Cast iron sluice gate

An iron gate and cast iron technology, applied in the field of gates, can solve the problems of poor sealing water, short service life, poor corrosion resistance, etc., and achieve the effects of reducing friction resistance, long service life and improving wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

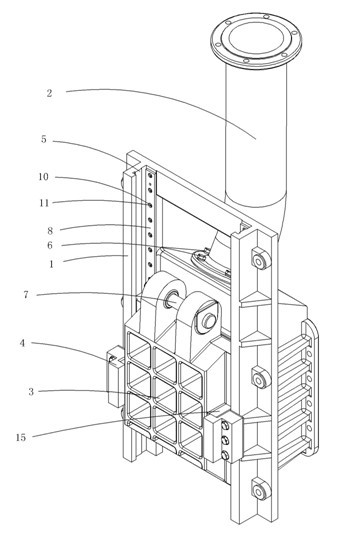

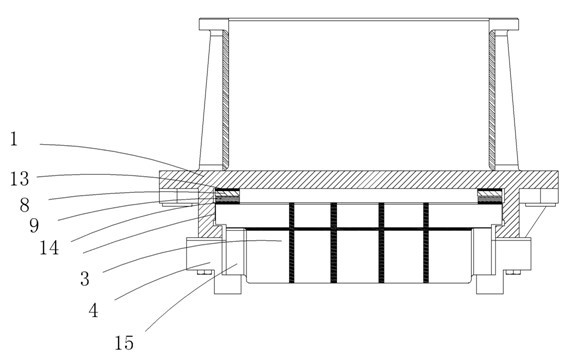

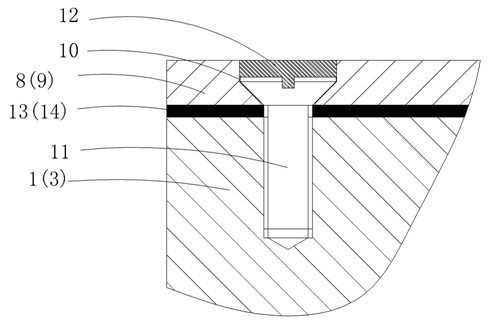

[0024] Figure 1 to Figure 3 A specific embodiment of the invention is shown in which figure 1 It is a structural schematic diagram of the present invention; figure 2 for figure 1 Transverse section of the cast iron gate shown; image 3 for figure 1 An enlarged partial cross-sectional view of a screw fastening in a cast iron gate is shown.

[0025] See Figure 1 to Figure 3 , a cast iron gate, comprising a cast iron door frame 1, a ventilation pipe 2, a cast iron door leaf 3, and a positioning device 4, one side of the cast iron door frame 1 is provided with a guide groove 5, and the ventilation pipe 2 is fixed on the cast iron door frame 1 by bolts 6, and On the upper air distribution chamber on the opposite side of the guide groove 5, the cast iron door leaf 3 is set in the guide groove 5 of the cast iron door frame 1, and the top of the cast iron door leaf 3 is set in a U shape, and the top of the U shape is connected by a suspension shaft 7. Connected, the cast iron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com