Quantitative risk analyzing method for pressure equipment with embed crack defect

A technology for pressure-bearing equipment and risk analysis, which is applied in the direction of analyzing materials, measuring devices, and special data processing applications, and can solve problems such as the inability to achieve risk assessment of pressure-bearing equipment with buried crack defects

Inactive Publication Date: 2012-09-12

NANJING UNIV OF TECH

View PDF1 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] The purpose of the present invention is to solve the problem of ignoring the influence of buried crack defects and being unable to realize the risk assessment of pressure equipment containing buried crack defects whe

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

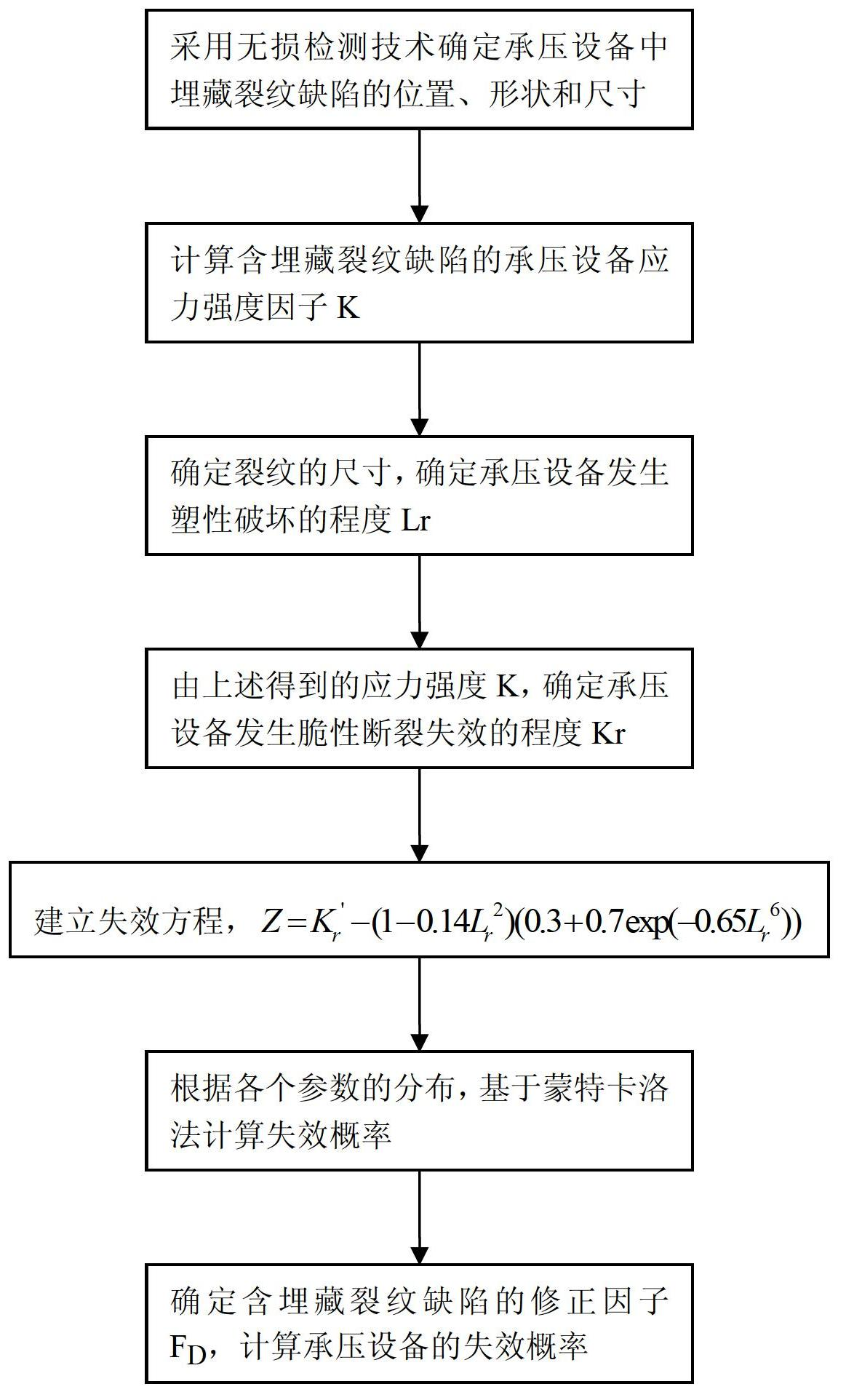

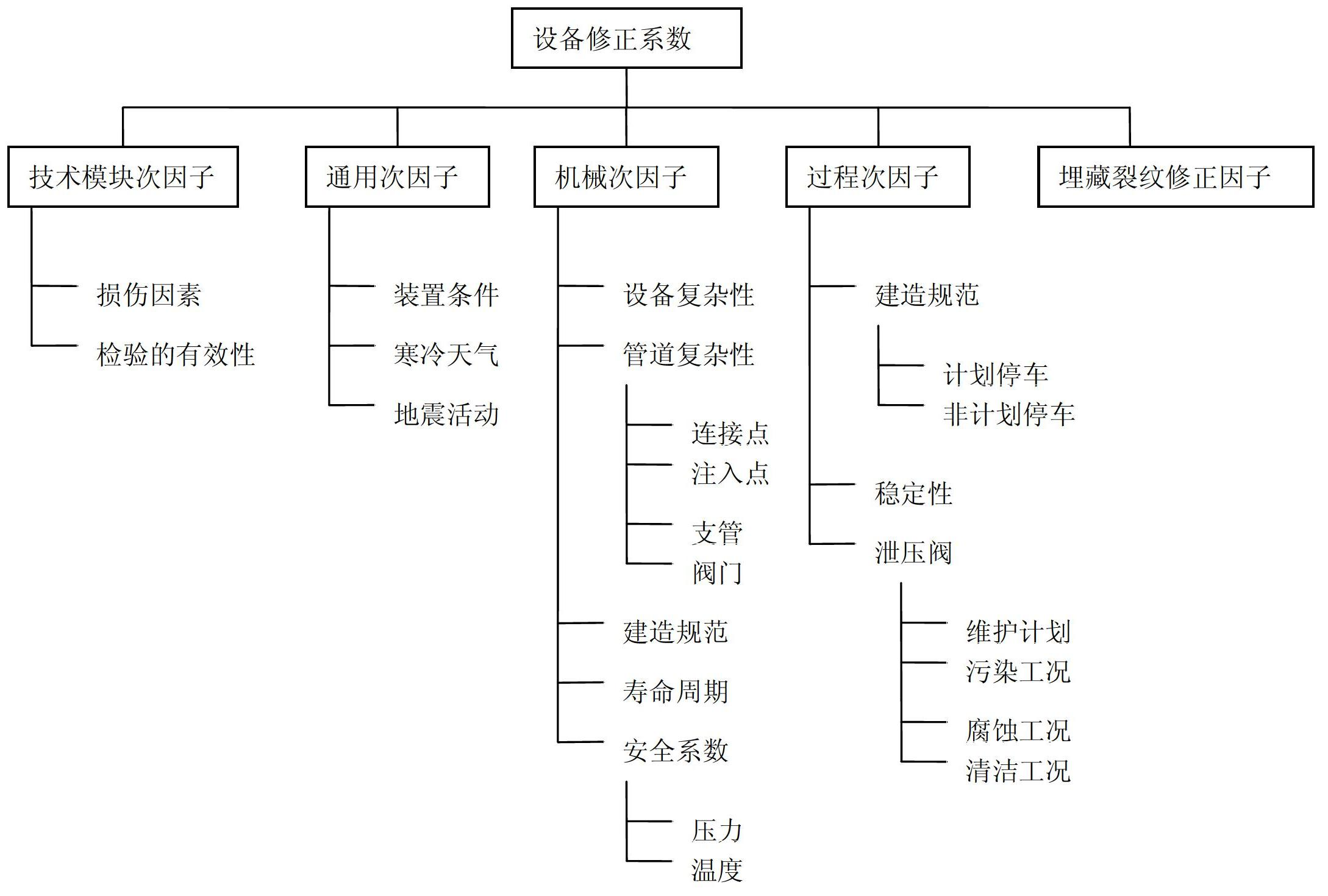

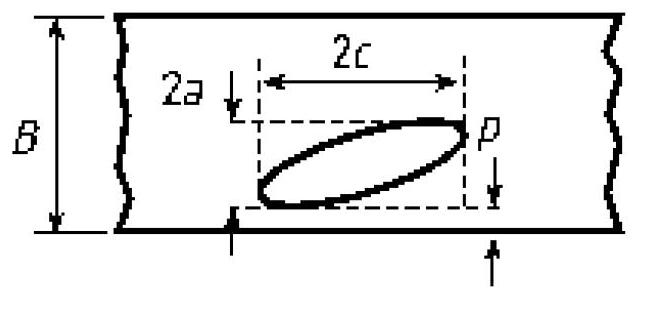

The invention discloses a quantitative risk analyzing method for pressure equipment with embed crack defect. The quantitative risk analysis method comprises the following steps of: 1, carrying out nondestructive detection on the pressure equipment to be analyzed; 2, calculating a stress strength factor value of the pressure equipment with the crack defect; 3, calculating a degree of plastic failure occurrence of the pressure equipment Lr; 4, calculating a degree of brittle fracture failure occurrence of the pressure equipment Kr'; 5, establishing a failure equation, and substituting an Lr value and a Kr' value into the equation to calculate according to a formula Z=Kr'-(1-0.14Lr2)(0.3+0.7exp(-0.65Lr6)); 6, calculating failure probability of the crack defect by using a Monte Carlo method; and 7, determining a correction factor of the embed crack defect FD, and calculating the failure probability of the pressure equipment. The quantitative risk analyzing method for the pressure equipment with the embed crack defect provided by the invention considers the influence of the embed crack defect on the pressure equipment, so that the precision of a risk analyzing result is improved. The quantitative risk analyzing method for the pressure equipment with the embed crack defect has high pertinence and is more reasonable when the pressure equipment is checked and maintained.

Description

technical field [0001] The invention relates to the field of risk analysis of pressure equipment, and relates to a method for quantitative risk analysis of pressure equipment with buried crack defects. Background technique [0002] Pressure-bearing equipment refers to pressure vessels, pressure pipes, boilers, pressure-bearing accessories, etc. with pressure as the basic load, which involves life safety and is relatively dangerous. With the advancement of science and technology and the development of industrial production, the use of pressure equipment is becoming more and more extensive. At present, pressure equipment has become the chemical industry, petroleum industry and petrochemical industry, coal, metallurgy, atomic energy, aerospace, marine engineering, light industry, It is of great significance to ensure the safe and reliable operation of important equipment in various departments such as textiles, food, and urban construction, to protect the lives and property of ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N3/00G06F19/00

Inventor 赵建平肖凌桀潘硕

Owner NANJING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com