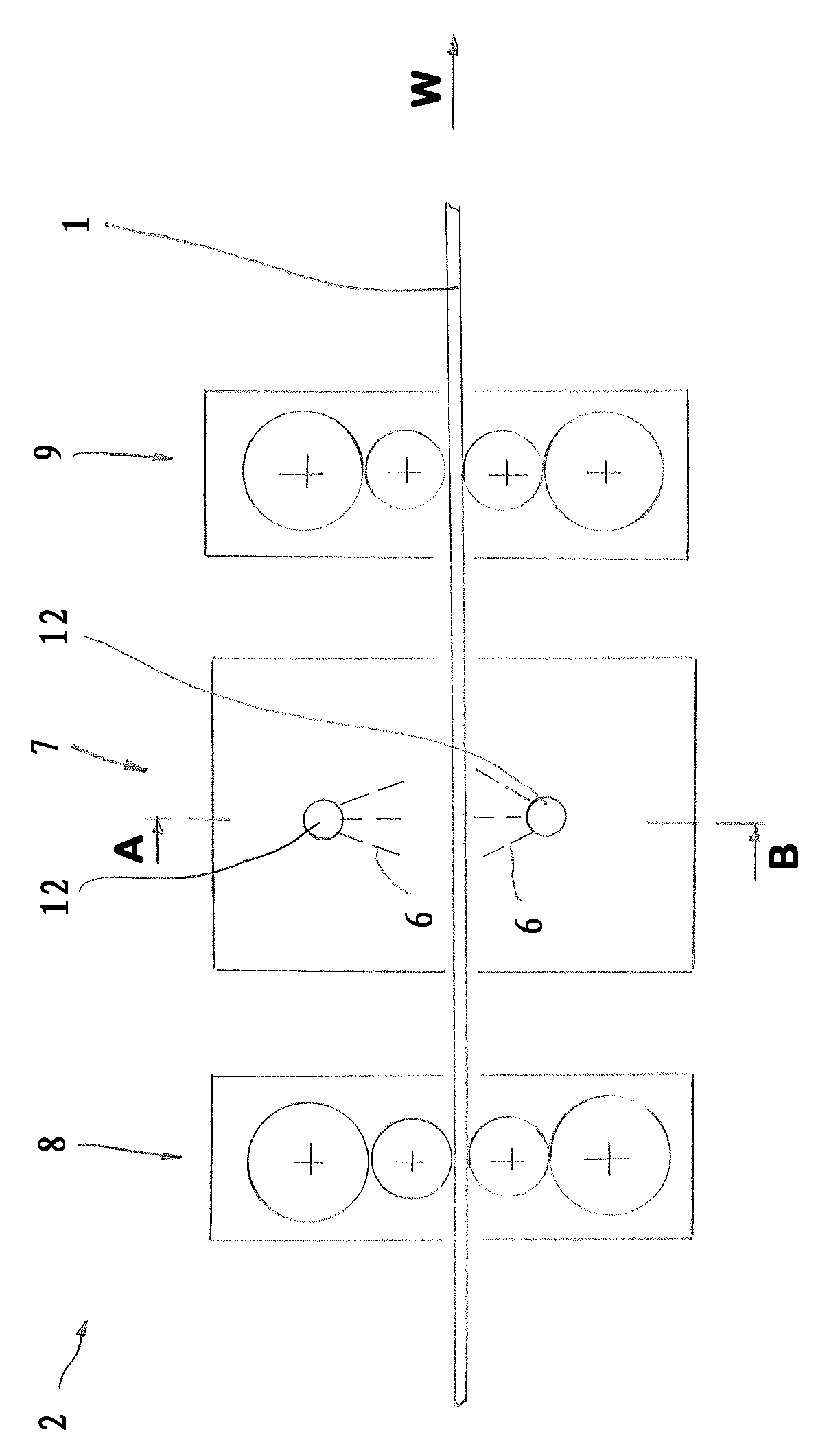

[0024] exist figure 1 A hot rolling mill 2 is depicted in , in which a slab 1 can be rolled. For this purpose, there are several hot rolling stands 8 , 9 , of which only two are shown. During rolling, the slab is conveyed in the rolling direction W and rolled in a known manner. During rolling, the slab is subjected to a thermomechanical treatment.

[0025] Accordingly, the slab 1 is subjected to a thickness reduction in the first hot rolling stand 8 . The slab 1 is cooled after the stand 8 , for which the slab 1 is guided through a cooling station 7 , which is formed here as an intermediate cooling stand.

[0026] After the cooling station 7 , the slab 1 is now re-rolled in the hot rolling stand 9 , in particular at a lower temperature than in the hot rolling stand 8 .

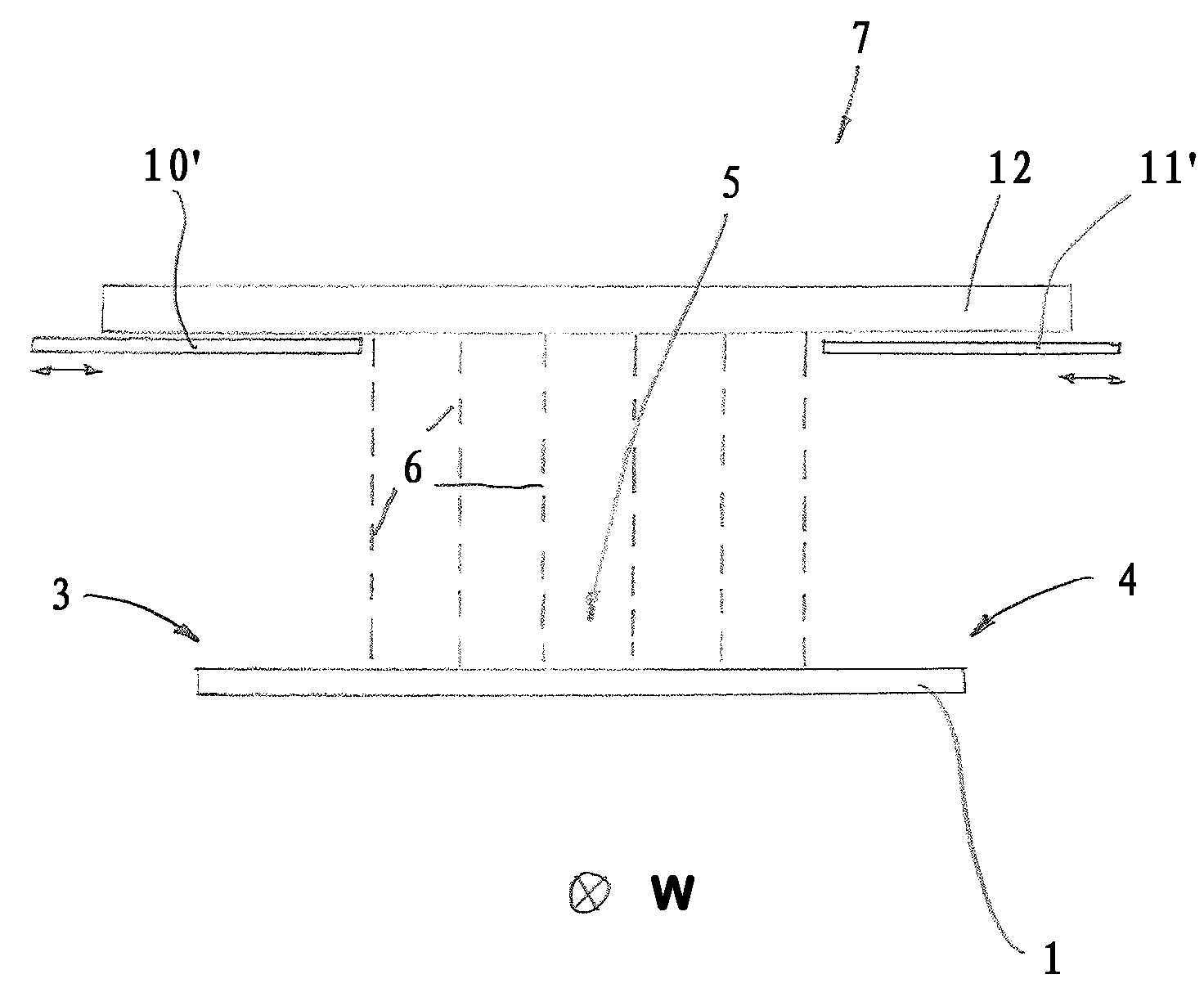

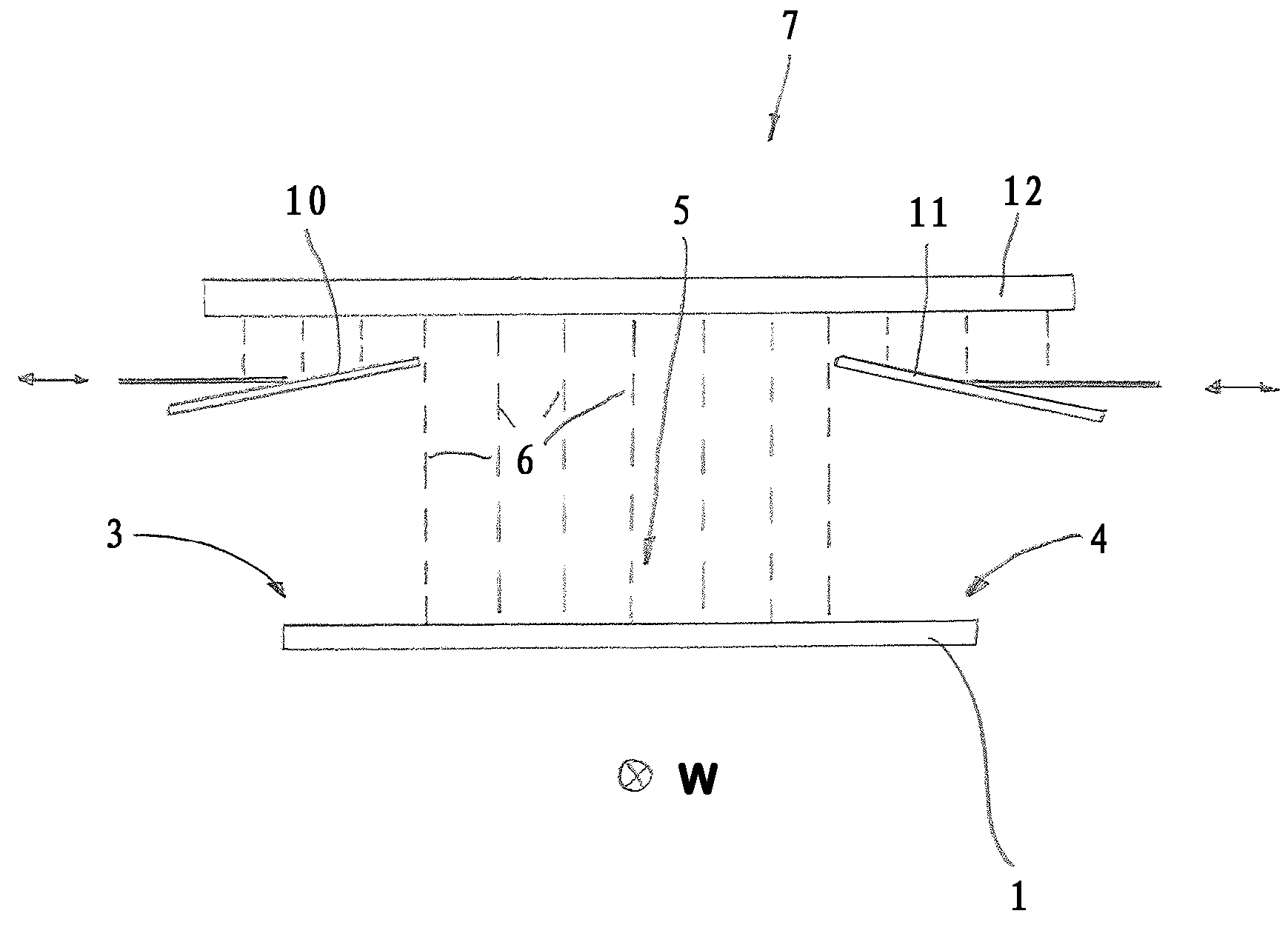

[0027] Cooling of the slab 1 takes place in the cooling station 7 by spraying a cooling medium 6 , here in the form of water. For this purpose there is the known chilled beam 12 .

[0028] from figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com