Air cushion type tunnel conveyer

A conveyor and air-cushion technology, applied in the field of air-cushion tunnel conveyors and material conveying devices, can solve the problems of limited conveying materials, easy deviation of materials, pollution of the environment, etc., and achieve the effect of small conveying resistance and energy saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

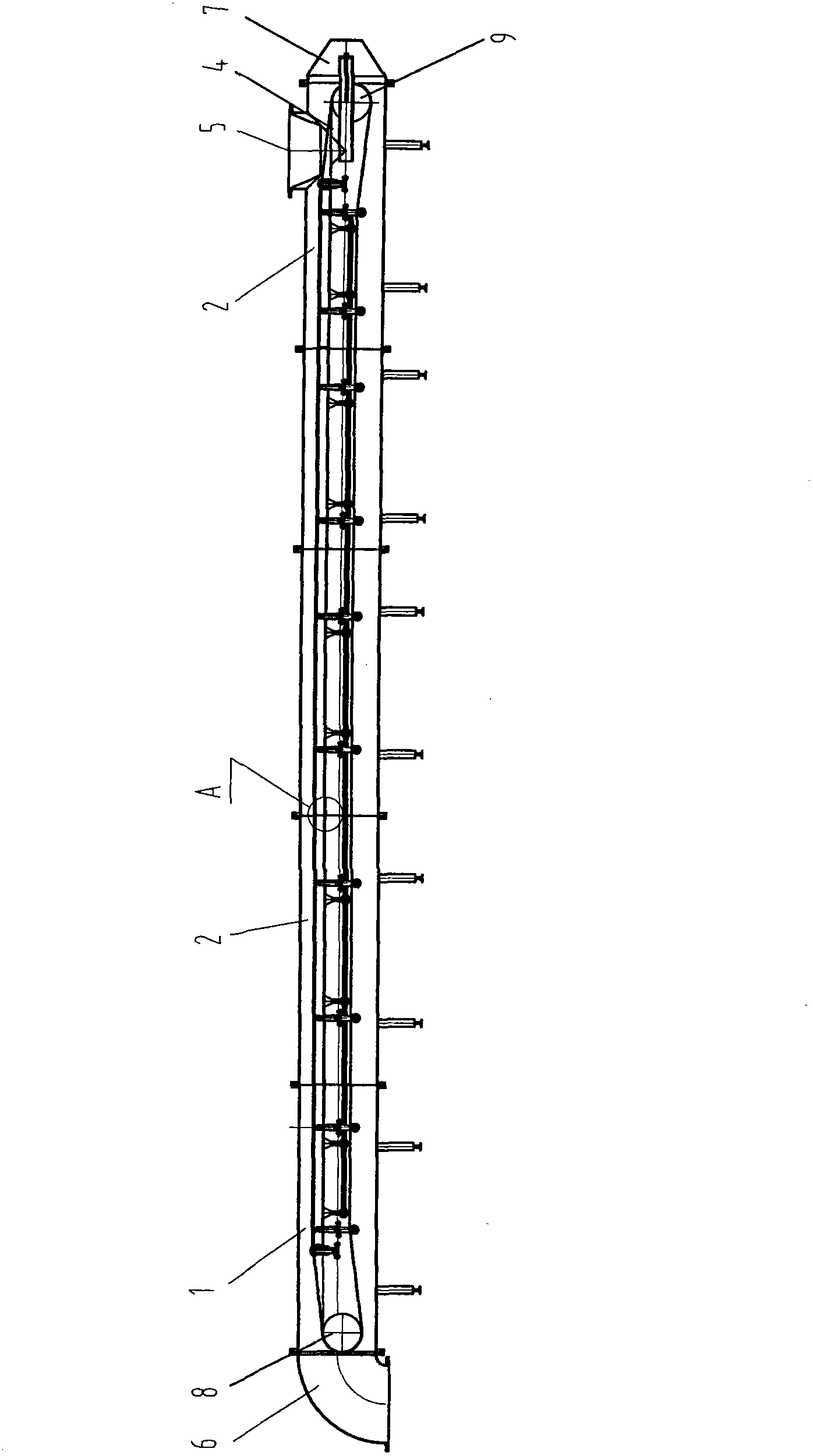

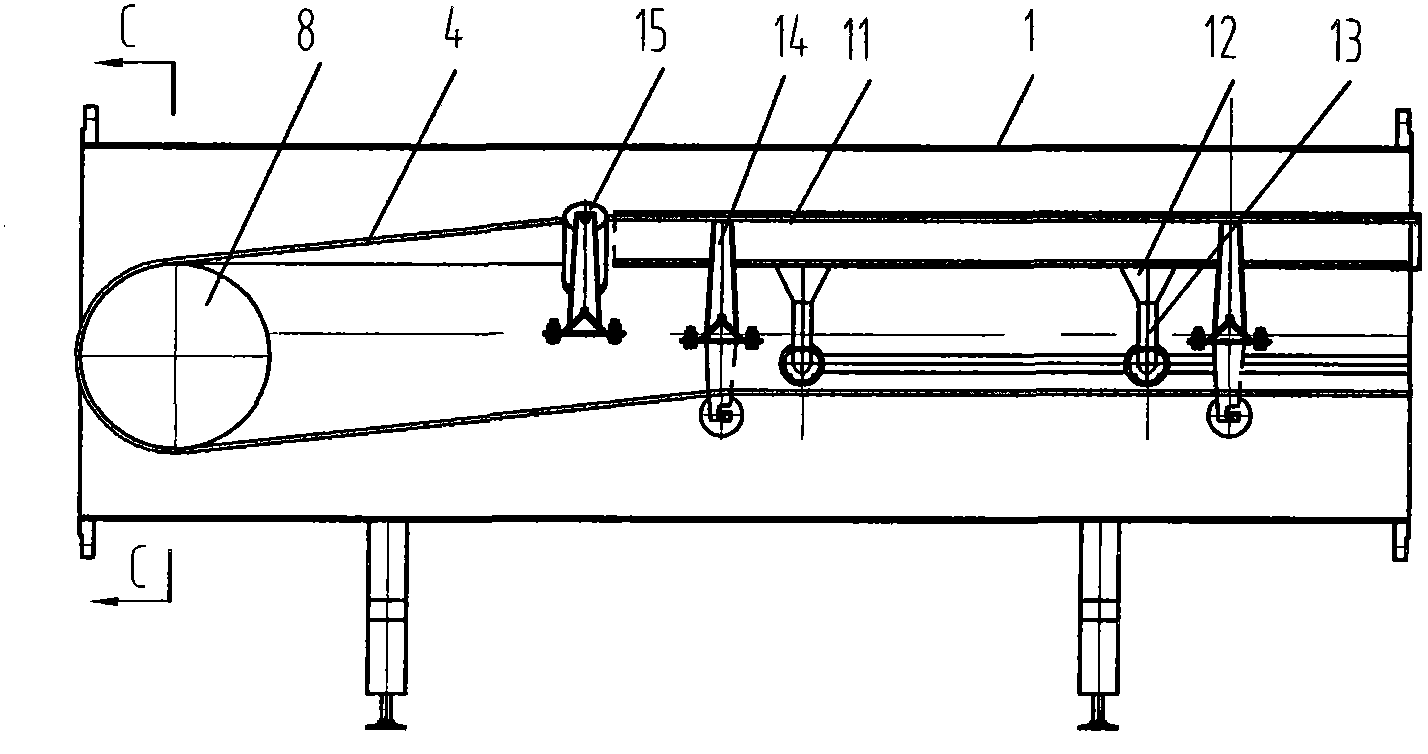

[0019] The basic structure of the air cushion tunnel conveyor in this implementation is as follows: figure 1 As shown, the conveying pipeline with a circular cross section is supported on the column bases distributed at intervals, and is composed of a head section 1 connected to the discharge elbow 6, a number of standard sections 2, and a tail section 3 connected to the tail casing 7. The loop conveyor belt 4 surrounding the built-in driving drum 8 and the reversing drum 9 is installed in the conveying pipeline. The driving drum 8 is connected with the motor speed reducer as the conveying driving device outside the head section. The upper part of the tail section 3 has a funnel-shaped feed opening 5 .

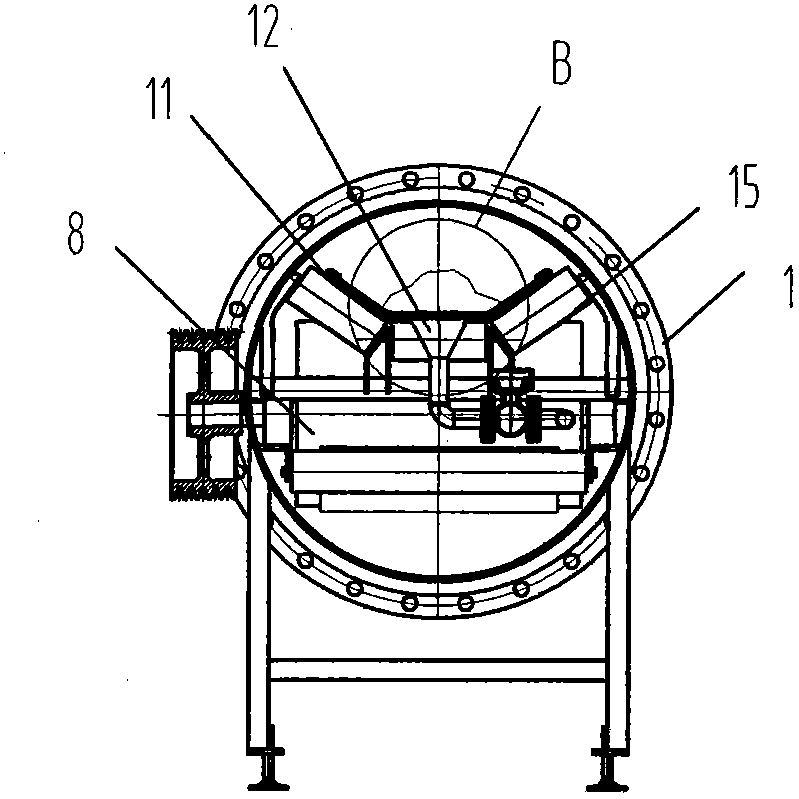

[0020] like Figure 8 As shown, the upper part of the loop conveyor belt 4 is placed on the bracket 11 supported on the conveying pipeline. The cross-section of the bracket is flat-bottomed V-shaped, and the two sides of the notch are respectively formed with hook buckle ed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com