Canning automatic water control machine

An automatic and water machine technology, applied in the direction of packaging, etc., to achieve the effect of complete control, labor cost saving, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

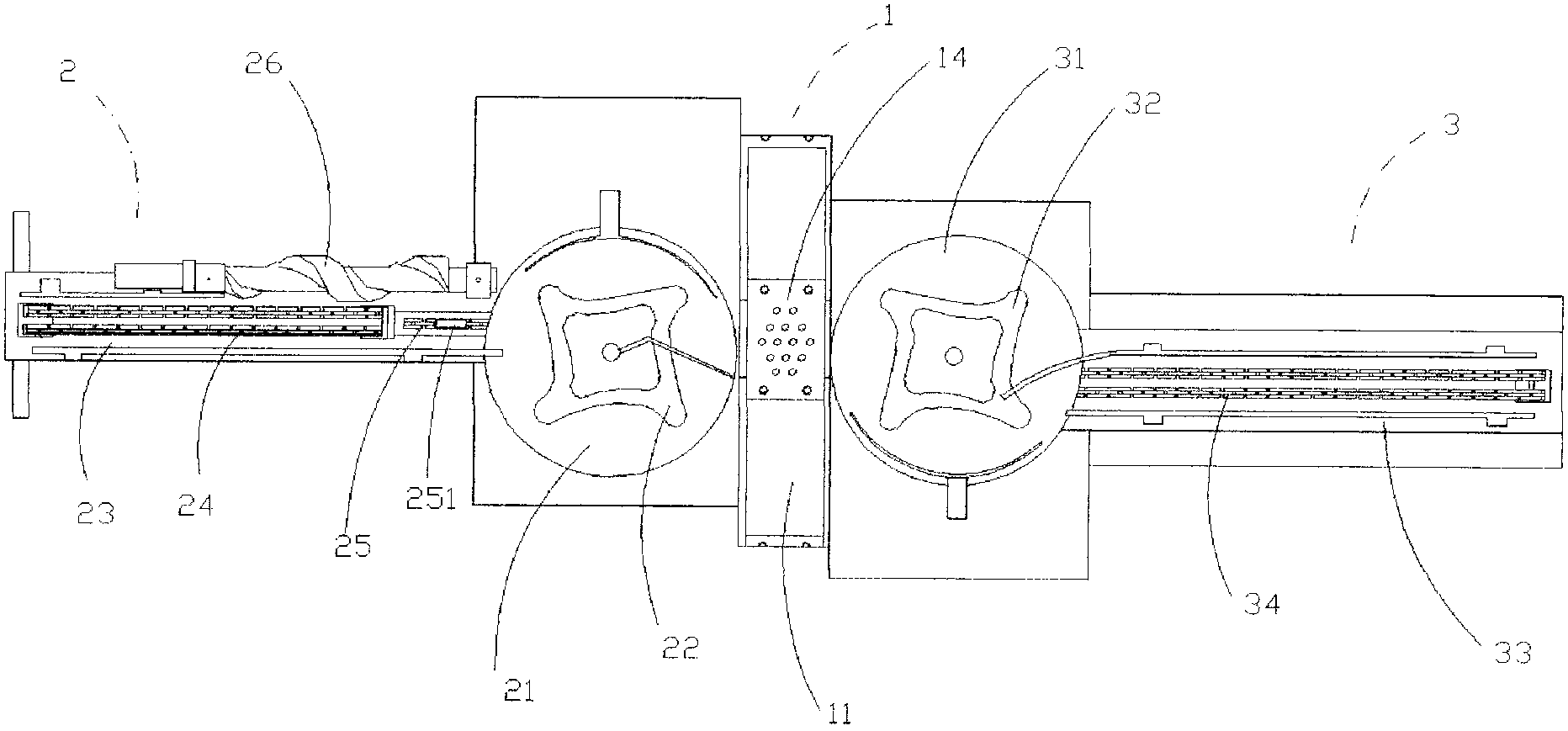

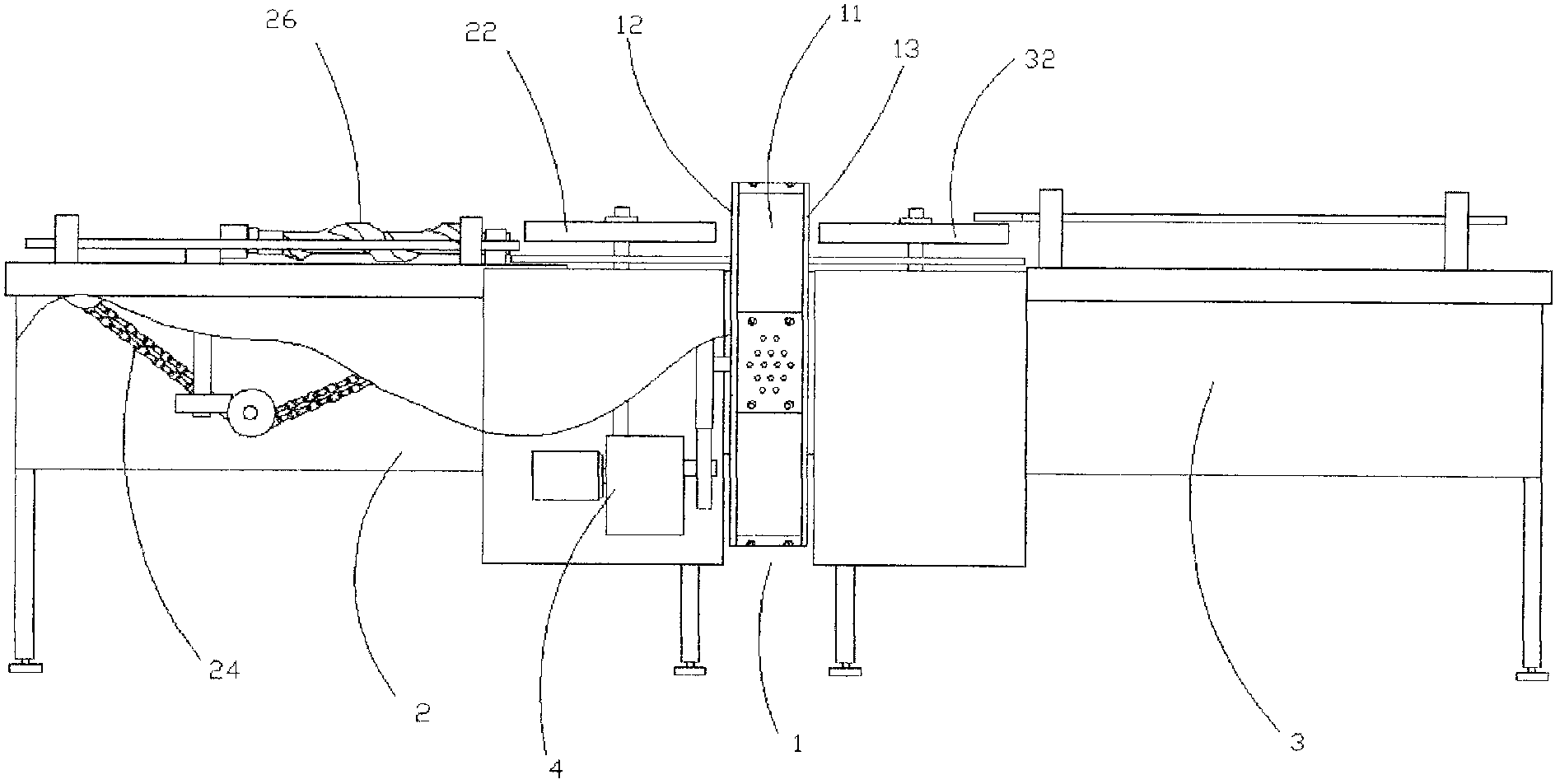

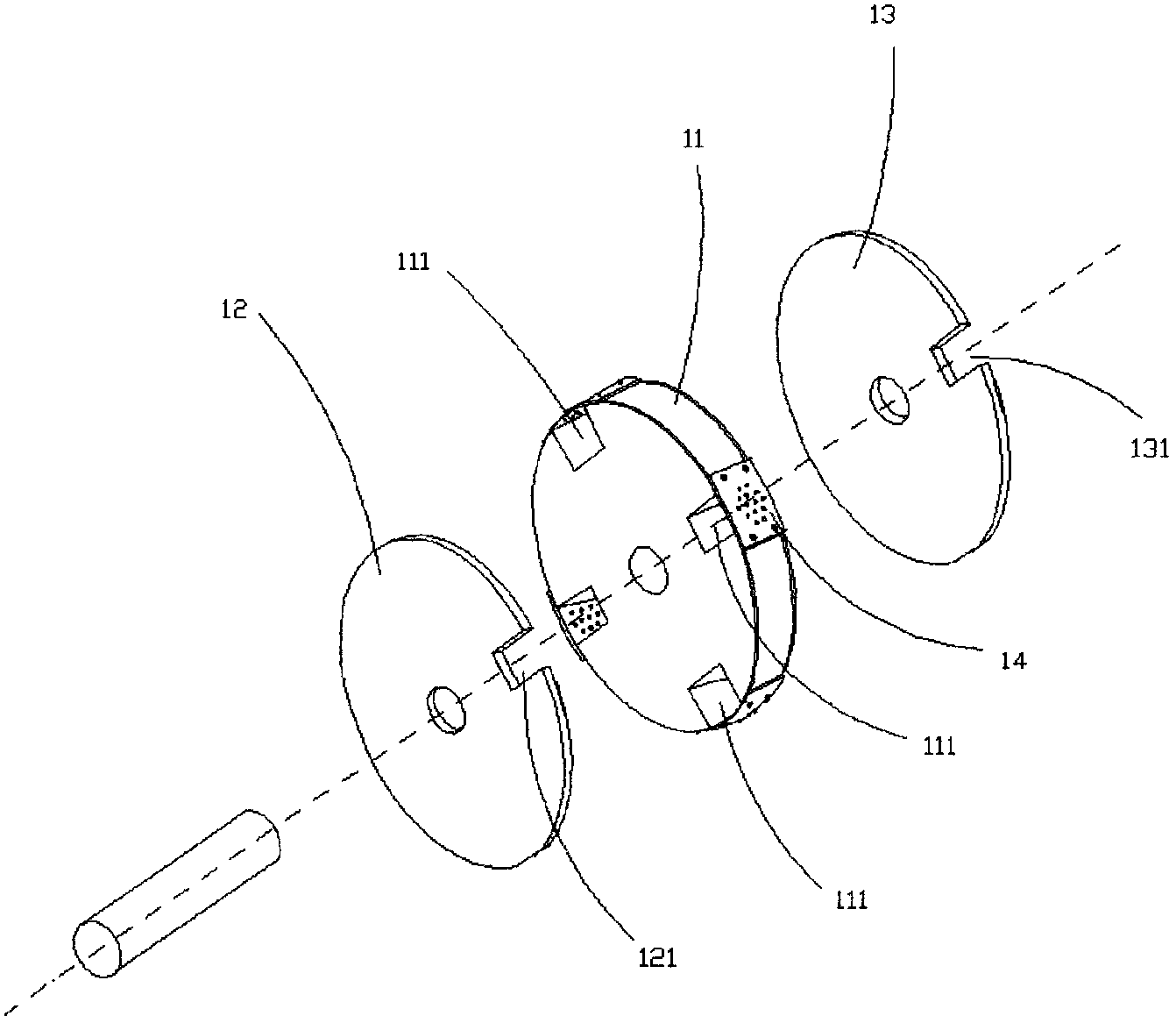

[0019] Such as Figure 1-5 As shown, an automatic water control machine for tank storage includes a water draining device 1, an input mechanism 2, an output mechanism 3, and a transmission mechanism 4. In operation, the transmission mechanism is composed of a motor, a gearbox, a rotating shaft and a gear connection, which drives the draining device, the input mechanism and the output mechanism to rotate synchronously. The draining device 1 is composed of a draining turntable 11 coaxially combined with a left baffle plate 12 and a right baffle plate 13. The draining turntable 11 is provided with one or more equally arranged tank tanks 111, and the tank tanks 111 are used for Place the tank body 5 that needs to be drained, and four tank tanks are drawn in the figure of the present embodiment, and the top of the tank tank is provided with a drain net 14. The left baffle plate 12 is connected to the input mechanism 2, and the edge of the can feeding flat plate 21 of the input mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com