Structure for fixing complete front shell and liquid crystal module of liquid crystal television

A technology for liquid crystal modules and liquid crystal TVs, which is applied to parts of color TVs, parts of TV systems, TVs, etc., can solve the problems of high cost and complicated assembly process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

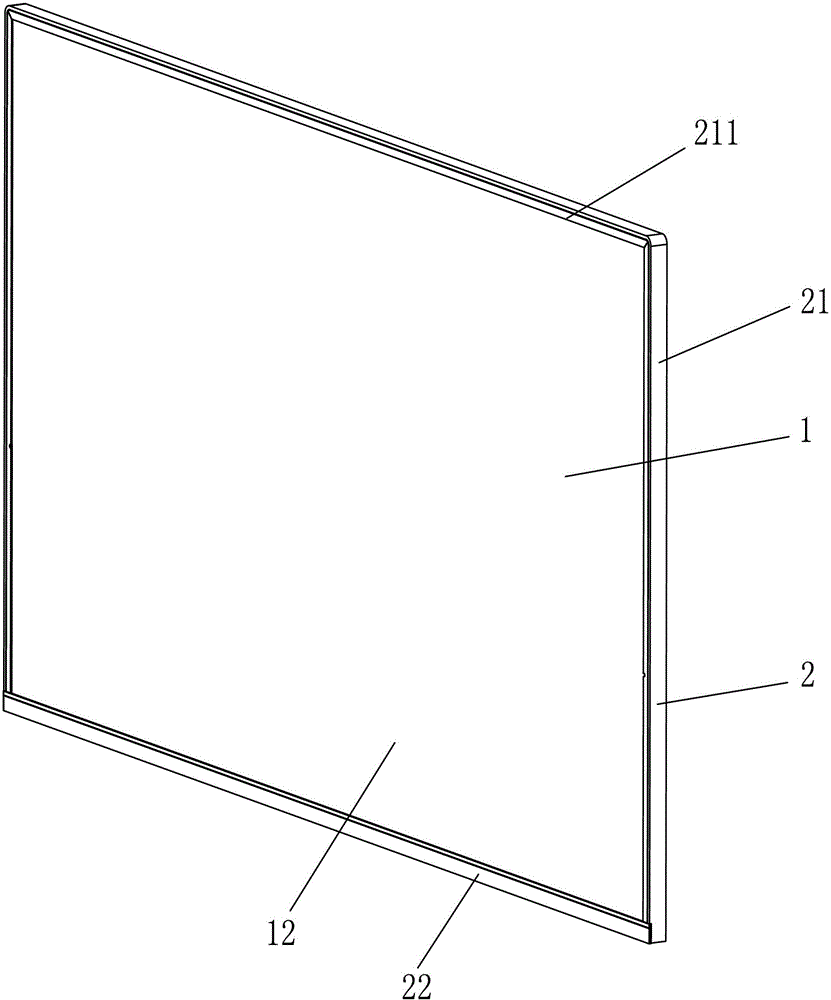

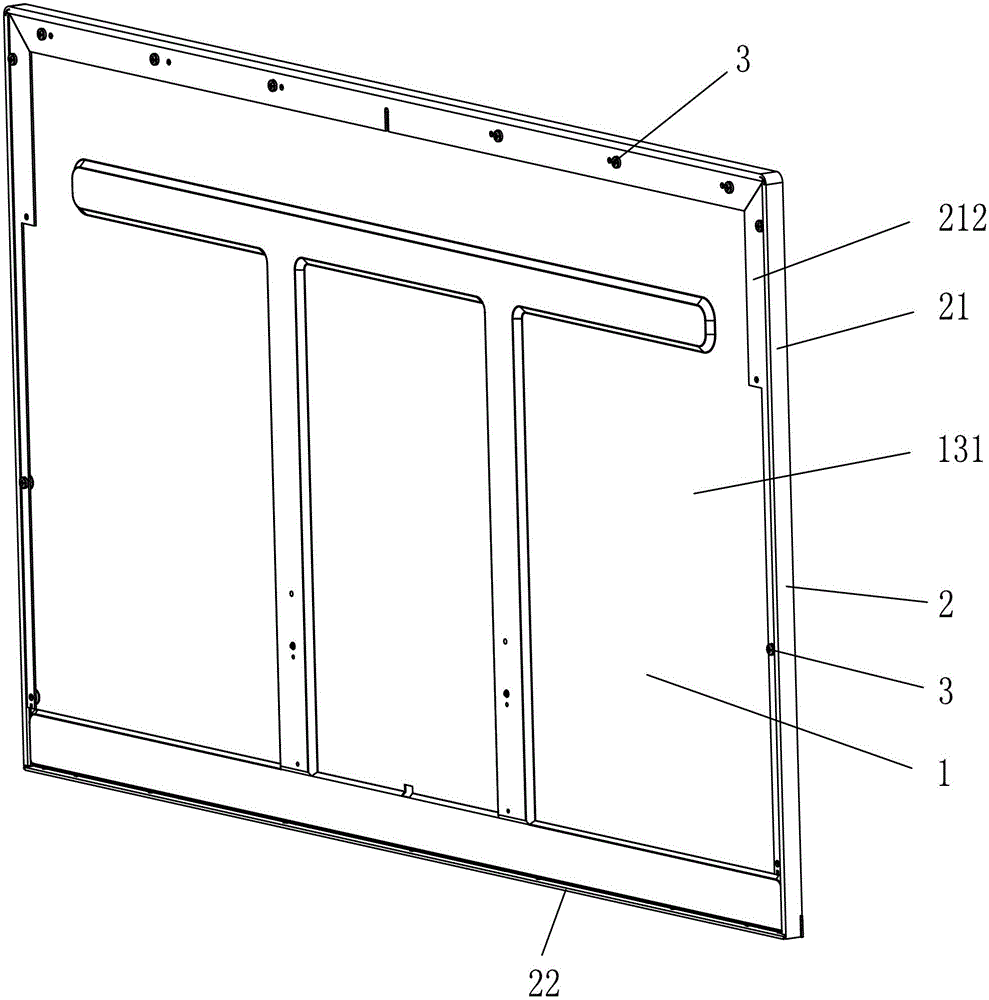

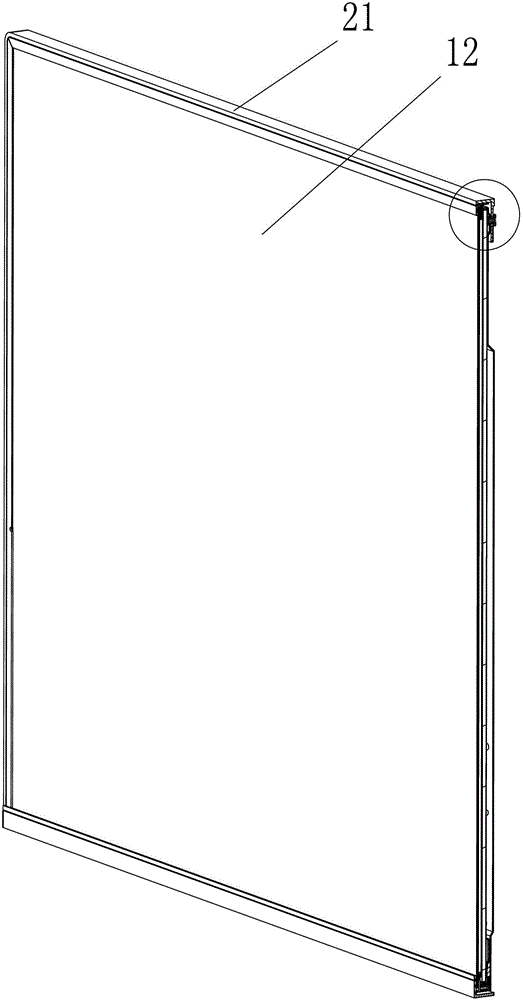

[0020] Example: such as Figure 1 to Figure 5 As shown, a fixed structure of a liquid crystal TV complete front case and a liquid crystal module includes a liquid crystal module 1 and a complete front case 2, and the complete front case 2 includes a U-shaped A frame 21 and a bottom frame 22, the bottom frame 22 is fixed on the liquid crystal module 1, the cross section of the U-shaped frame 21 is U-shaped, and the edge of the liquid crystal module 1 is fixed on the front of the U-shaped frame 21 In the draw-in slot 213 between the frame portion 211 and the rear frame portion 212, the rear frame portion 212 of the U-shaped frame 21 is screwed with an adjusting screw 3, the adjusting screw 3 has front and rear two sections of threads, and the adjusting screw 3 The pitch of the front thread 31 is smaller than the pitch of the rear thread 32, the front thread 31 of the adjustment screw 3 is screwed with the first screw hole 1311 of the back plate 131 of the backlight module 13 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com