Fault diagnosis method of random fuzzy fault characteristic fusion rotating mechanical device

A technology of rotating machinery equipment and fault characteristics, which is applied in the field of fault diagnosis of rotating machinery equipment, and can solve problems such as errors and inaccuracies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

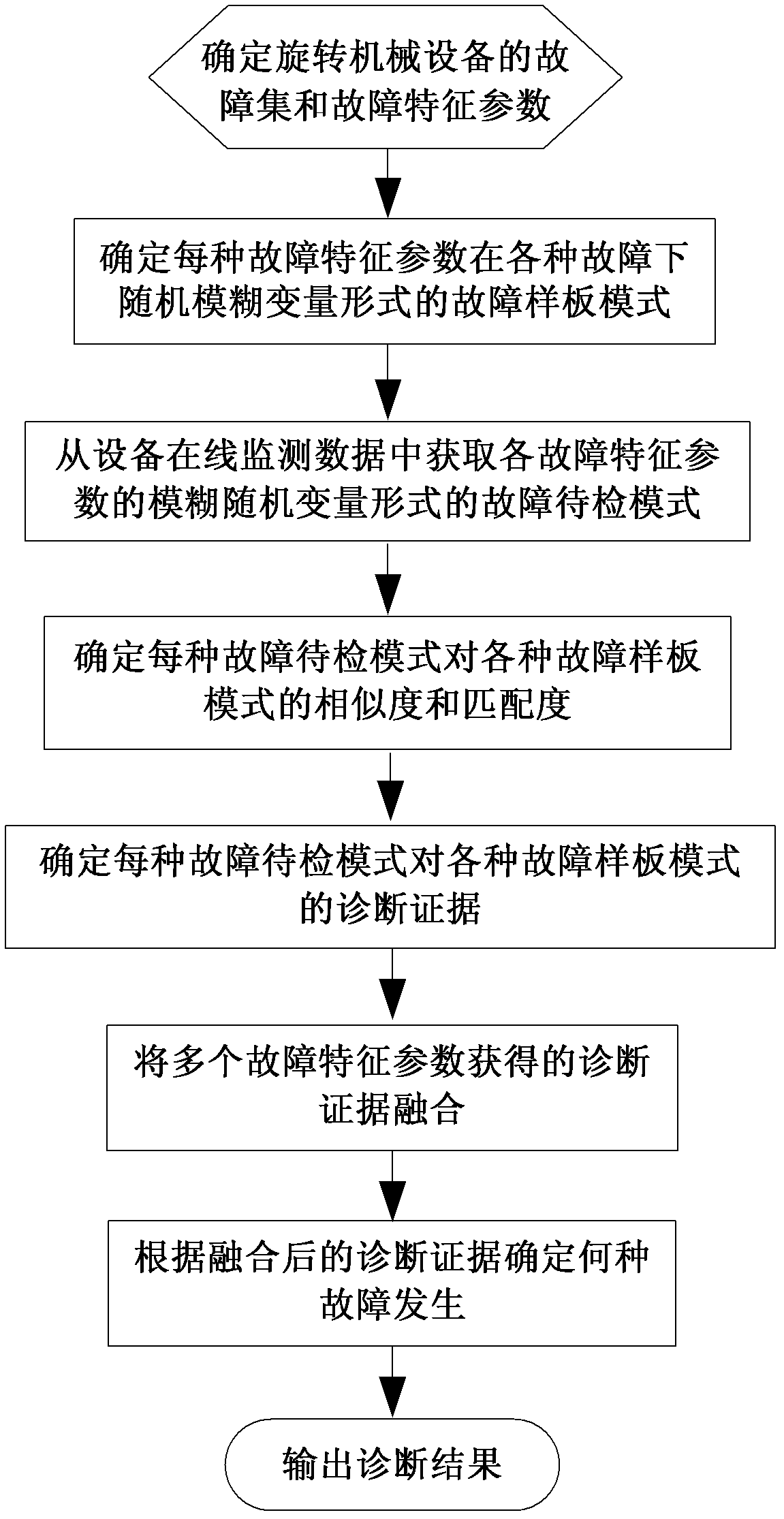

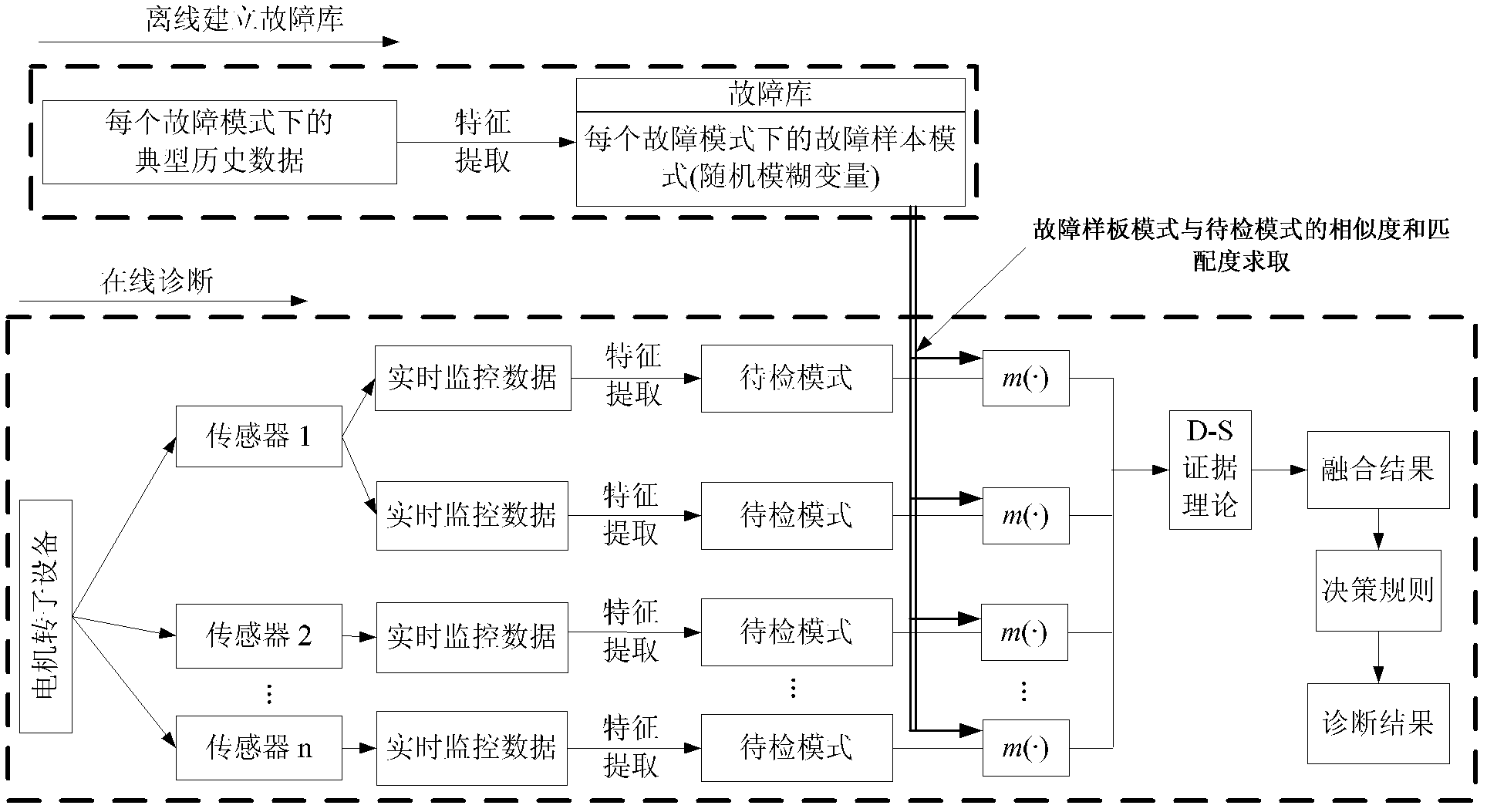

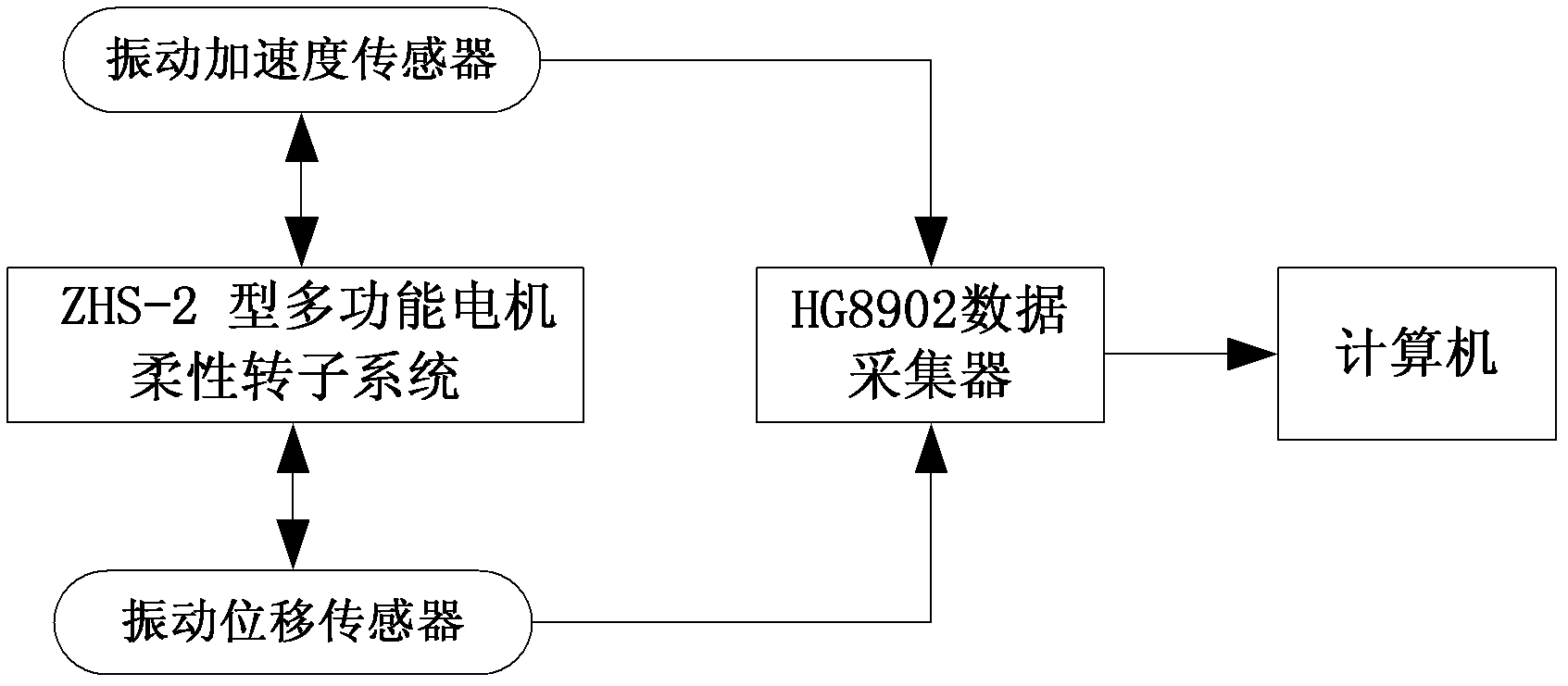

[0060] A method for fault diagnosis of rotating mechanical equipment based on fusion of random fuzzy fault features proposed by the present invention, the flow chart of which is as follows figure 1 shown, including the following steps:

[0061] (1) Set the fault set of rotating mechanical equipment Θ={F 1 ,...,F j ,...,F N}, F j Represents the jth fault in the fault set Θ, j=1, 2, ..., N, N is the number of faults contained in the equipment;

[0062] (2) Let x be able to reflect each fault F in the fault set Θ j The fault characteristic parameters of x, establish the fault template mode A of the fault characteristic parameter x xj , A xj To describe the fault F j A random fuzzy variable of A xj The steps to obtain are as follows:

[0063] (2-1) When the fault F in the fault set Θ j When it occurs, use the sensor to measure the fault characteristic parameter x, and obtain δ measured values of x continuously;

[0064] (2-2) Utilize these δ measured values to obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com