Continuous round casing forming machine for thin plate

A technology of forming machine and shell, applied in the field of machinery, can solve problems such as difficult to take out, long production cycle, low production efficiency, etc., and achieve the effects of convenient operation, reduction of production cycle, and improvement of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

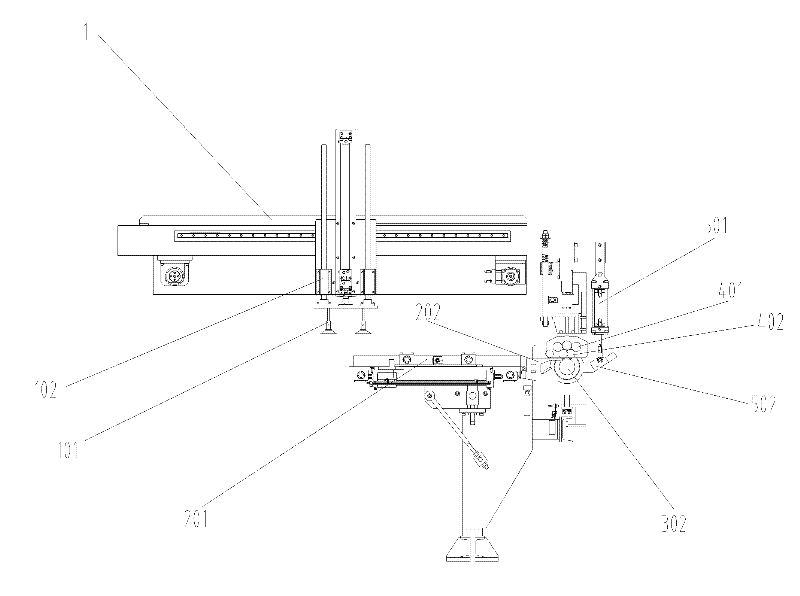

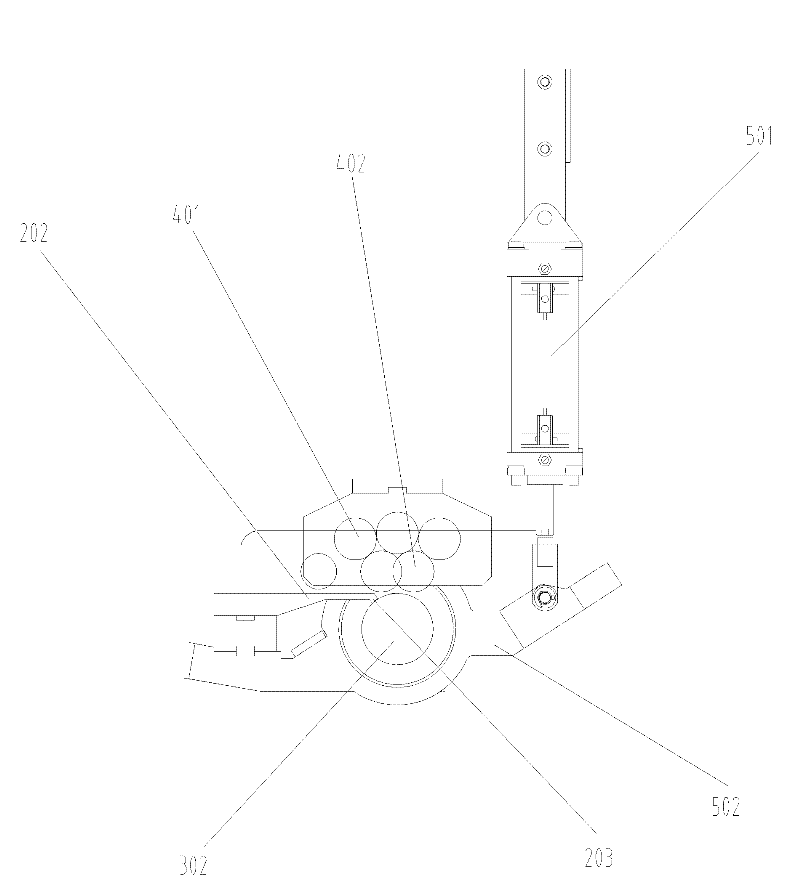

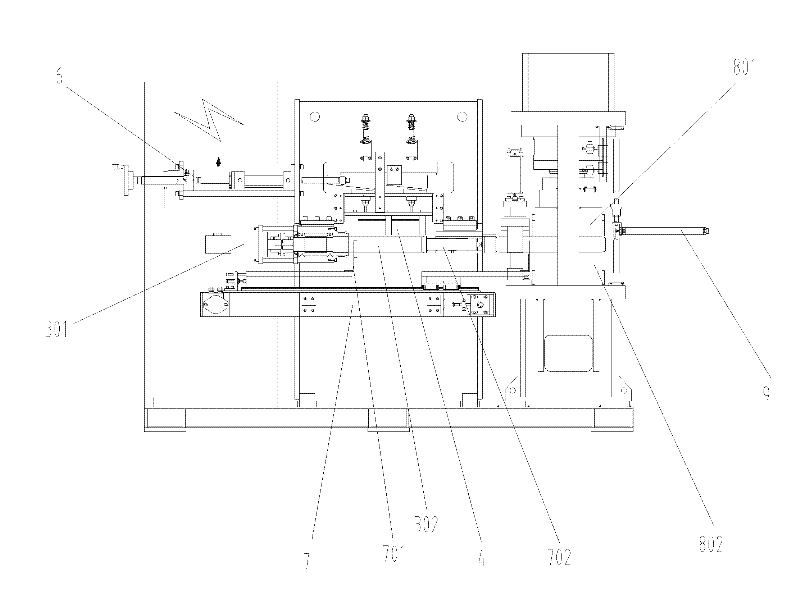

[0025] Such as Figure 1-Figure 3 As shown, the specific embodiment of the continuous thin-plate circular shell forming machine of the present invention includes a feeding device, a plate rolling device, a turning device, a pushing device, a full-circle device, and a taking-out device.

[0026] Wherein, the feeding device includes a first pushing device, a material taking device 1, a feeding platform, a clamping device, and a second pushing device. The first pushing device is composed of a cylinder and a push rod, and is used to push the multi-layer boards together to the area where the reclaiming device is convenient for retrieving. The pick-up device includes a suction cup 101 driven by a cylinder 102 and a synchronous belt driven by a reduction motor. The cylinder 102 is located on the synchronous belt and is used to put the plate on the feeding platform. The feeding platform includes a front platform 201 and a rear platform 202, the rear platform is grid-shaped, and its e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com