Low-temperature and retarding processor for drying, sterilizing and removing mold for barn

A technology of drying, sterilization and processor, applied in the direction of dryer, drying gas arrangement, drying, etc., can solve the problem of lack of large-scale processing of high-moisture grains, shorten the drying time of the warehouse, have no mildew loss, Guarantee the effect of safety and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

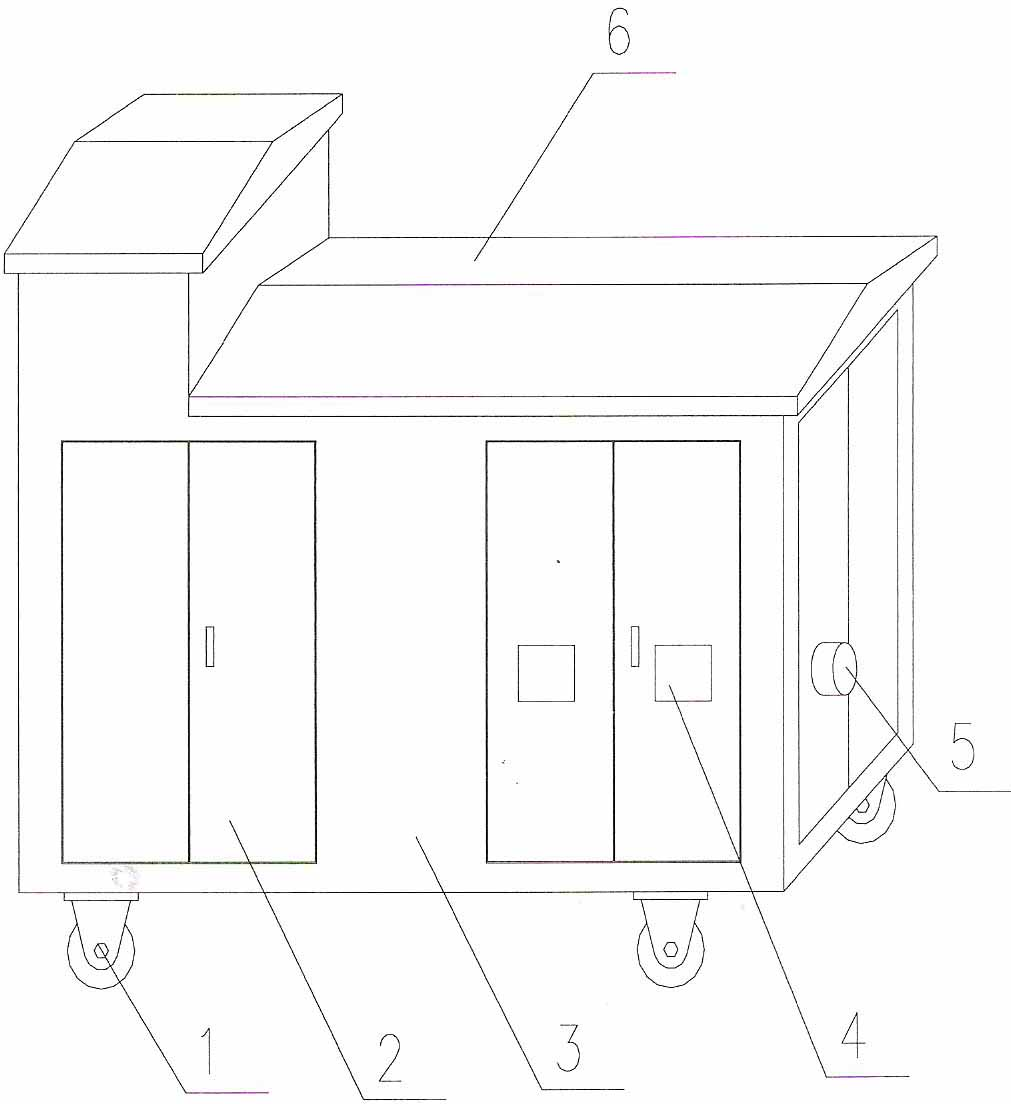

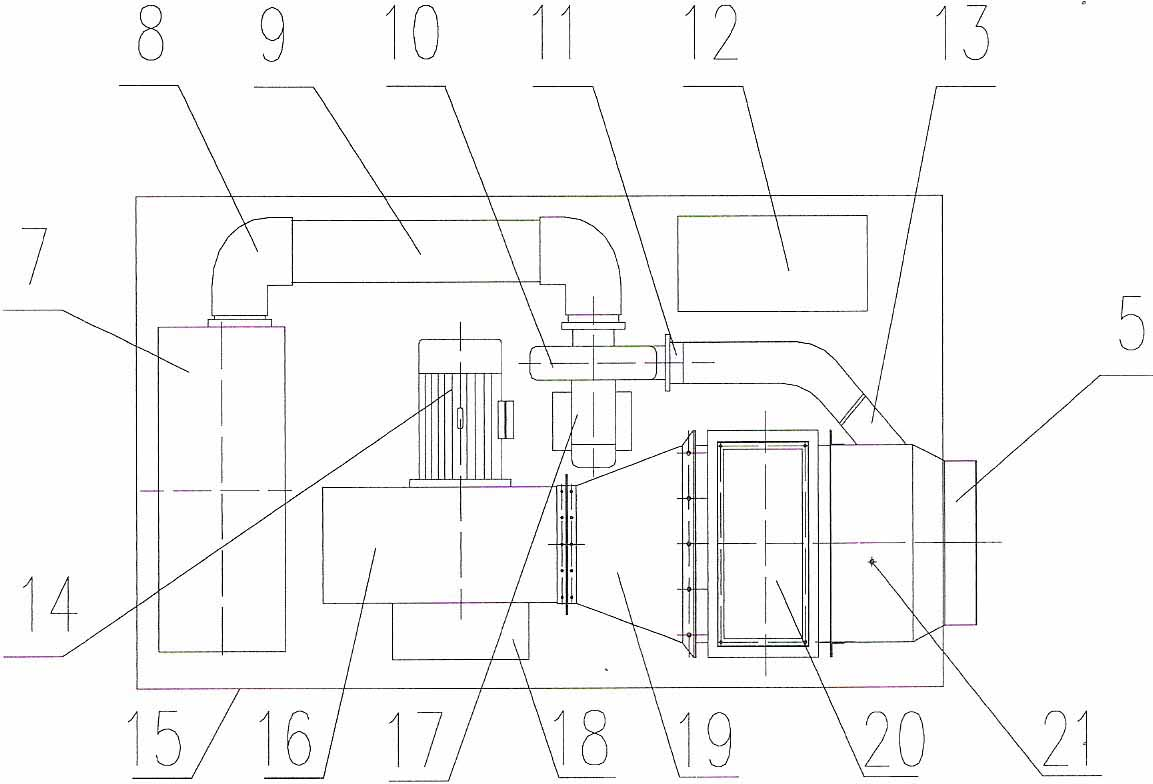

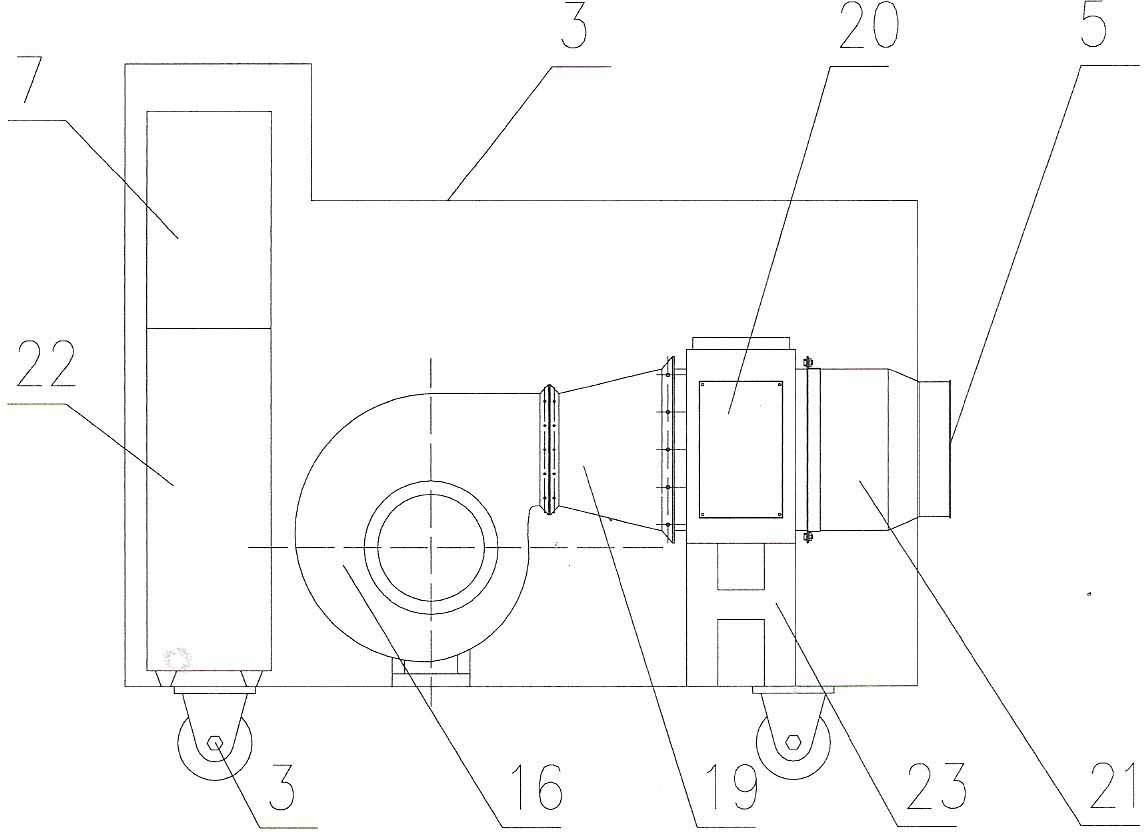

[0050] A granary low-temperature, slow-speed drying, sterilizing and mildew-removing processor, comprising a housing, in which a grain ventilator and a granary ozone processor are installed; the grain ventilator includes a granary fan 16, and the granary fan is connected to an electric heater through a soft connection 20 are connected, the square outlet of the electric heater is connected with the square variable circle tee, the circular outlet of the square variable circle tee is connected with the circular air supply outlet 5, and the circular air supply outlet is arranged on the grain pile through the main air duct 24 of the software. The main air duct above is connected, and the main air duct is connected with a plurality of horizontal branch air pipes, and the horizontal branch air pipe is connected with the vertical ventilation pipe 28 extending into the grain pile, and the lower end of the vertical ventilation pipe is connected with the stainless steel ventilation pipe th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com