Axial flux induction electric machine

An induction motor, axial magnetic flux technology, applied in asynchronous induction motors, electromechanical devices, electrical components, etc., can solve the problems of low rotation speed and low durability, and achieve the effect of high rotation speed and easy manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

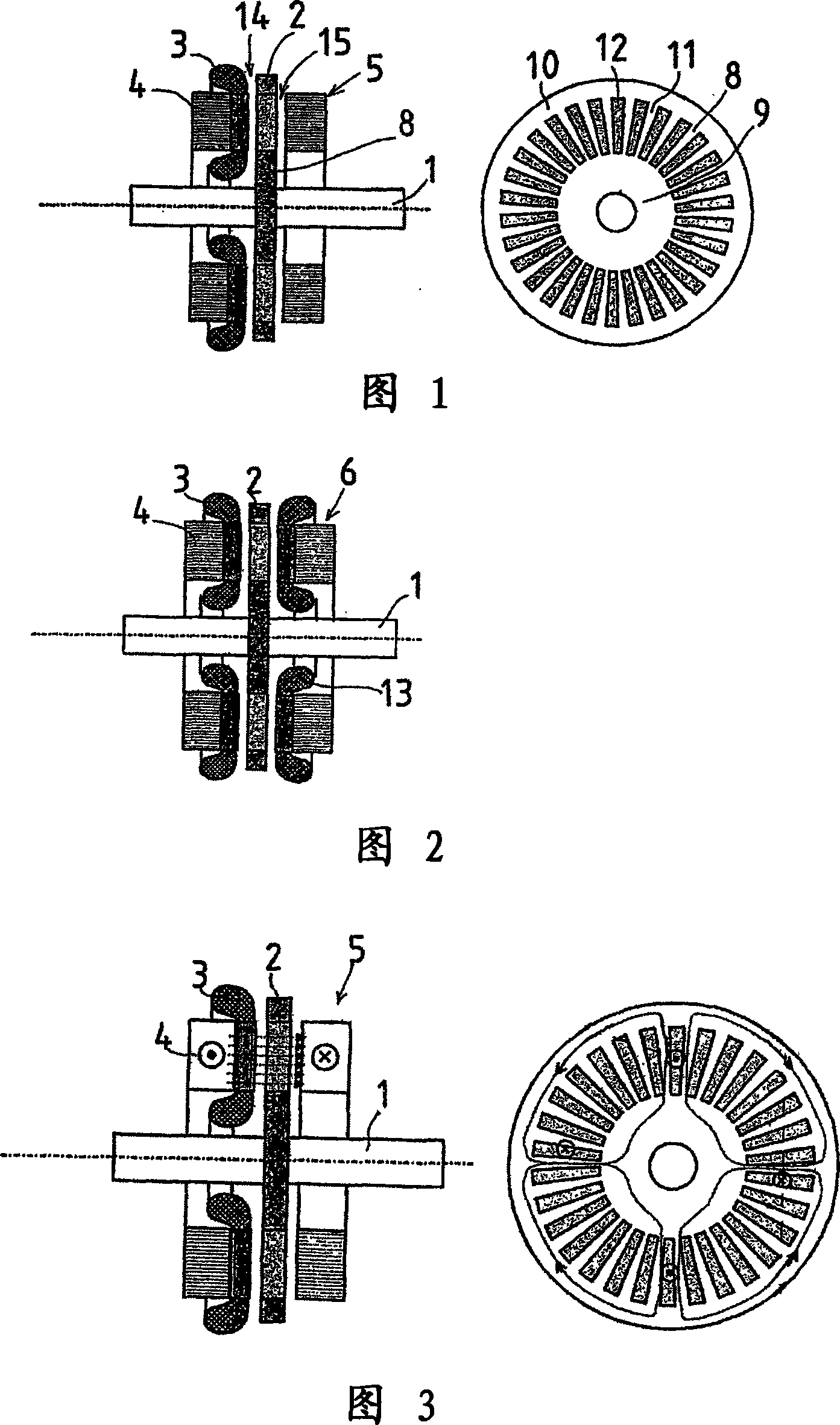

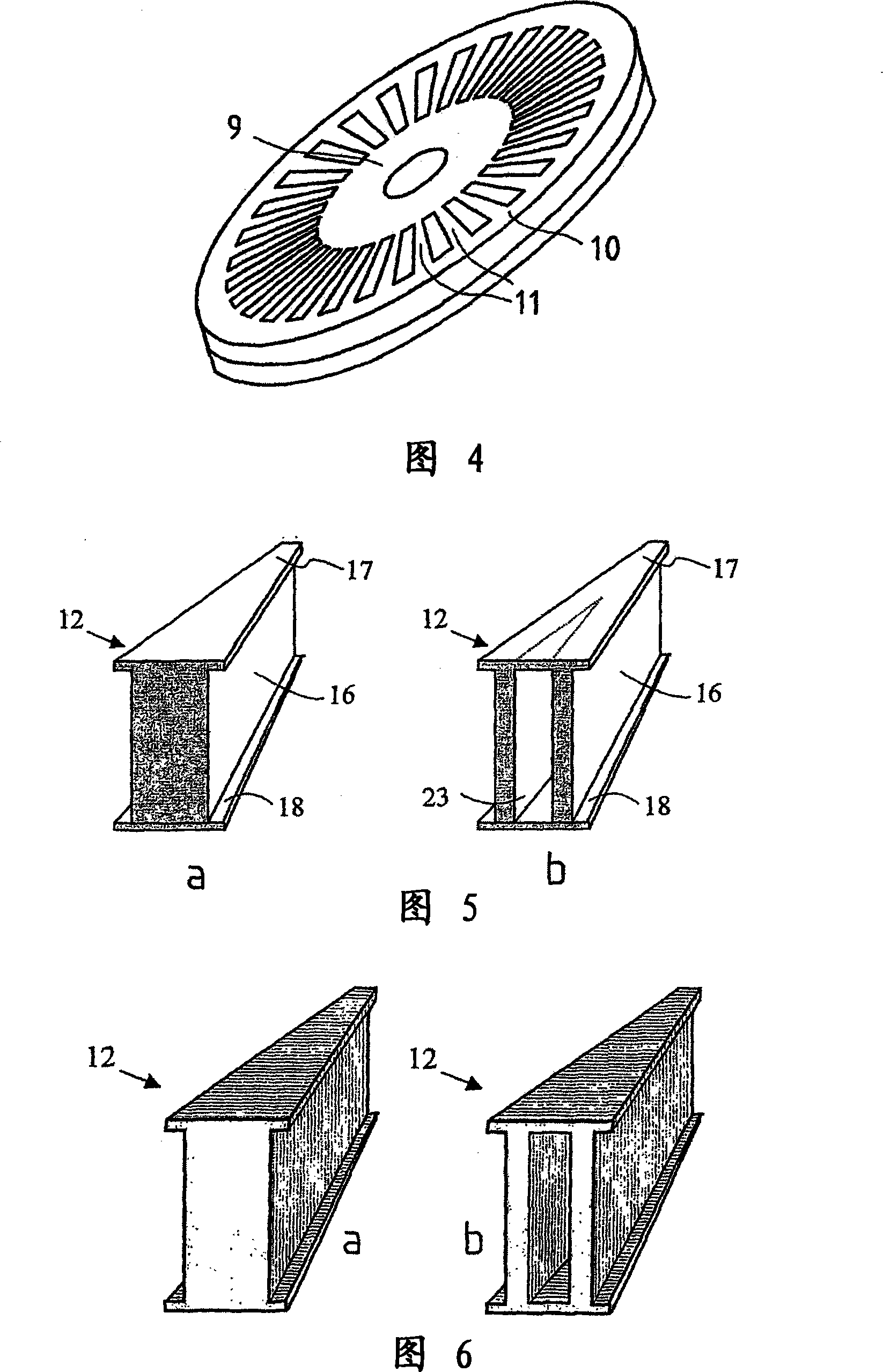

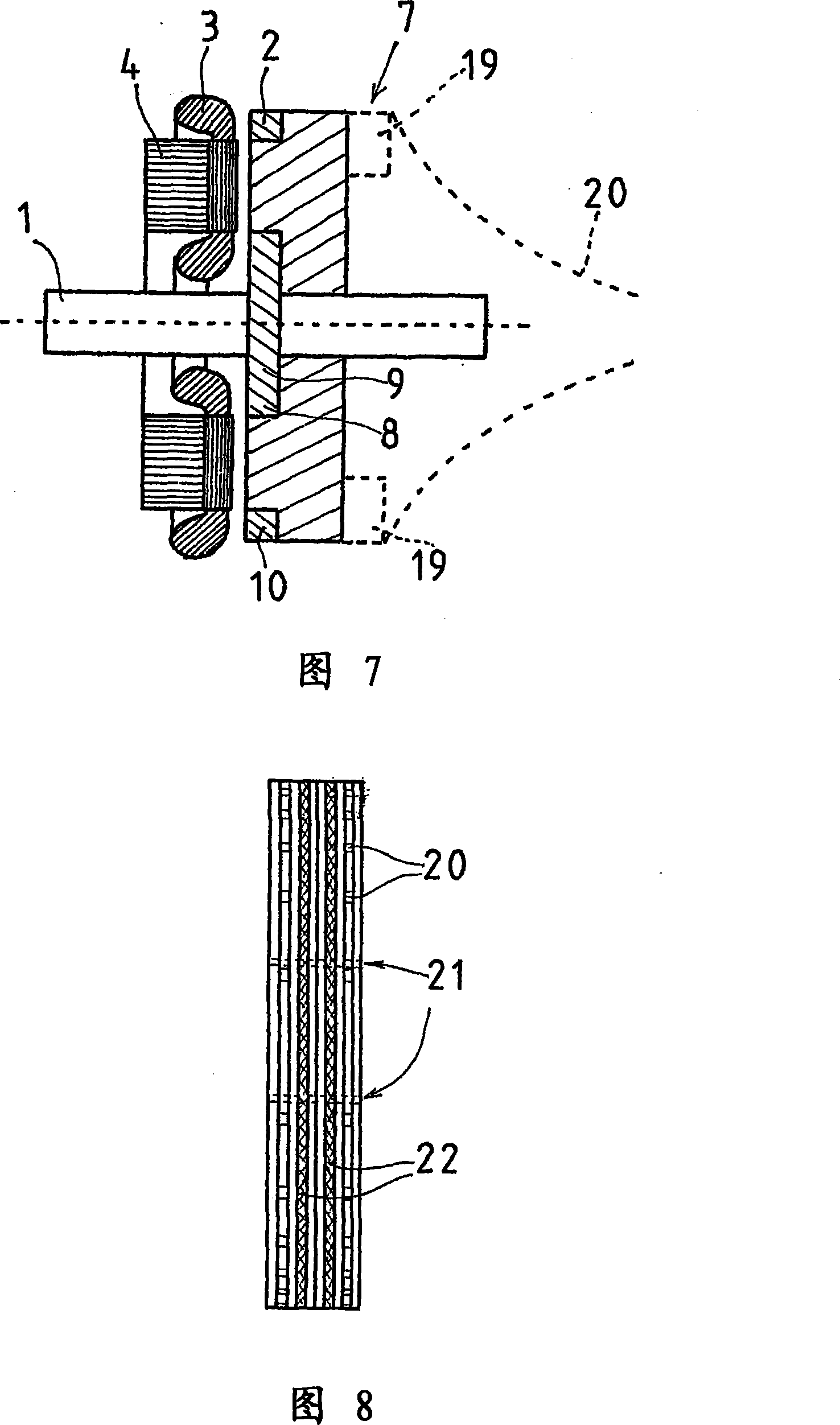

[0031] Fig. 1 shows a motor of the present invention, in which a shaft 1 rotating about a frame of the motor and a disc rotor 2 supported to the shaft are arranged, while viewing the rotor from the side. A stator 4 supported to the motor frame is arranged in the direction of the shaft 1 on the first side of the rotor 2 and includes a stator winding 3 . Between the rotor 2 and the stator 4 there is a small air gap 14, behind a corresponding air gap 15 on the other side of the rotor, the assembly conducting the magnetic flux is arranged, which in this embodiment is the rotor fixed relative to the frame Yoke 5. The rotor yoke 5 can be made of a suitable composite material, or it can be a helical laminate made of electrical steel sheets. The rotor frame plates 8 are made of work hardened rolled plate of a suitable aluminum or copper alloy.

[0032]In the second embodiment of FIG. 2 , the rotor 2 and the stator 4 are similar to the embodiment of FIG. 1 . Alternatively, the magne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com