Method for cutting water quenching slag ladle

A technology of water-quenched slag and cutting tools, which is applied in the field of machinery, can solve problems such as safety accidents, operator pollution, and impact on human health, and achieve the effects of less dust pollution, safe operation, and elimination of hidden dangers of personal accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

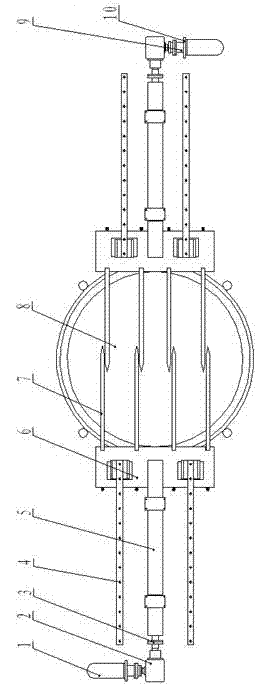

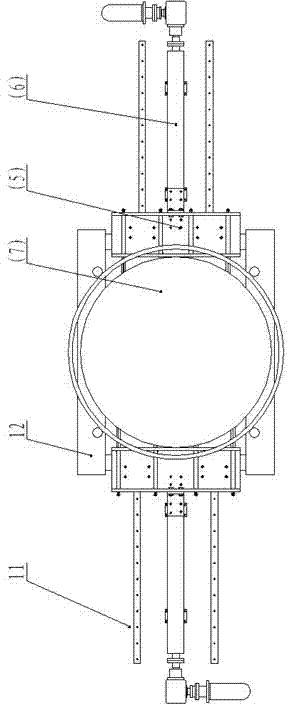

[0012] figure 1 and 2 Middle, 1. Servo motor, 2. Conversion box, 3. Coupling, 4. Guide rail pair, 5. Transmission mechanism, 6. Cutting device, 7. Cutting knife, 8. Water quenching slag bag, 9. Synchronous transmission shaft, 10. Flange, 11. Support base, 12. Unloading rack.

[0013] The method for cutting the water-quenched slag bag of the present invention is to set cutting knives 8 on the left and right sides of the water-quenched slag bag, and cut the water-quenched slag bag 8 placed on the discharge rack 12 by moving the cutting tool 7 horizontally. The working part of the cutting tool adopts the suspension method. The suspension means that there is no support or fixing frame in the working part of the cutting tool. The purpose is to prevent the raw material from falling into the fixing frame of the cutting tool and affect the continuous operation of the cutting tool. The cutting tools 7 on the left and right sides are asymmetrically distributed and inserted from the bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com