Wire cutting device of wire electric discharge machine

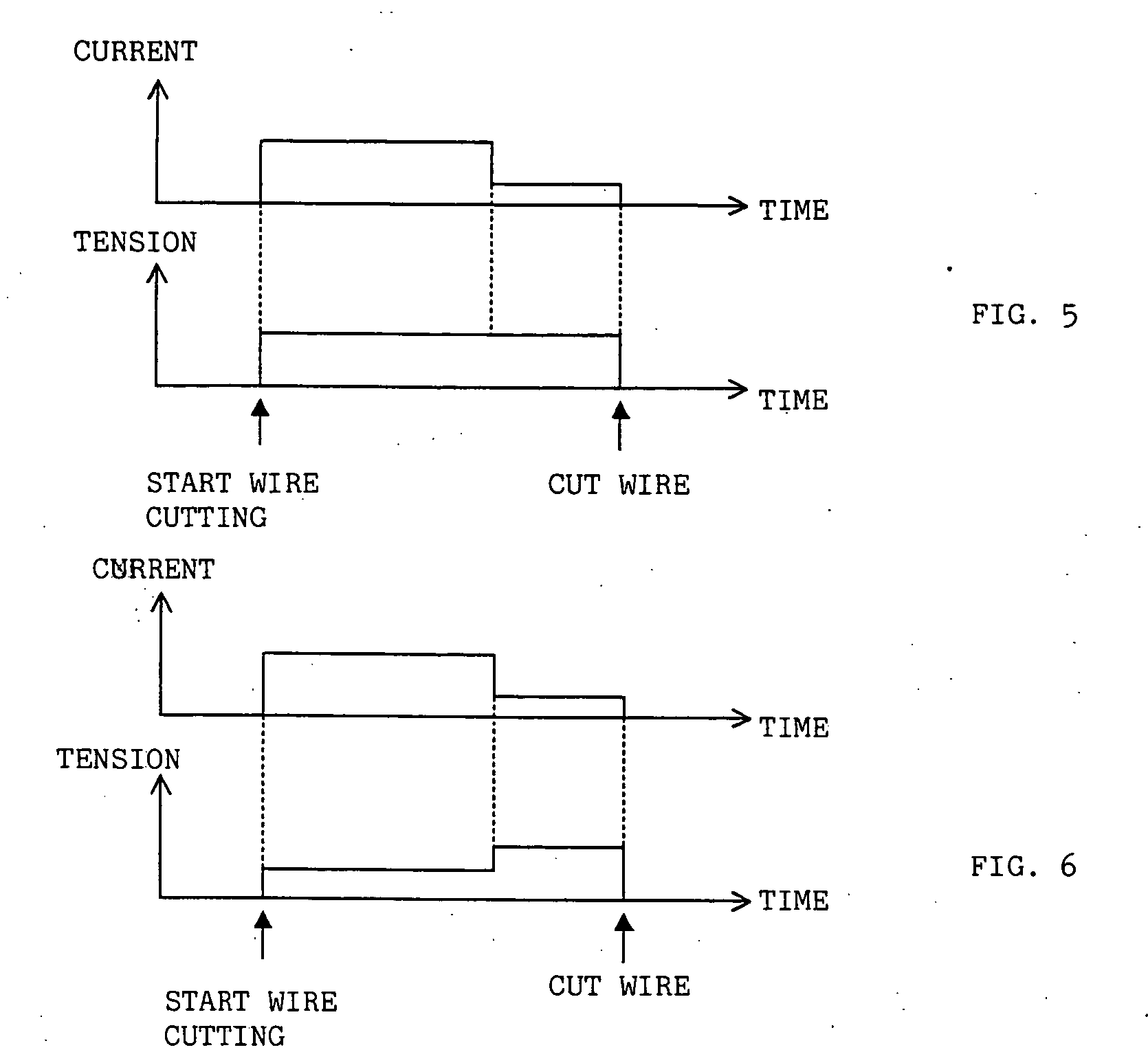

a wire electric discharge machine and cutting device technology, applied in the direction of electrical-based machining apparatus, metal-working apparatus, manufacturing tools, etc., can solve the problems of wire connection failure, wire cannot be inserted smoothly, and takes time for wire connection, so as to reduce the time for cutting wire, increase tension, and reduce current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

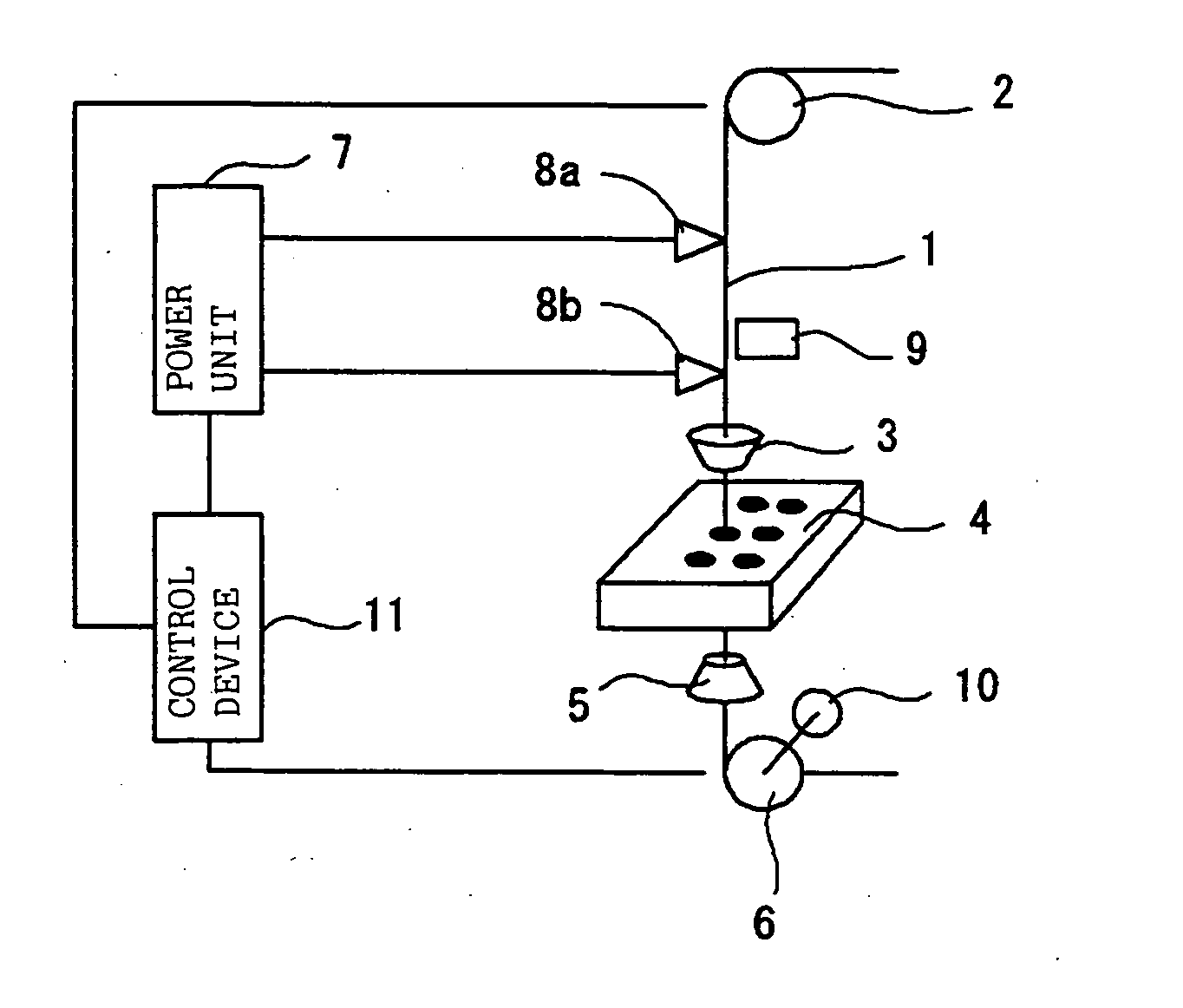

[0027]FIG. 1 is a configuration diagram showing the outline of a wire cutting device of a wire electric discharge machine which is related to an embodiment of the present invention. In FIG. 1, a wire 1 is fed by a take-up roller 6, which is rotary driven by a wire drive motor (not shown), through a roller with brake 2, an upper guide 3, a workpiece 4 of an object to be machined, and a lower guide 5. Conducting elements 8a and 8b are connected to the wire at the fusing positions, which are established between the roller with brake 2 and the upper guide 3, and a current for initiating fusion of the wire is supplied from a power unit 7 through the conducting elements 8a and 8b. Also, a wire temperature detection device 9 for detecting a wire temperature in a noncontact state with the wire is disposed so as to face the fusing positions on the wire 1. The wire drive motor (not shown) for rotary driving a brake function of the roller with brake 2 and the take-up roller 6 constitutes a ten...

PUM

| Property | Measurement | Unit |

|---|---|---|

| supply current | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| current | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com