Dust collector for cutting machine

A dust collection device and cutting machine technology, which is applied to the attachment of sawing machines, sawing machine devices, sawing equipment, etc., can solve the problems of inconvenient use and difficulty in collecting cutting dust from saw blades, and achieve the effect of preventing poor movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

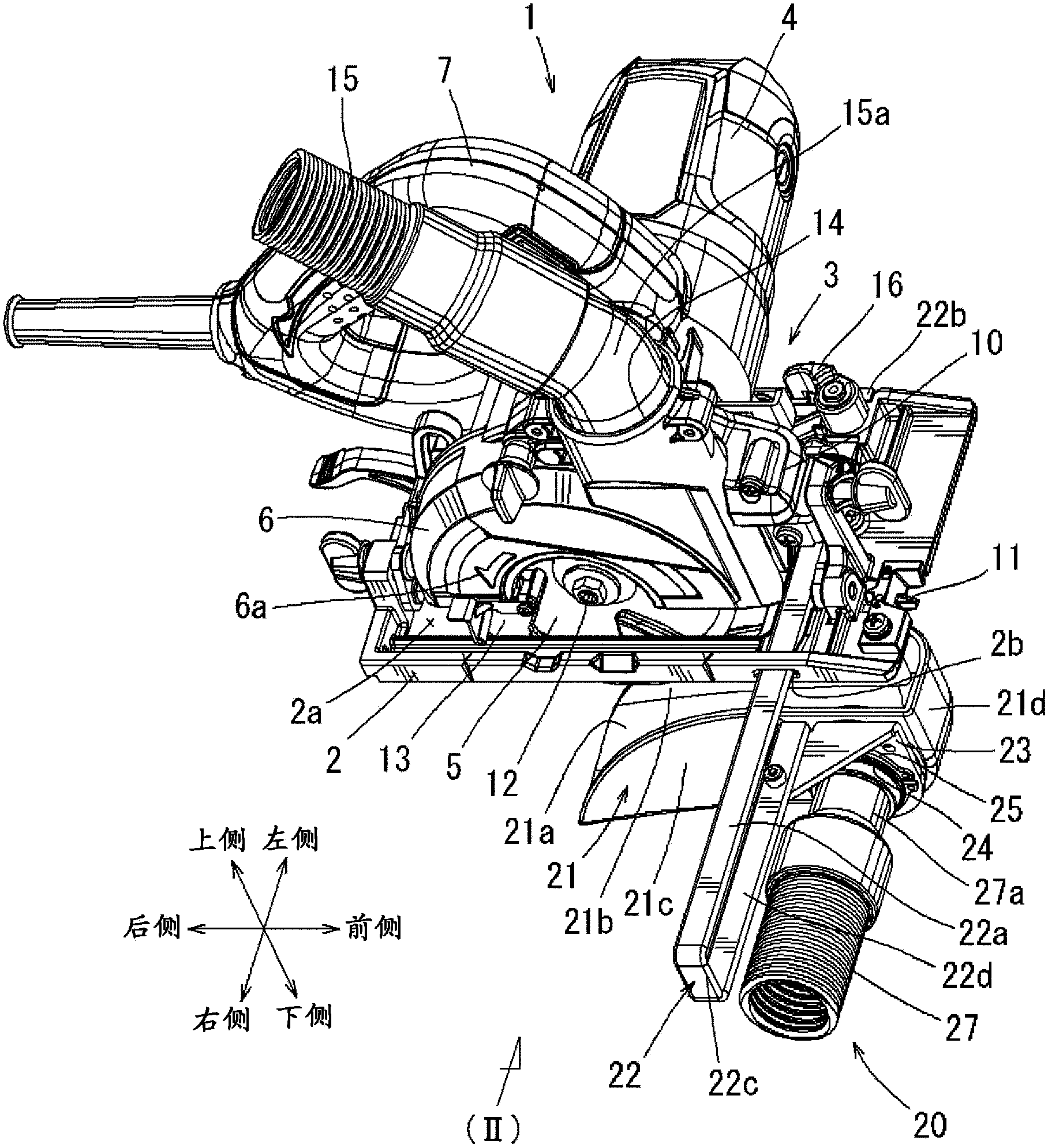

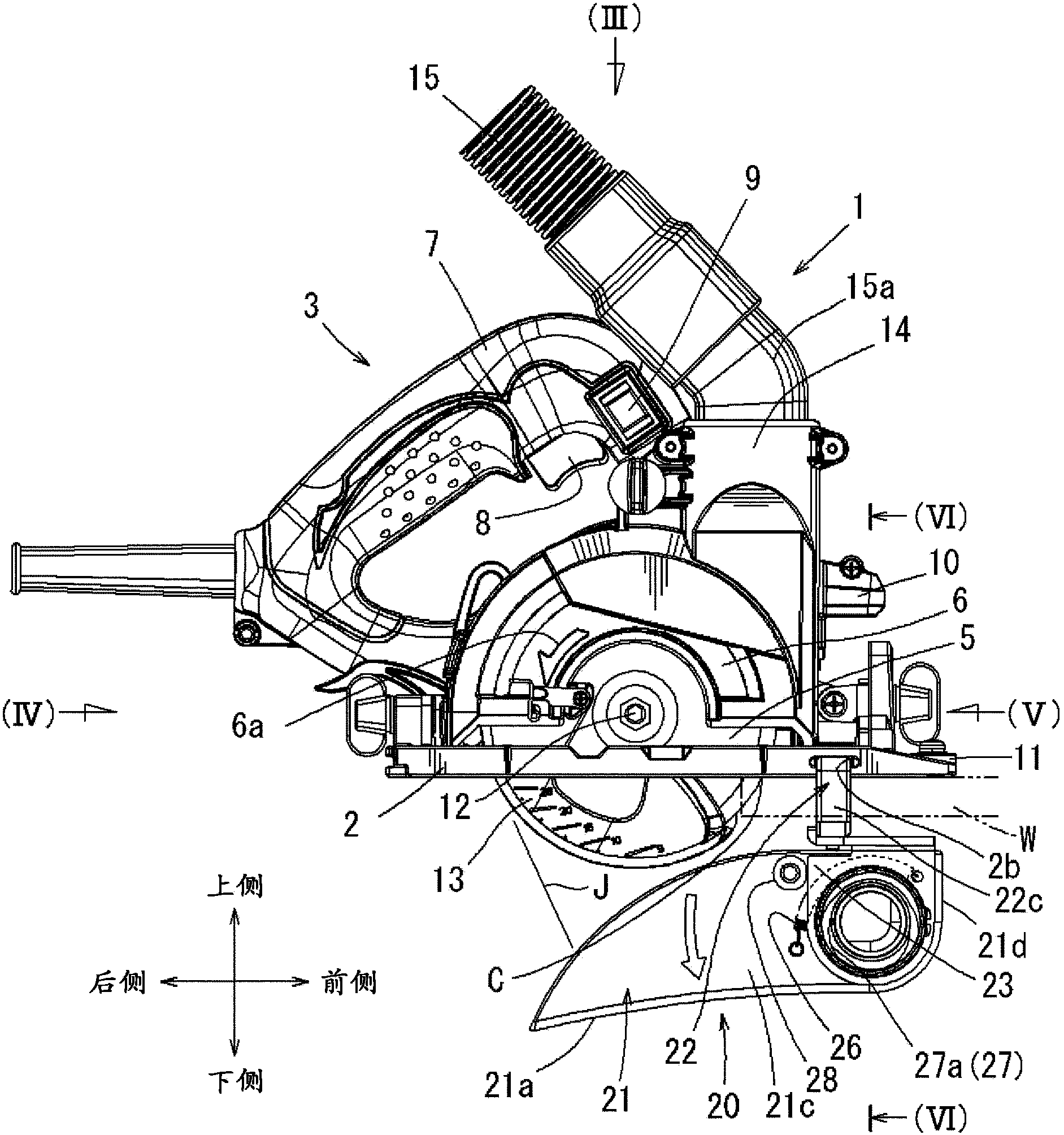

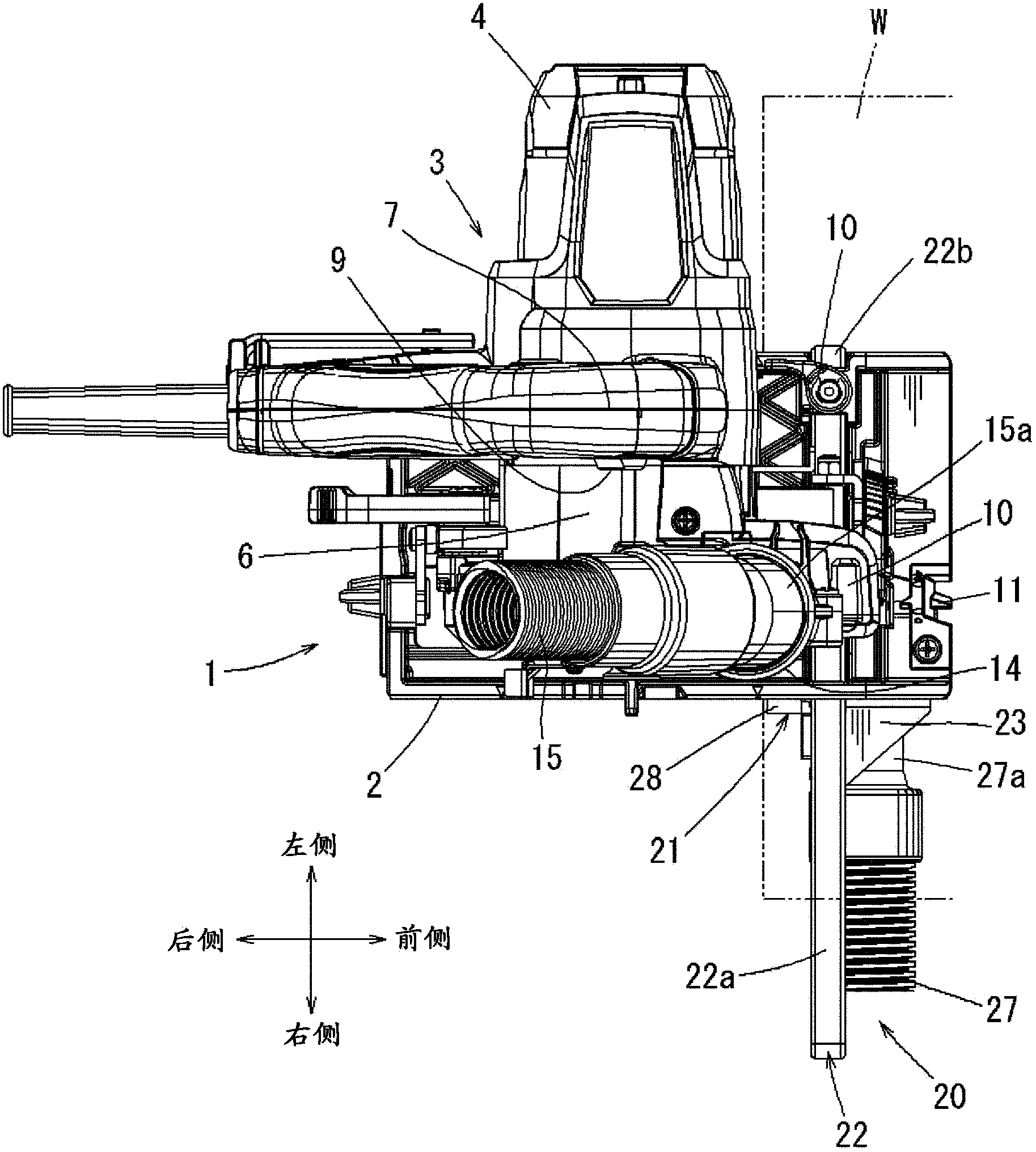

[0038] Refer below Figure 1~Figure 6 Specific embodiments of the present invention will be described. Figure 1~Figure 5 It is an overall view of the portable cutting machine 1 provided with the dust collector 20 of this embodiment. Except for the dust collecting device 20, the structure of the cutting machine 1 itself is conventionally known, and there is no special change in this embodiment, so it will only be briefly described.

[0039] In addition, in figure 1 , the user is located at the rear side of the cutting machine 1 . In the following description, front and rear, left and right, and up and down directions are all based on the user. In addition, each direction is marked in the figure.

[0040]The cutter 1 has a rectangular plate-shaped base 2 for being placed on the upper surface of a workpiece W to be cut, and a cutter main body 3 supported on the upper surface of the base 2 . The cutter body 3 has an electric motor 4 as a drive source, and a circular cutting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com