Automatic welding root and welding pipe orifice windproof device for long oil and gas conveying pipeline

A windproof device, oil and gas transportation technology, applied in the direction of auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of delay in welding progress, decrease in connection effect, decrease in welding effect, etc., and achieve the effect of saving deployment time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

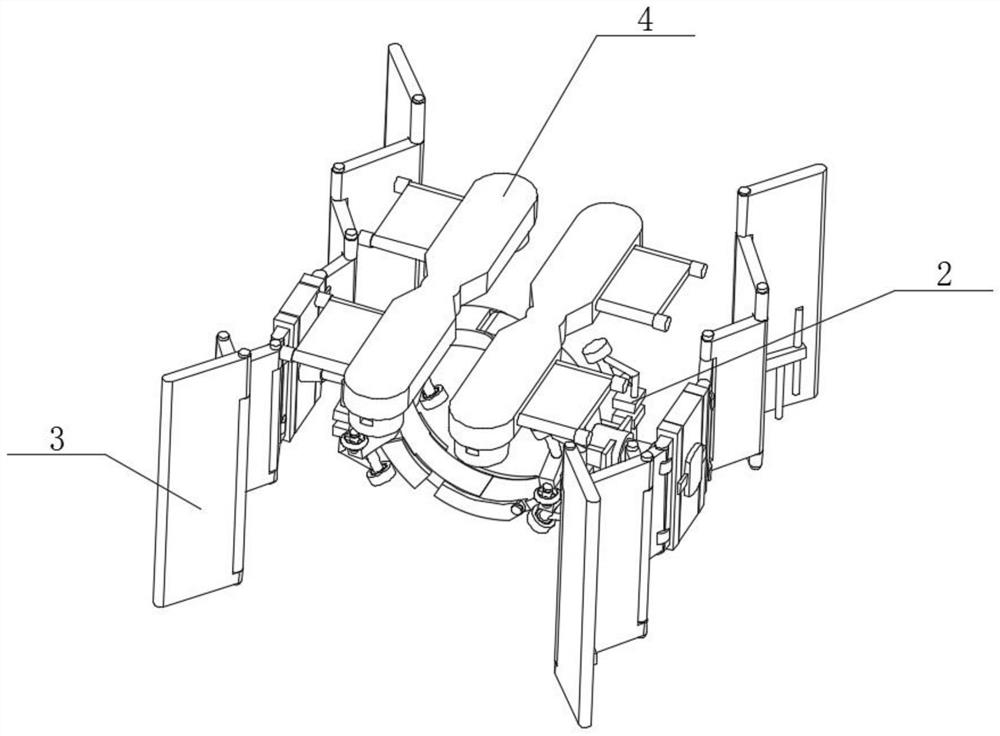

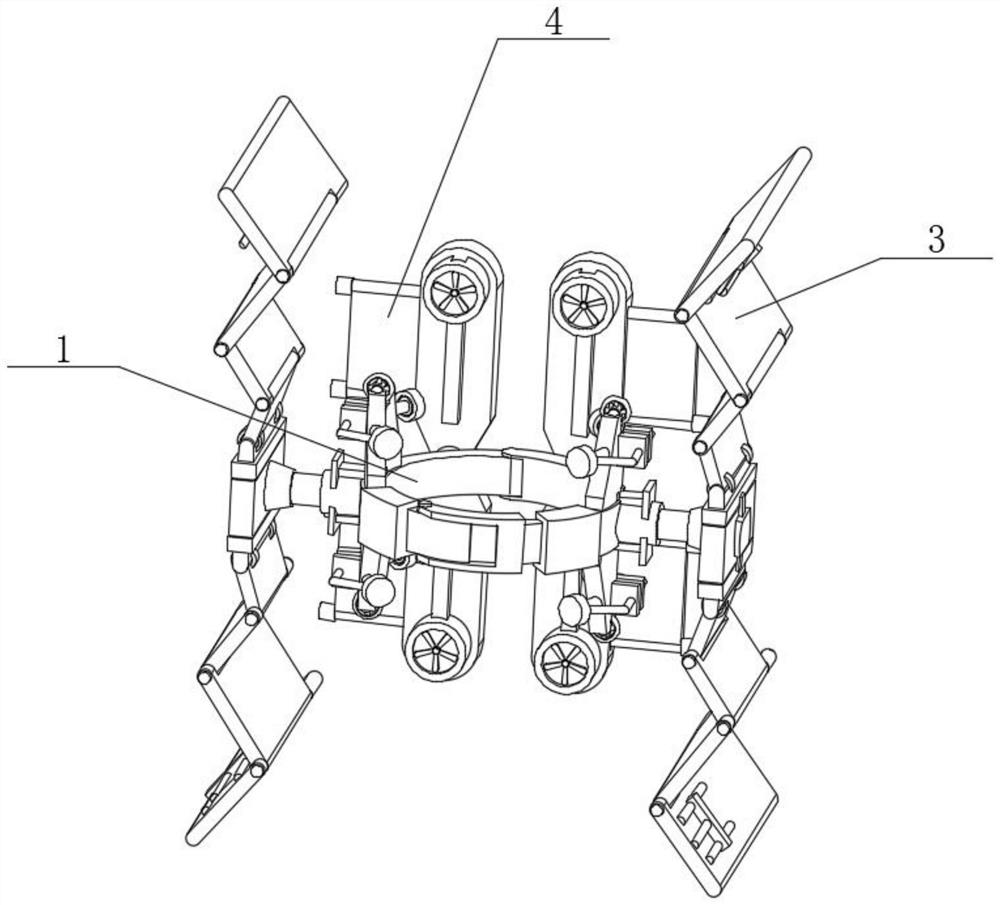

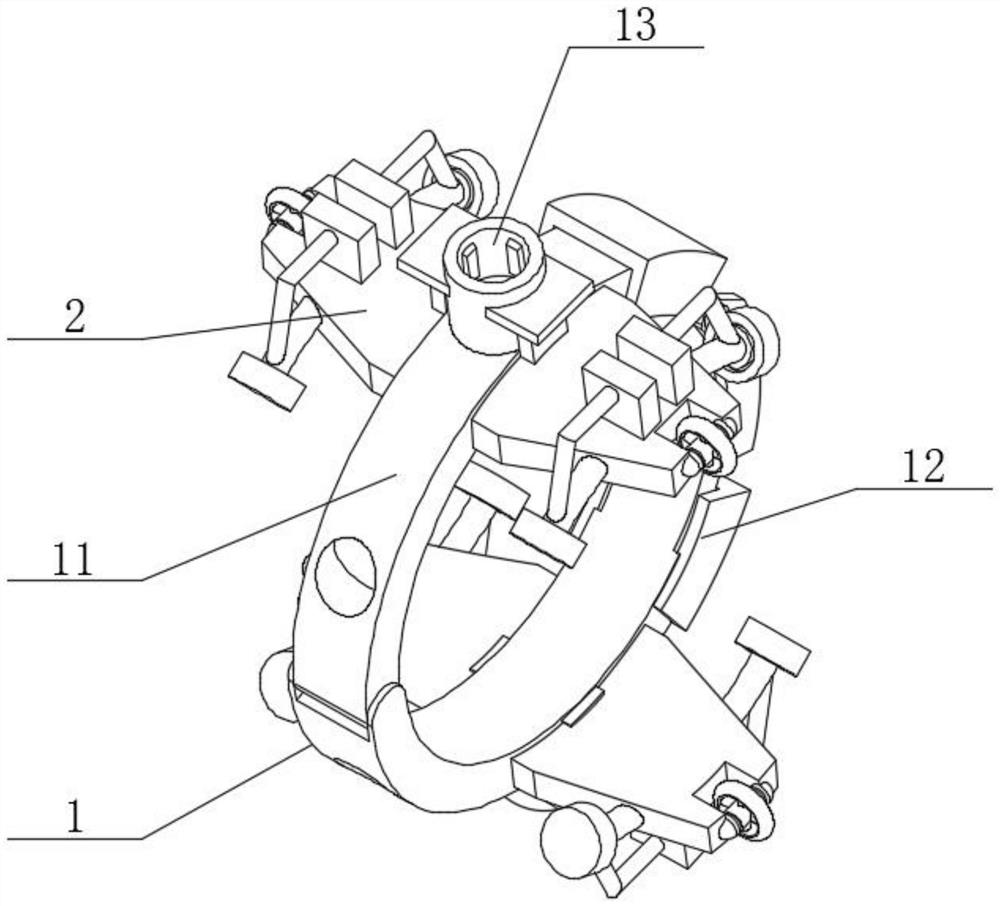

[0050] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the present invention provides a technical solution: a long-distance oil and gas pipeline automatic root welding pipe mouth windproof device, including a pipeline butt joint device 1, a moving device 2, a side protection device 3 and a top absorbing device 4, and the moving device 2 is installed on the On both sides of the pipe butt joint device 1, one end of the side guard 3 is connected inside the pipe butt joint device 1, the bottom of the top absorber 4 is connected to the top of the pipe butt joint device 1, and the side guard 3 is located on both sides of the pipe butt joint device 1 , the mobile device 2 is located between the pipe butt joint device 1 and the side protection device 3, the pipe butt joint device 1 includes a pipe clamping structure 11, a locking structure 12, a docking round pipe 13 and a lifting table 14, the two ends of the locking structure 12 are connected to the pipe clamp The...

Embodiment 2

[0053] Such as Figure 4 As shown, the pipe clamping structure 11 includes an arc-shaped rotating panel 111 and a clamping arc-shaped plate 112. One end of the clamping arc-shaped plate 112 is rotatably connected to one end of the arc-shaped rotating panel 111. The locking structure 12 includes a docking port 121, a locking The buckle 122 and the movable hasp 123, the docking port 121 is installed on one end of the locking buckle 122, the other end of the docking port 121 is movably connected with the pipe clamping structure 11, the locking buckle 122 is provided with two, and the movable hasp 123 is installed On the top of one of the locking gussets 122 , the other end of the movable hasp 123 is connected to the inside of the other locking gusset 122 .

[0054] In this embodiment, the arc-shaped rotating panel 111 expands its internal diameter by rotating with the clamping arc-shaped plate 112, so as to be deployed on the oil pipeline for use, and after the deployment is comp...

Embodiment 3

[0056] Such as figure 1 , figure 2 , image 3 , Figure 5 and Figure 6 As shown, the mobile device 2 includes a movable bearing panel 21, the top of the movable bearing panel 21 is provided with a reinforcing support plate 22, and one end of the movable bearing panel 21 is provided with a groove 24, and the inside of the groove 24 is provided with a first roller 25. Both sides of the load-bearing panel 21 are provided with auxiliary rollers 26, an elastic strut 23 is arranged between the auxiliary roller 26 and the movable load-bearing panel 21, and one end of the elastic strut 23 is connected to the inside of the movable load-bearing panel 21, and the elastic strut 23 The other end is connected to the inside of the reinforcement support plate 22 , the other end of the movable bearing panel 21 is connected to the outer wall of the pipe clamping structure 11 , and the lifting platform 14 is located at the intersection of the movable bearing panel 21 and the pipeline clampi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com