Motor control system for a hoist drive

一种控制系统、电动机的技术,应用在交流电动机控制、控制系统、单个电动机转速/转矩控制等方向,能够解决负载重量传感器昂贵等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

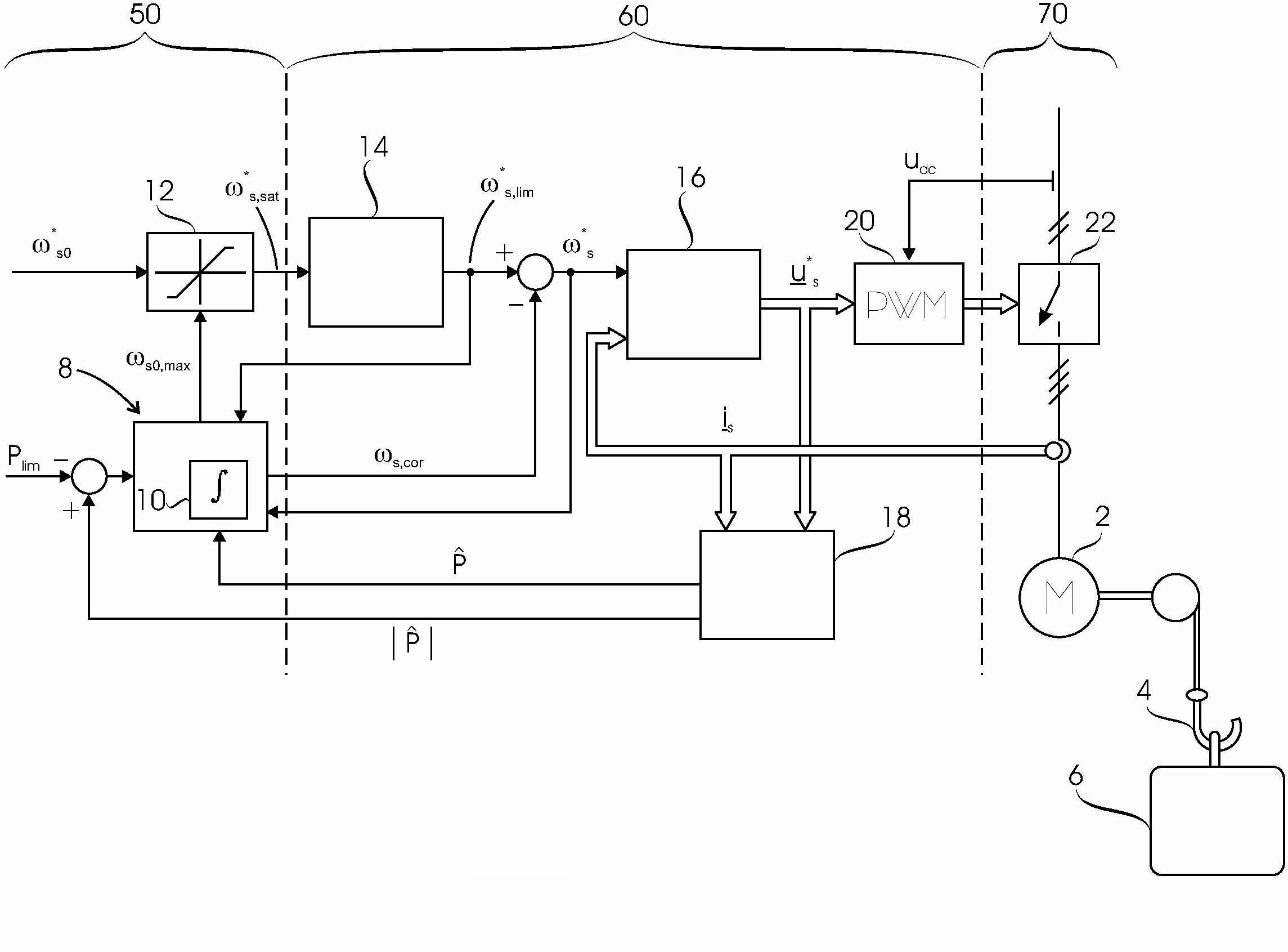

[0012] figure 1 An open loop crane drive is shown comprising an electric motor 2 operatively connected to a lifting member 4 for lifting a load 6 . The electric motor 2 is controlled by a motor control system according to an embodiment of the present invention. The motor control system comprises power limiter means 8 , saturation means 12 , rate limiter means 14 , control means 16 , power estimator means 18 and pulse width modulation means 20 . The motor control system is adapted to generate a final angular frequency reference ω for controlling the motor 2 based on the initial data * s , the initial data includes a constrained setpoint value ω for the angular frequency reference * s,lim and the correction term ω for the angular frequency reference s,cor . exist figure 1 In the open-loop embodiment of , the final angular frequency reference ω * s is the synchronous angular frequency reference, and the control device 16 is a scalar control device.

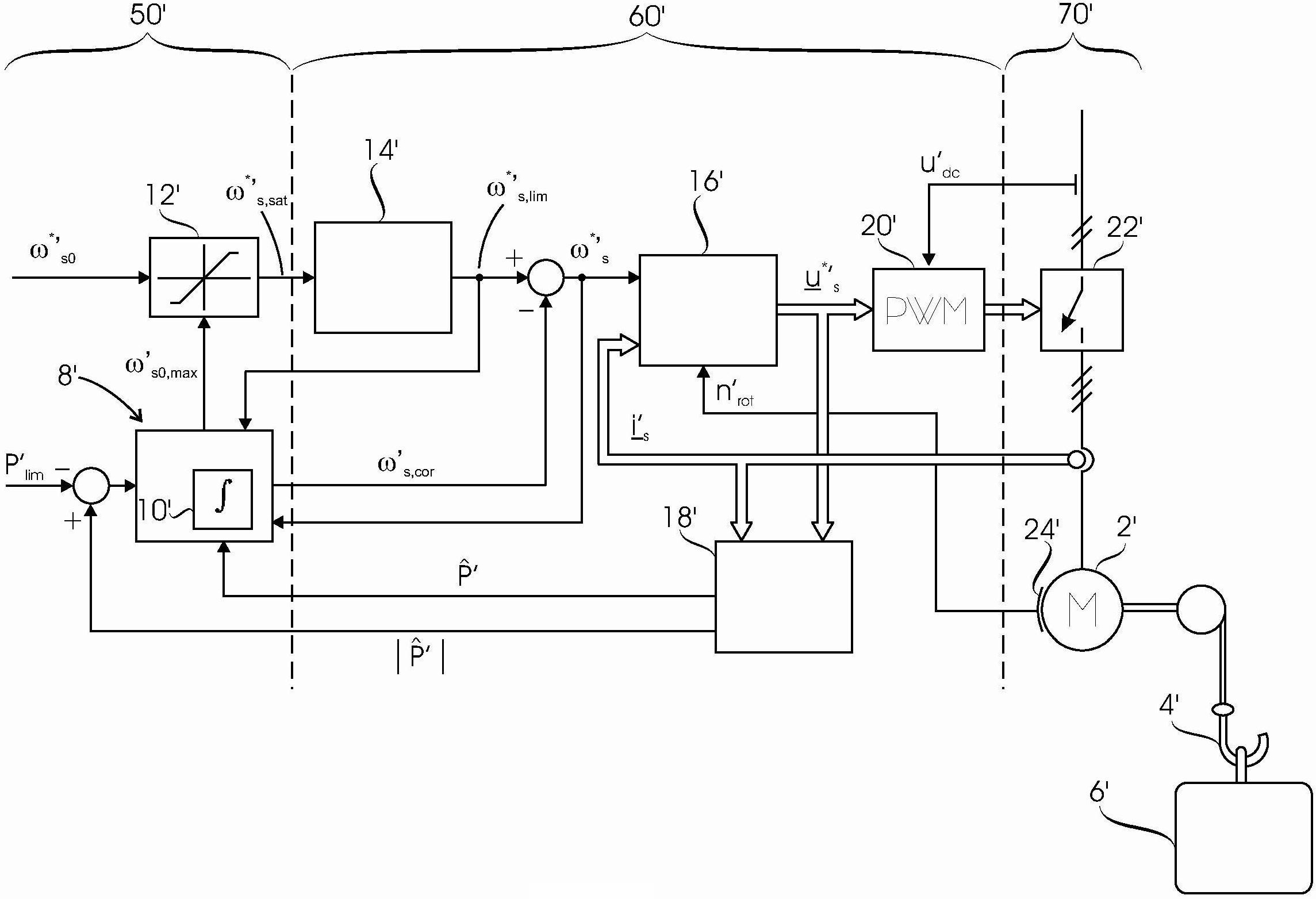

[0013] exist figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com