LED secondary reflection and IGBT (insulated gate bipolar transistor) control drive technology

A technology of secondary reflection and secondary optics, applied in reflectors, energy-saving control technology, medical lighting, etc., can solve the problems of high color rendering index of shadowless lamps, poor color rendering of light sources, good color rendering of light sources, etc. , to achieve the effect of less color distortion, high color rendering index and low temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

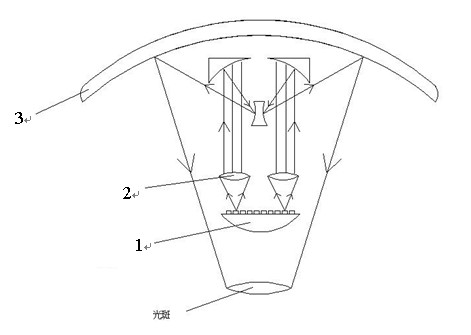

[0049] The invention relates to an LED secondary reflection and IGBT control drive, which is used for color rendering of shadowless lamps by combining LED color mixing technology or white light technology with secondary optical reflection, wherein,

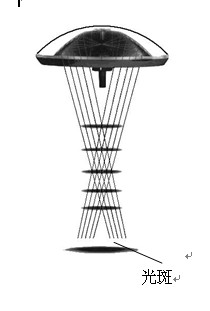

[0050] The LED color mixing technology is as follows: arrange different numbers of red, green, white, and yellow LEDs in sequence with a microprocessor for real-time adjustment of the proportional relationship, focus through an optical lens, integrate them into nearly parallel spectra, and then pass Secondary optical reflection, color mixing of these four primary colors of LEDs, and finally at a distance of 1 meter from the light emitting surface of the shadowless lamp, a spot with a diameter of 220mm+ / -20mm is formed, and the rated light intensity Ec at the center of the spot is above 140,000lux.

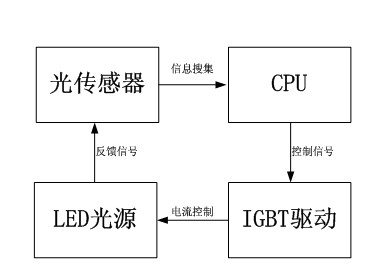

[0051] Such as image 3 IGBT As shown in the driving schematic diagram, IGBT is used to control the drive, and a light sensor is in...

Embodiment 2

[0069] Others are all identical with embodiment 1, just as Figure 7 As shown, in order to remove the aluminum plate under the LED light board, it is directly connected to the heat sink mechanism.

Embodiment 3

[0071] The structure is the same as that of Example 2, the LED is monochromatic white light, and the monochromatic white light LEDs with a color temperature limited to 4000-4500K are arranged in sequence, focused by an optical lens, integrated into a nearly parallel spectrum, and then through secondary optical reflection, Finally, at a distance of 1 meter from the light emitting surface of the shadowless lamp, a spot with a diameter of 220mm+ / -20mm is formed, the rated light intensity Ec at the center of the spot is not less than 140,000lux, and the color rendering index of the light output is not less than 92%.

[0072] If it is a white LED, there is no need to adjust the color temperature, but the color temperature of the white LED used must be limited between (4000-4500K). Therefore, the price is cheaper than that of Embodiment 1 and Embodiment 2, and is applicable to hospitals with poor basic equipment and insufficient funds.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com