Smell mixing-free multilayer steaming boiler

A steamer and steam technology, which is applied to steam cooking utensils, cooking utensils, household utensils, etc., can solve the problems affecting the flavor of dishes, etc., and achieve the effects of obvious anti-smear effect, simple structure, and avoid steam mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

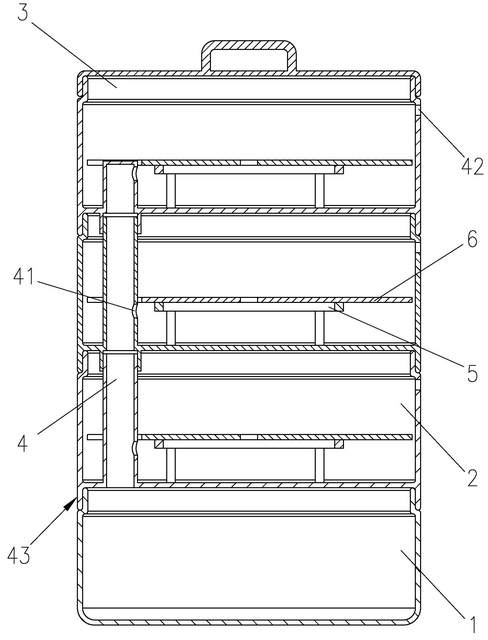

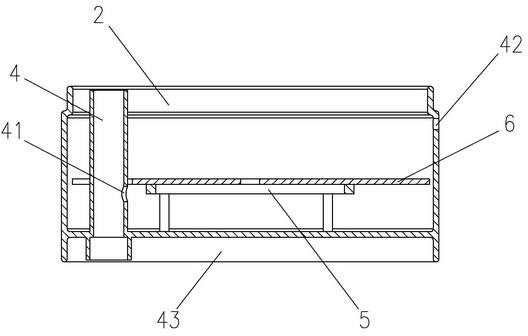

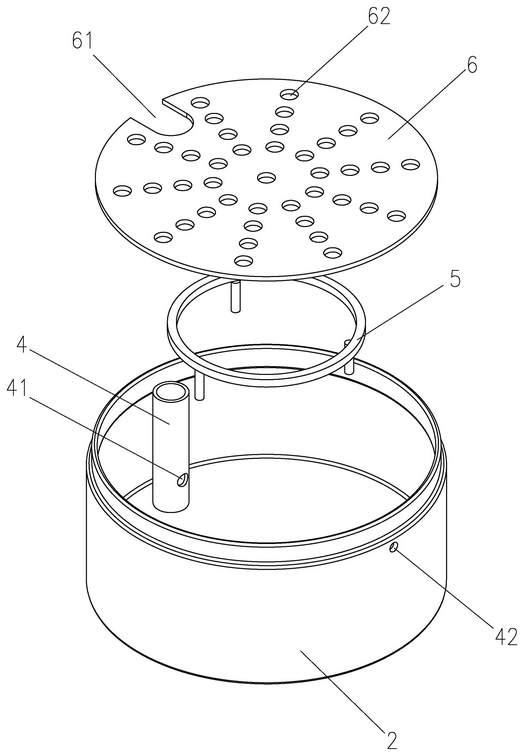

[0018] Such as figure 1 , figure 2 , image 3 As shown, a multi-layer steamer without cross-flavoring comprises: a heating pot 1, which is characterized in that: the heating pot 1 is also provided with several layers of steamers 2, and the bottom of the steamer 2 is provided with a steam sleeve 4, and the steam The casing 4 extends from the outside through the bottom of the steamer 2 to the inside of the steamer 2, and the steam casing 4 inside the steamer 2 is also provided with a steam hole 41; the steam casing 4 of the upper and lower adjacent two-layer steamer 2 nested with each other; the wall of each steamer 2 is provided with vent holes 42; the steamer 2 at the top is also provided with a pot cover 3.

[0019] Preferably, the diameter of the exhaust hole 42 is smaller than the diameter of the steam hole 41 .

[0020] Preferably, each layer of steamer 2 is provided with a bracket 5 and a steaming tray 6, and the steaming tray 6 is placed on the top of the bracket 5, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com