Method for operating blast furnace

A technology of blast furnace operation and biomass coking, which is applied to blast furnaces, blast furnace details, furnaces, etc., can solve problems such as low calorific value and high moisture content, and achieve the effect of reducing CO2 emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

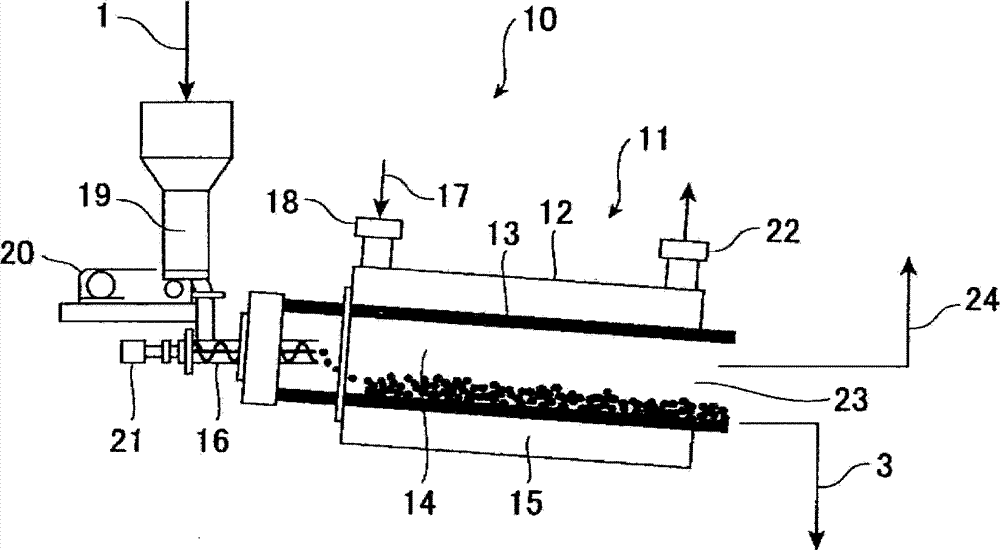

[0064] use figure 2 The shown rotary kiln apparatus performs dry distillation of biomass to perform a production test of biomass coke. The heating method of the rotary kiln is three-stage (3 division) electric heating. The inner diameter of the rotary furnace is 15 cm, the length is 1.0 m, the inclination angle is 1 degree, the carbonization temperature is 375° C., and the carbonization time is 50 minutes (rotary furnace speed: 1.5 rpm). As the biomass, cedar waste wood crushed and classified into 3 mm to 10 mm was used. The composition of the biomass used is listed in Table 2.

[0065] [Table 2]

[0066]

[0067] The feed rate of biomass into the rotary kiln was 2.0 kg / h. The yield of the obtained biomass char was 33.9 mass %, the volatile matter concentration was 40.1 mass %, and the calorific value was 7770 kcal / kg.

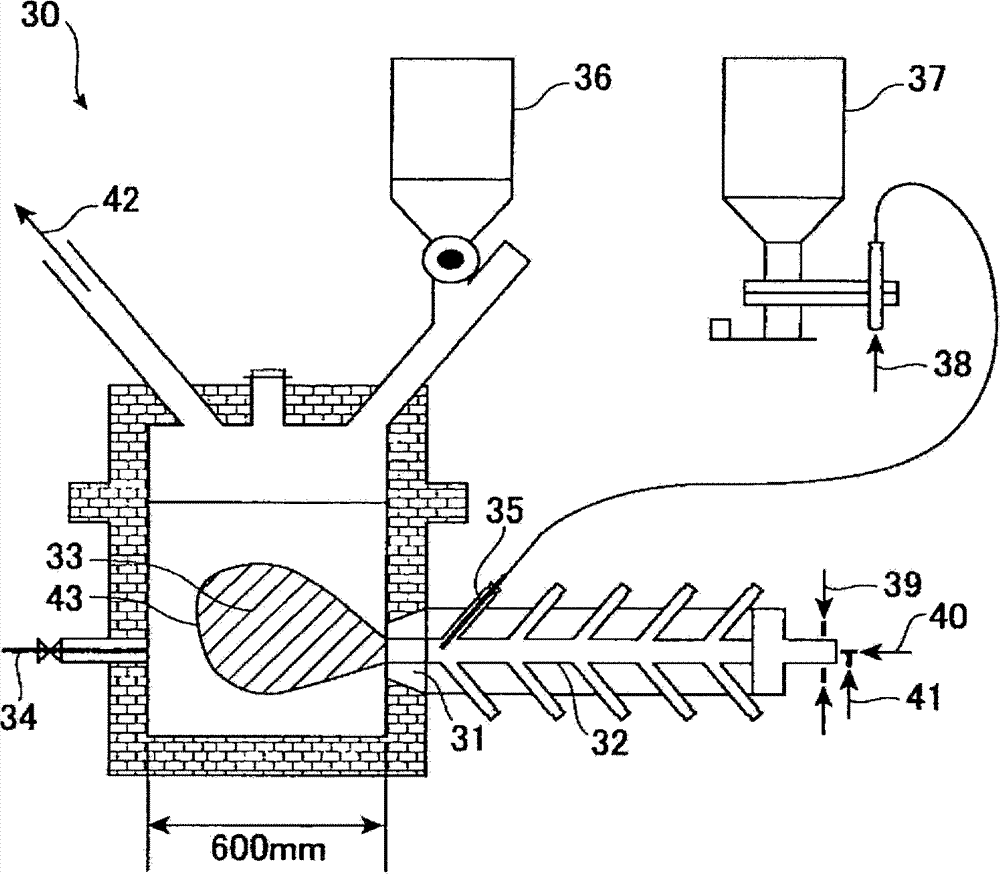

[0068] The biomass coke obtained above was pulverized, mixed with pulverized coal having the composition shown in Table 3, and evaluated for combusti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com