Preparation technology for spiral steel mesh rubber belt

A preparation process, spiral steel technology, applied in the direction of belts, other household utensils, household utensils, etc., can solve the problems of single-layer belt core strength, low strength, impact resistance, curling, elongation, etc., to simplify the production process and Joint method, enhance the overall strength, increase the effect of cost performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

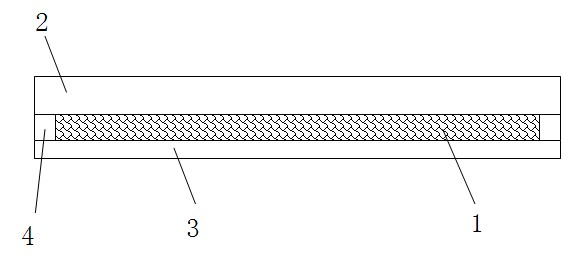

[0026] A preparation process for a spiral steel mesh rubber belt body. The prepared belt body has a width of 2800mm, a thickness of 25mm, and a length of 20mm. The skeleton material is a spiral steel mesh with a thickness of 6mm, and the covering rubber is EPDM rubber. EPDM.

[0027] The preparation process is as follows:

[0028] 1. Cover rubber calendering

[0029] Roll the upper cover rubber 2 and the lower cover rubber 3 so that the thickness of the upper and lower cover rubbers is 14-16mm;

[0030] Among them, the upper cover rubber and the lower cover rubber are mainly made of EPDM rubber mixed with other rubber materials;

[0031] 2. Spiral steel mesh calendering

[0032] The core rubber is respectively rolled on the upper and lower surfaces of the spiral steel mesh 1, and the thickness of the core rubber after rolling is 8mm;

[0033] The core rubber is formed by mixing natural rubber and neoprene;

[0034] 3. Forming

[0035] Lay the rolled spiral steel mesh wi...

Embodiment 2

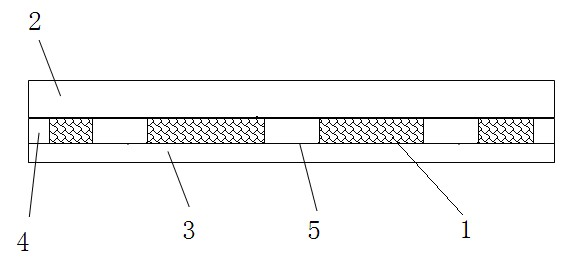

[0042] The difference between this embodiment and Example 1 is that in order to further increase the width of the single-block spiral steel mesh rubber belt body, in Example 1, in order to further increase the width of the single-block spiral steel mesh rubber belt body, the step 3 ) during molding, a widening part 5 equal to the thickness of the spiral steel mesh is arranged on one side of the width direction of the spiral steel mesh. Set up a spiral steel mesh with core glue of equal thickness, and finally lay the upper covering glue. The width of the upper and lower covering glue = the width of the two spiral steel mesh + the width of the widening part + the width of the side glue; the widening part It is made of any one of rubber material, polyester cloth, and cotton canvas core.

[0043] After a lot of research time, it has been proved that the strength of the belt body prepared by using polyester or cotton canvas core as the skeleton layer can only reach 200-300N / mm, whi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com