Canning water control machine

A water machine and canning technology, which is applied in the field of canned water control machines, can solve the problems of slow speed and inconvenient adjustment of various tank types, and achieve the effects of simple and convenient operation, labor cost saving, and complete control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

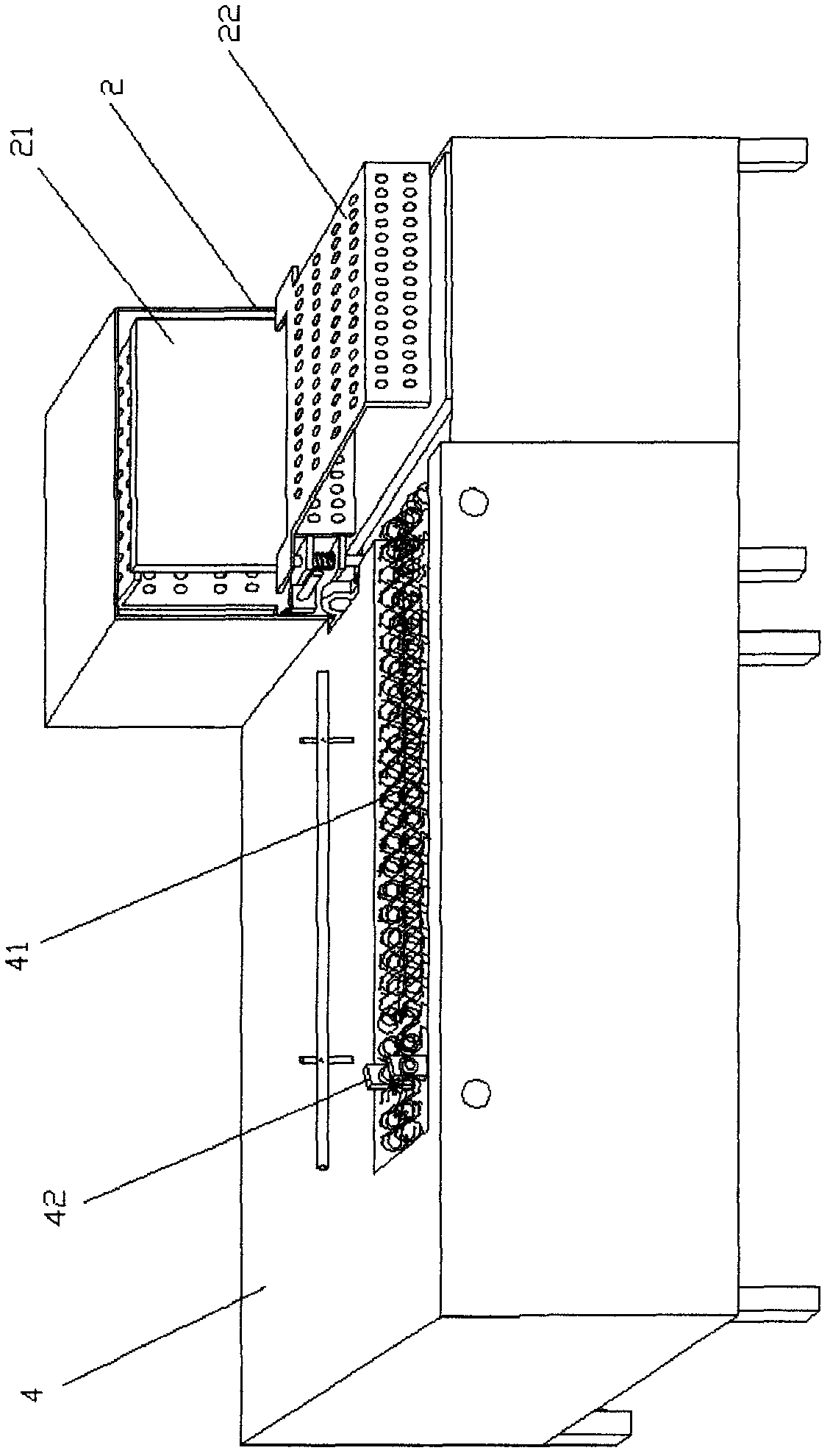

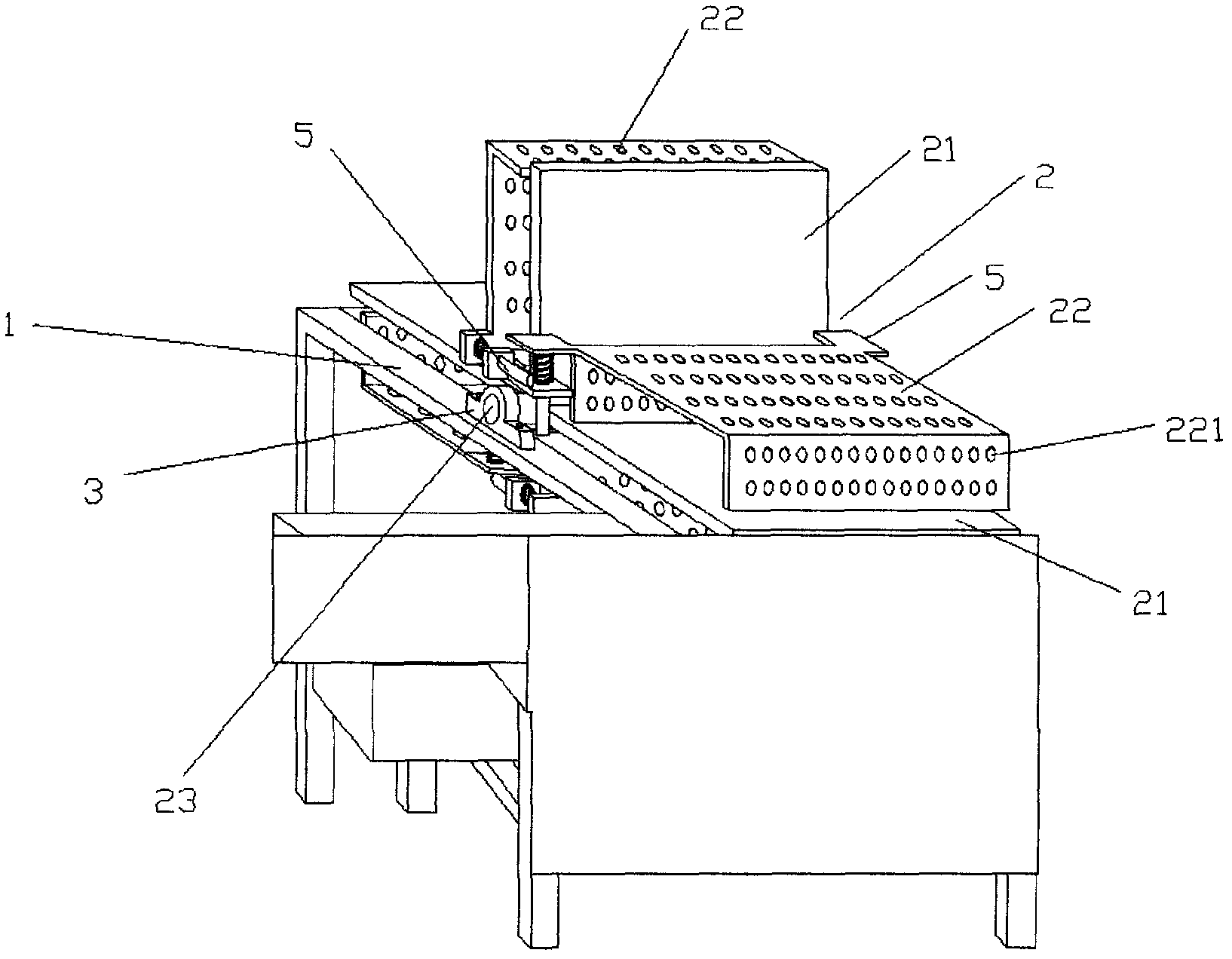

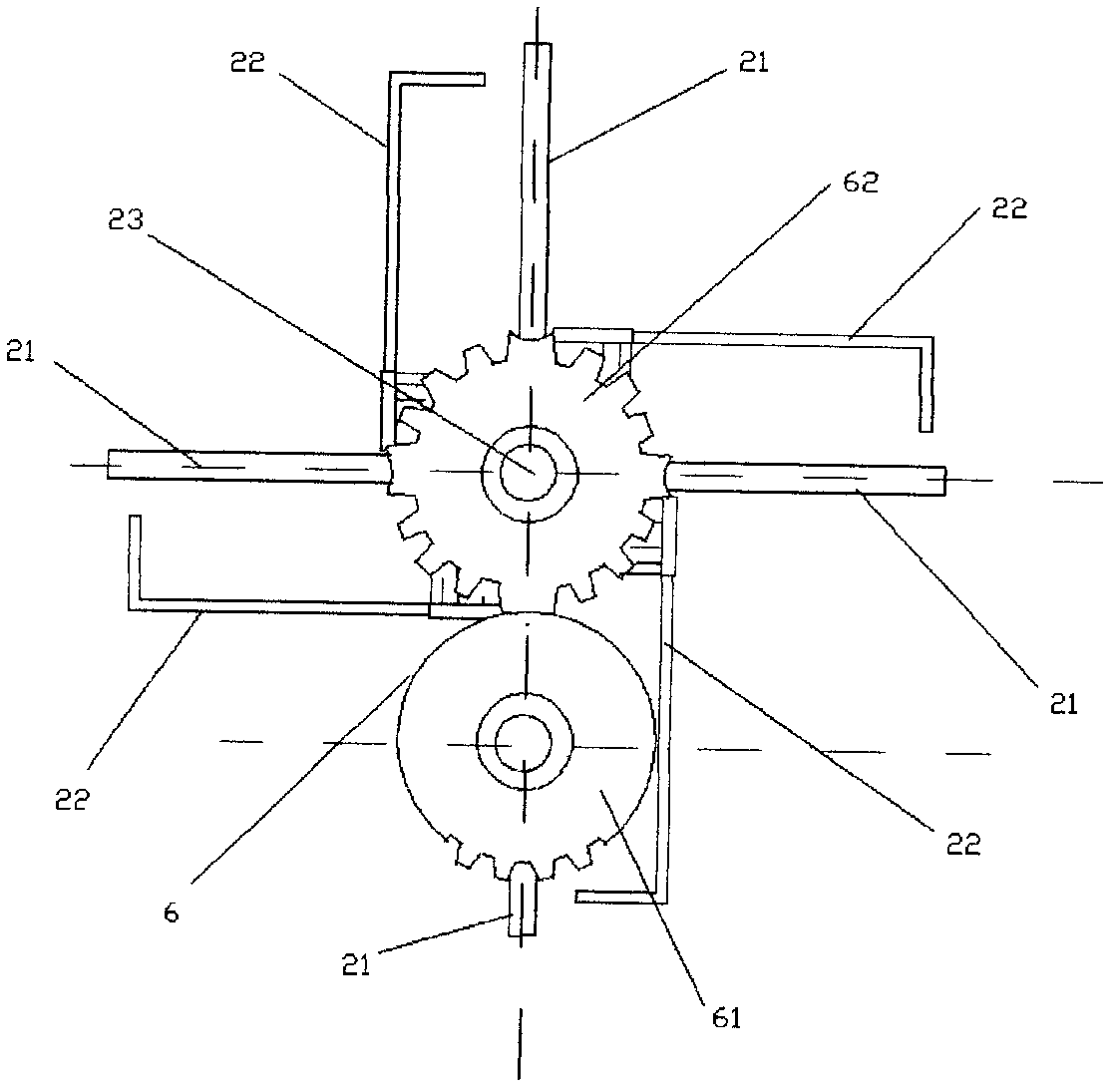

[0019] Such as figure 1 , 2 As shown, a canned water control machine includes a frame 1, a transmission mechanism, a draining device 2, and a delivery platform 4. The two ends of the rotating shaft 23 of the draining device 2 are installed on the frame 1 through the bearing housing 3, and the rotating shaft 23 is fixed in the axial direction with a rotating plate 21, and the surface of the rotating plate 21 is provided with a drain cover 22, the drain cover 22 is bent from a stainless steel plate, and its cross section is in the shape of "∏". There are holes 221, and the holes 221 allow the water in the empty tank to be discharged. The size of the drain cover 22 matches the tray containing the empty tank with the contents. The two ends of the drain cover 22 are provided with a holding device that can move the drain cover up and down. An adjustment mechanism 5, the pressing adjustment mechanism 5 includes a drain cover support 51 and a cam pusher 52, the movable rod 511 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com