Welding workbench capable of precisely controlling gap and precise gap control method

A workbench and gap technology, applied in welding equipment, manufacturing tools, auxiliary welding equipment, etc., can solve problems affecting the accuracy of welding fixtures, weld pores, and affect welding joints, etc., to achieve precise gap control, improve welding efficiency, The effect of reducing tedious work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

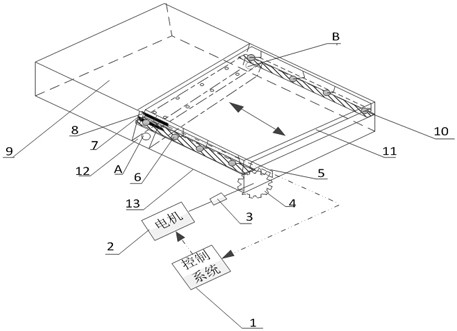

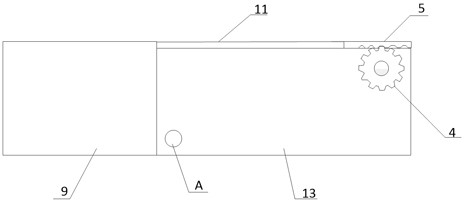

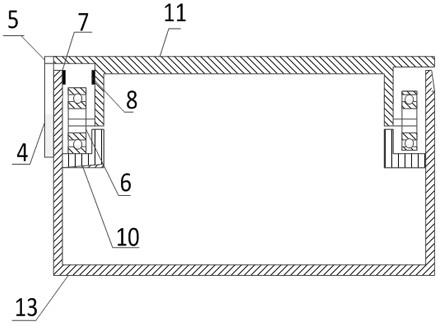

[0024] Such as Figure 1-4 As shown, a welding workbench with precise gap control includes a fixed table 9, a fixed seat 13, a shielding gas flow channel 12, a sliding table 11, a traveling mechanism, a displacement sensor and a control system 1.

[0025] The fixed table 9 is fixedly mounted on one end of the fixed seat 13, the slide table 11 is supported on the fixed seat 13, and a traveling mechanism is arranged between the slide table 11 and the fixed seat 13. Described walking mechanism comprises motor 1, shaft coupling 3, gear 4, rack 5 and guiding mechanism; Described gear 4 is installed on the holder 13, and rack 5 is fixedly installed on the slide table 11, and gear 4 and The rack 5 meshes. The output shaft of the motor 2 is connected with the gear 4 through a shaft coupling 3 . A guiding mechanism is arranged between the slide table 11 and the fixed seat 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com