Filter element and method for manufacturing filter element

一种过滤元件、密封件的技术,应用在过滤元件领域,达到保证稳定性、改进连接的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

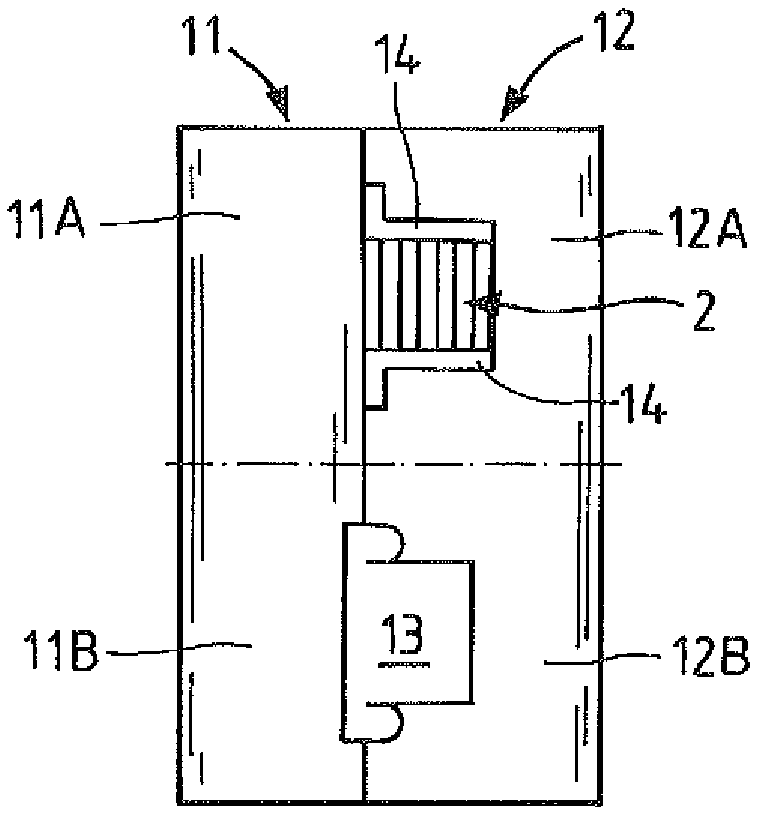

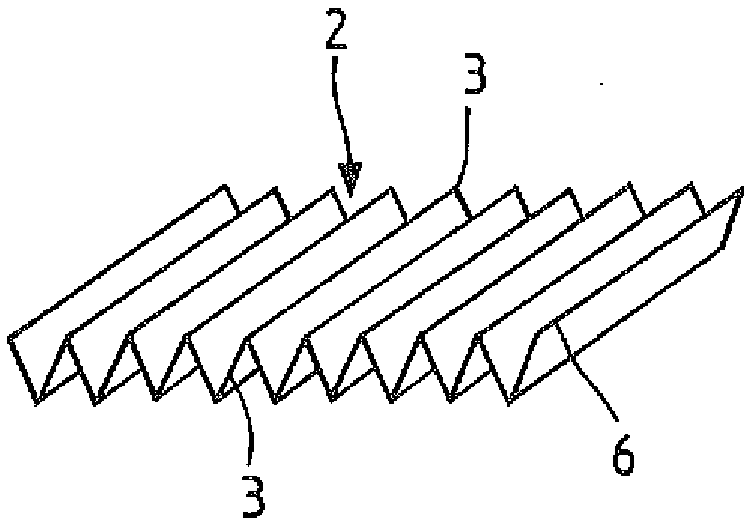

[0033] With the help of figure 1 To 3 show the first embodiment of the filter element in a simplified manufacturing state. figure 1 For this, a perspective view of the corrugated structure 2 is shown. The pleated structure 2 is formed of, for example, a filter fiber mesh material, in which a known mechanism such as a knife pleated structure or a rotary pleated structure can be used. For example, the filter fiber web material may be heat-treated to better fix the pleated profile 3. in figure 1 In the diagram, you can see the front and back fold contours 3. Reference numeral 6 shows the front end folds. Usually the side bands are now glued to the fold contour 3 in order to give stability to the entire fold structure 2. This is not necessary for the filter element proposed by the present invention.

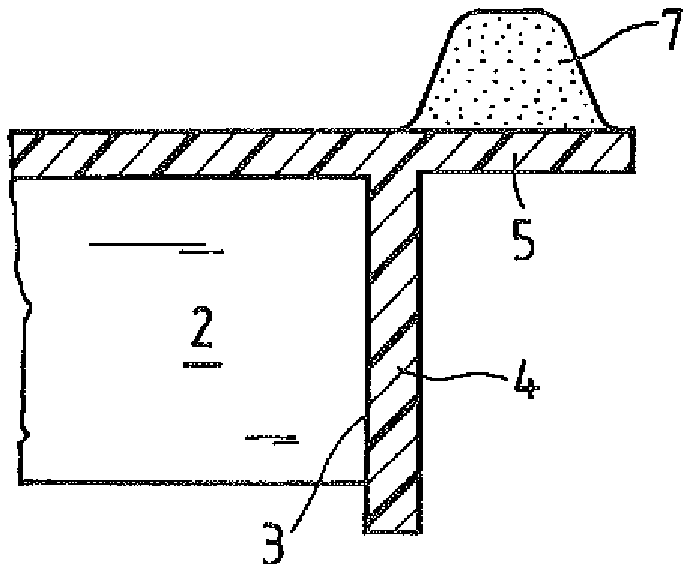

[0034] figure 2 Shows a perspective view of the corrugated structure 2 that has been provided with a plastic frame 4 of injection. The fold structure 2 is fixed to the injected pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com