Concentric sleeve type multi-layer coextrusion film blowing machine head

A multi-layer co-extrusion and sleeve-type technology, which is applied in the field of film blowing equipment, can solve the problems of large difference in length of radial runners, high precision requirements of sealing interface, and large sealing interface area, so as to reduce heat consumption, Easy sealing and low sealing precision requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

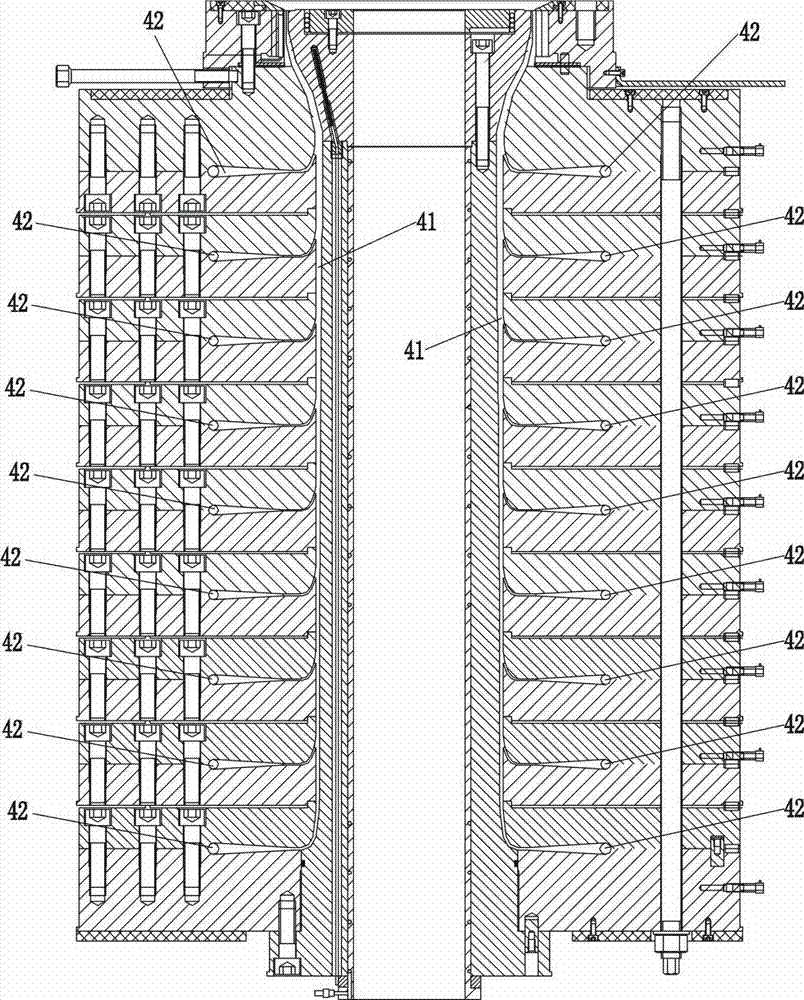

[0037] Figure 6 As shown, the concentric sleeve type multi-layer co-extrusion blown film head is provided with three-layer material flow channels.

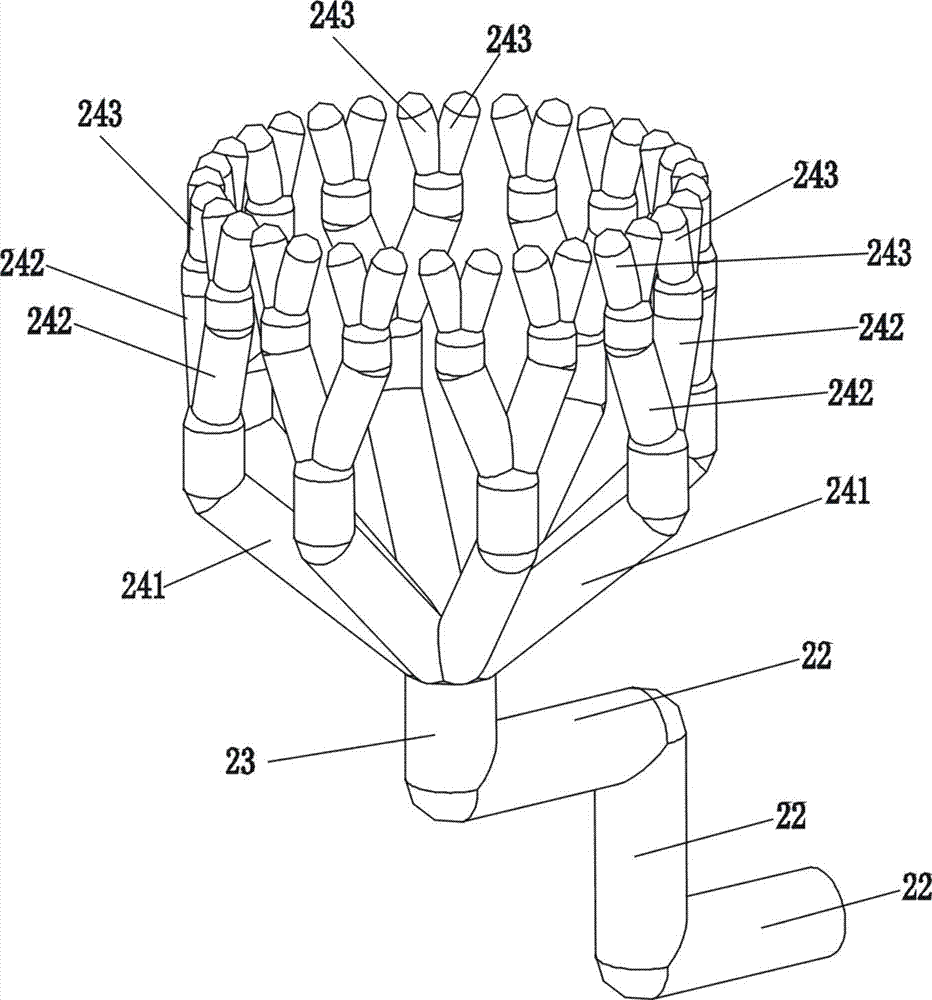

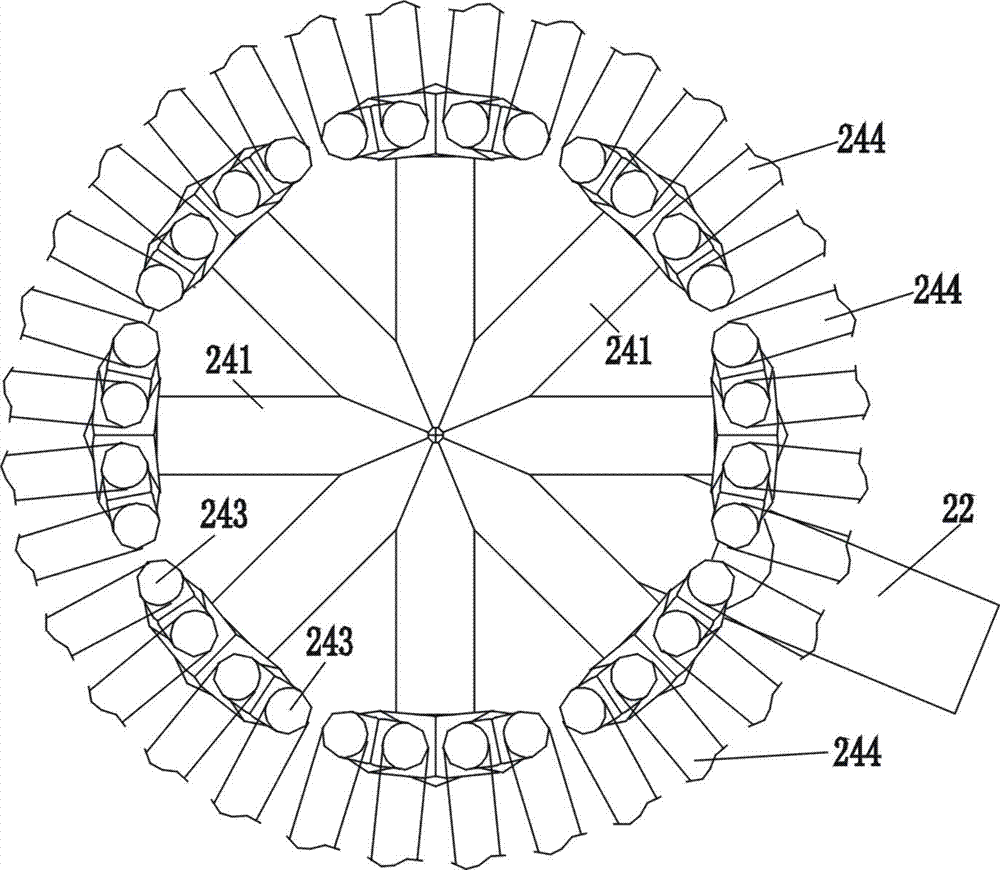

[0038] Figure 6 , Figure 7 , Figure 12 , Figure 13 As shown, the flow path of the outermost material includes a feed inlet 31, an eccentric main flow path 32, a central main flow path 33, a radial branch flow path, and thirty-two spiral flow paths 35, and the circumferential direction between each spiral flow path 35 The spacing is the same, and the stagger between every two adjacent spiral flow channels 35 is 11.25°. Wherein the feed port 31 is connected to the eccentric main channel 32, and the eccentric main channel 32 is connected to the center main channel 33, and the radial runner of the outermost layer material comprises the peripheral section 344 of the runner and the central section 341 of the runner, and the outermost material There are thirty-two peripheral sections 344 of the runners, and the peripheral secti...

Embodiment 2

[0044] In embodiment two, the number of runners is five layers, such as Figure 15 shown.

[0045]Wherein the central main channel 53 of the outermost layer material connects the eight branch channel central sections 541 of the outermost material, and the eight branch channel central sections 541 branch upwards to form sixteen branch channels, and the sixteen branch channels branch upwards to form three branches. There are twelve thin flow channels, each of which is connected to a peripheral section 544 of a branch channel, and each peripheral section 544 of a branch channel is correspondingly connected to a spiral flow channel 55 .

[0046] The central main channel 43 of the fourth layer of material is connected to the central section 441 of the eight sub-channels of the fourth layer of material, and the central section 441 of the eight sub-channels bifurcates upwards to form sixteen branch channels, and the sixteen sub-channels bifurcate upwards to form thirty There are two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com