Automatic package removing mechanism of beverage manufacturing device

A technology of beverage preparation device and beverage bag, which is applied in beverage preparation device, home appliances, applications, etc., can solve the problems of polluting coffee beverage, affecting the taste, and not being able to drop the bag, so as to achieve the effect of ensuring reliability and simple shedding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

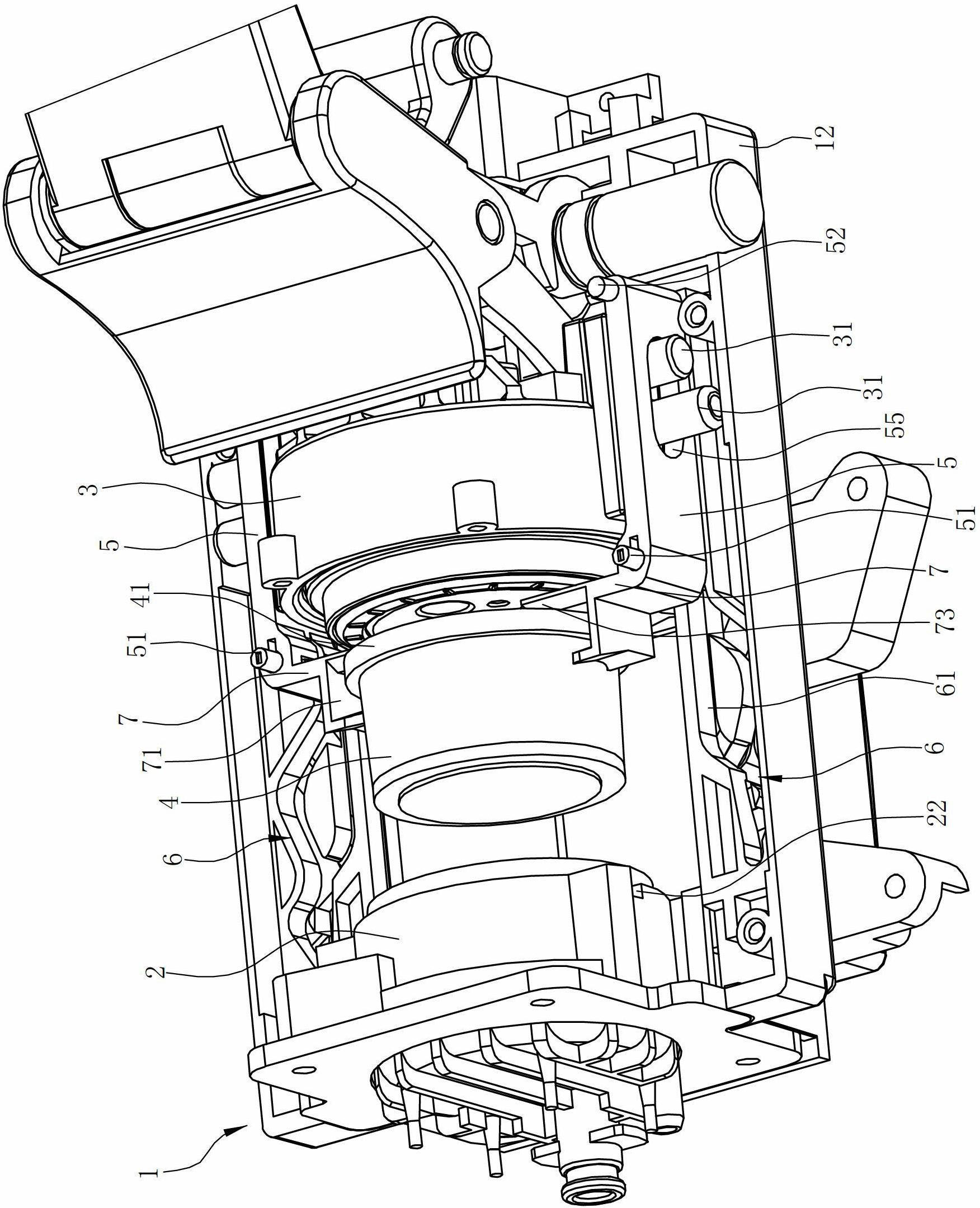

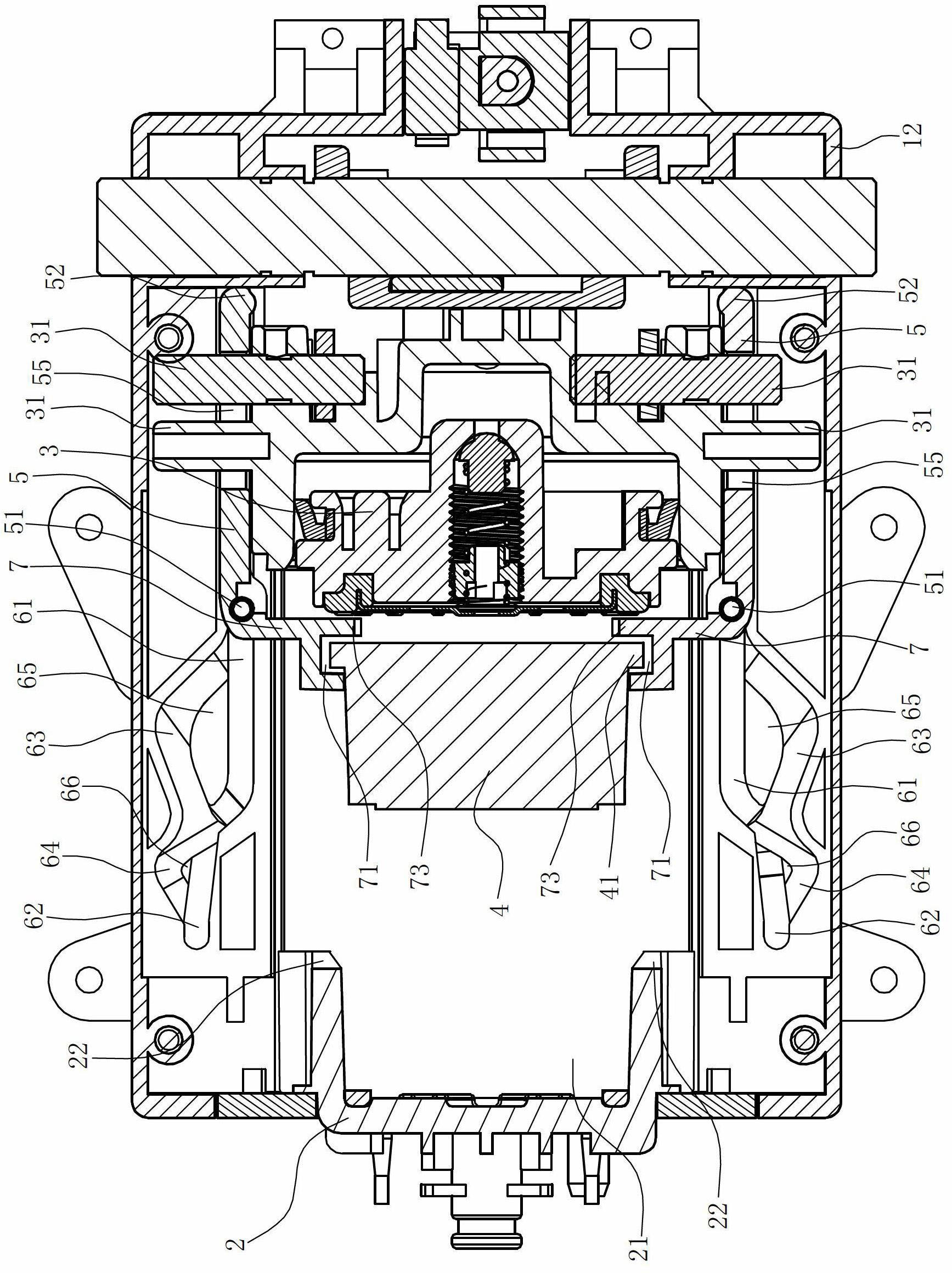

[0034] The present invention will be further described in detail below with reference to the embodiments of the accompanying drawings.

[0035] like Figure 1-16 shown, is a preferred embodiment of the present invention.

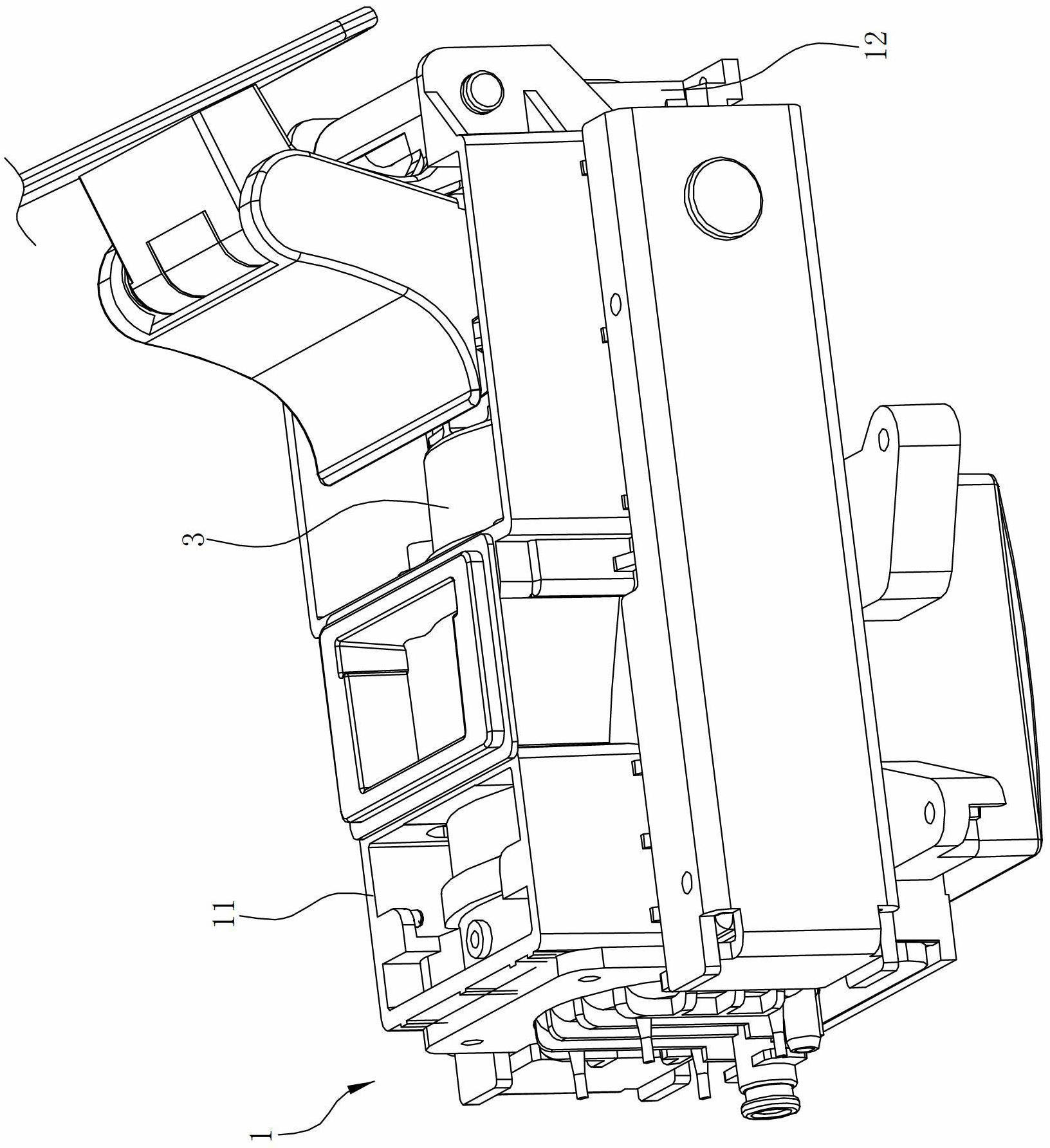

[0036] An automatic bag dropping mechanism of a beverage preparation device includes an organic base 1, the base 1 is formed by butt joint connection of an upper casing 11 and a lower casing 12, and the lower casing 12 is provided with a bag dropping opening 121.

[0037] The first machine part 2 with a liquid outlet hole is fixed on the front part of the machine base 1 , and the first machine part 2 has a accommodating cavity 21 for accommodating a beverage package 4 with an annular edge 41 .

[0038] The second machine part 3 with the water inlet hole is restrained at the rear of the machine base 1 and can slide back and forth relative to the first machine part 2 . The second part 3 is composed of a casing and a piston body inside the casing. The piston ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com