Anti-temper release device

A technology of anti-tempering and cooling device, used in fire rescue, pipes/pipe joints/fittings, mechanical equipment, etc., can solve problems such as accidents, flame arrester failure, etc., to ensure the effect of fire resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with embodiment the present invention is described in further detail, but structure of the present invention is not limited to following embodiment:

[0015] 【Example】

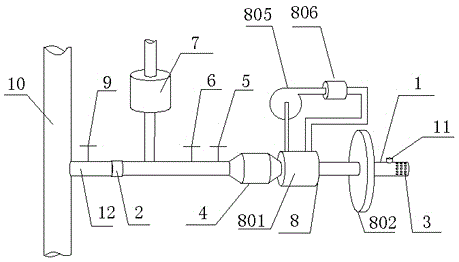

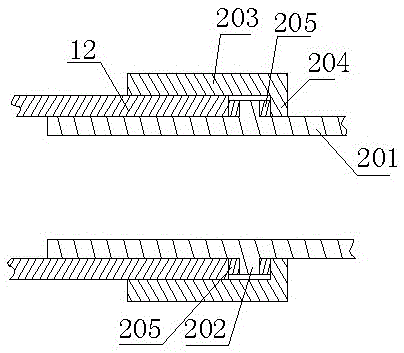

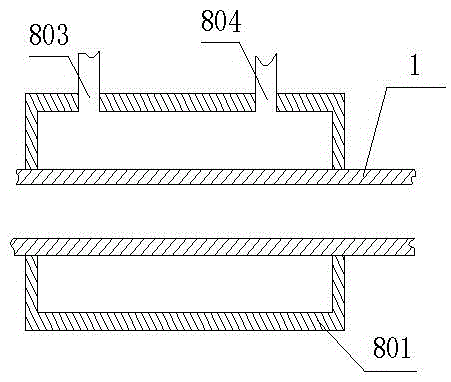

[0016] Such as Figure 1-3 As shown, the anti-backfire release device includes a release pipe 1, one end of the release pipe 1 is a connector 2, and the other end is a combustion head 3, and the connector 2 includes a connecting pipe 201 communicating with the release pipe 1, and the connection pipe 201 The middle section is provided with an annular protrusion 202, and a threaded pipe 203 is also sleeved on the connecting pipe 201. The outer diameter of the threaded pipe 203 is larger than the outer diameter of the annular protrusion 202, and one end of the threaded pipe 203 is provided with a blocking ring 204, the blocking ring The inner diameter of 204 is consistent with the outer diameter of the connecting pipe 201, and a rubber ring 205 is respectively arranged on both sides o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com