Safety cutter for jam prevention

A cutter and anti-pinch technology, applied in metal processing, sending objects, thin material processing, etc., can solve problems such as finger scratches, finger pain, unsmooth cutting, etc., and achieve the effect of safe cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings. This is only to enable those of ordinary skill in the art to which the present invention pertains can easily implement the present invention for the purpose of describing the present invention in detail, and does not mean that the technology of the present invention Thoughts and scope are limited to this.

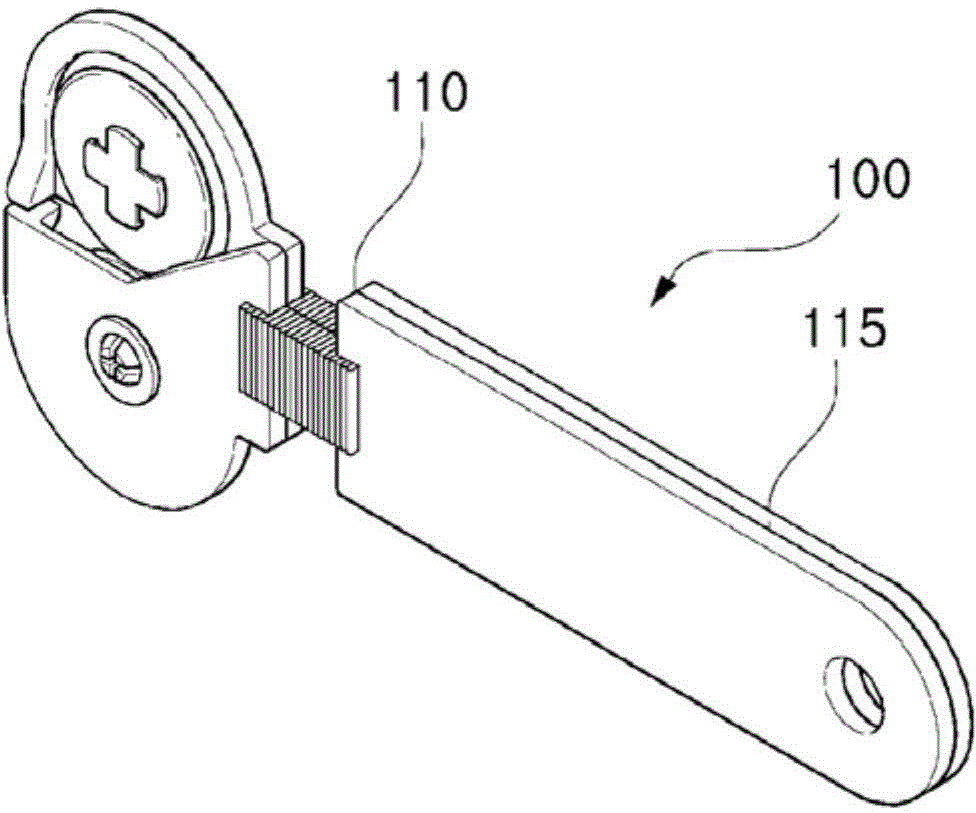

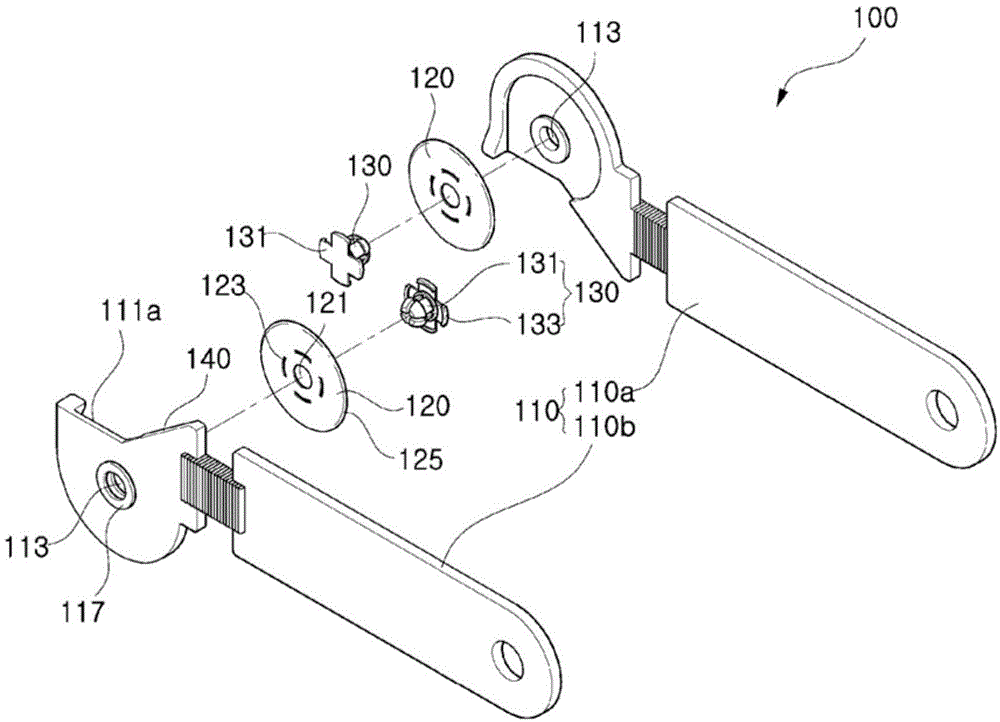

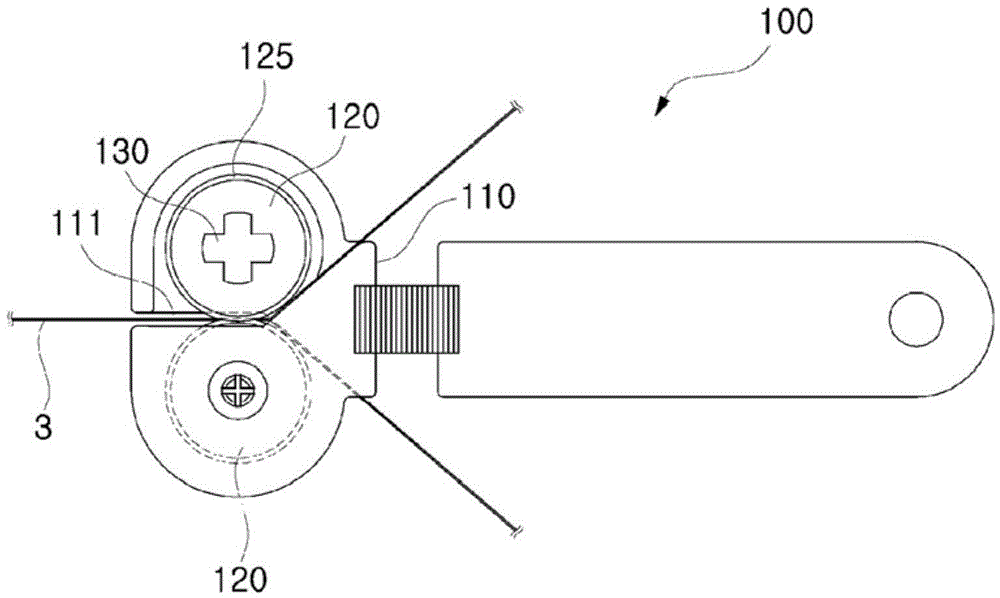

[0056] The anti-pinch type safety cutter 100 of the first embodiment of the present invention can not only make the disc-shaped rotating cutting member 120 rotate across the center of the object to be cut 3 by means of only the driving force without cutting, Thereby, the object to be cut can be cut quickly, easily and safely, and especially when the advancing direction of the disc-shaped rotary cutting member 120 is converted into an oblique line or a curve, the pinching phenomenon caused by the object to be cut can be prevented, such as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com