Printing template and flat-panel printer

A flatbed printer, printer technology, applied in typewriters, printing devices, printing and other directions, can solve the problems of wear of the rotating spindle, affecting the printing quality, affecting the feeding accuracy of the printing template, etc., to reduce wear, improve printing quality, and improve feed. The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

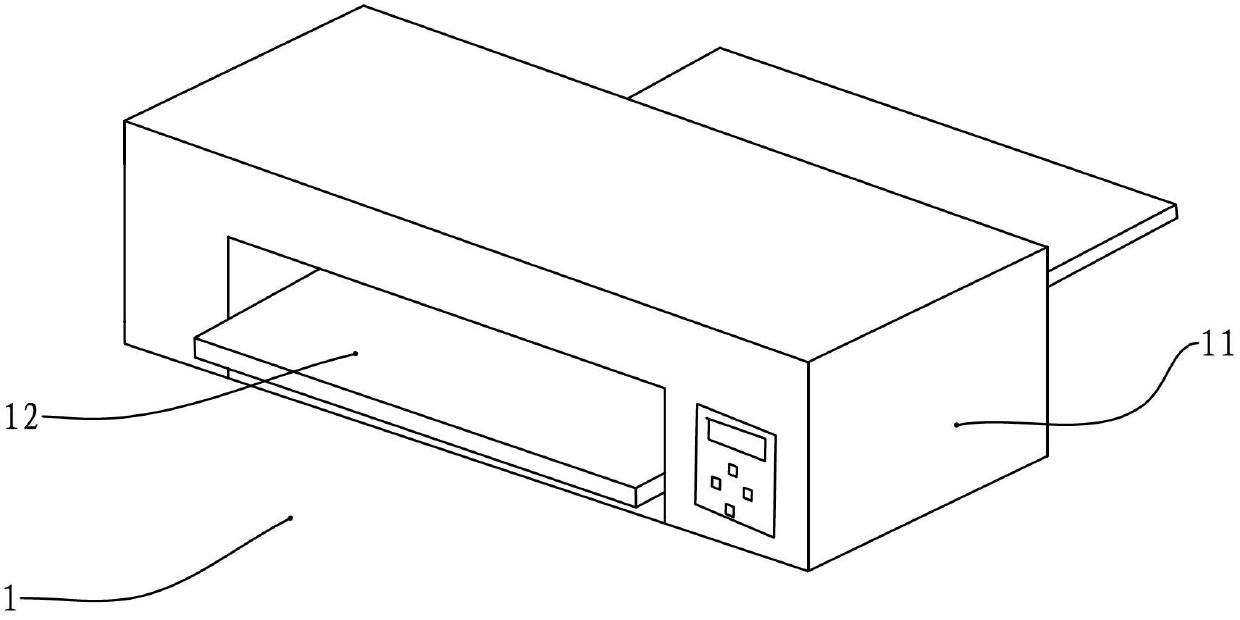

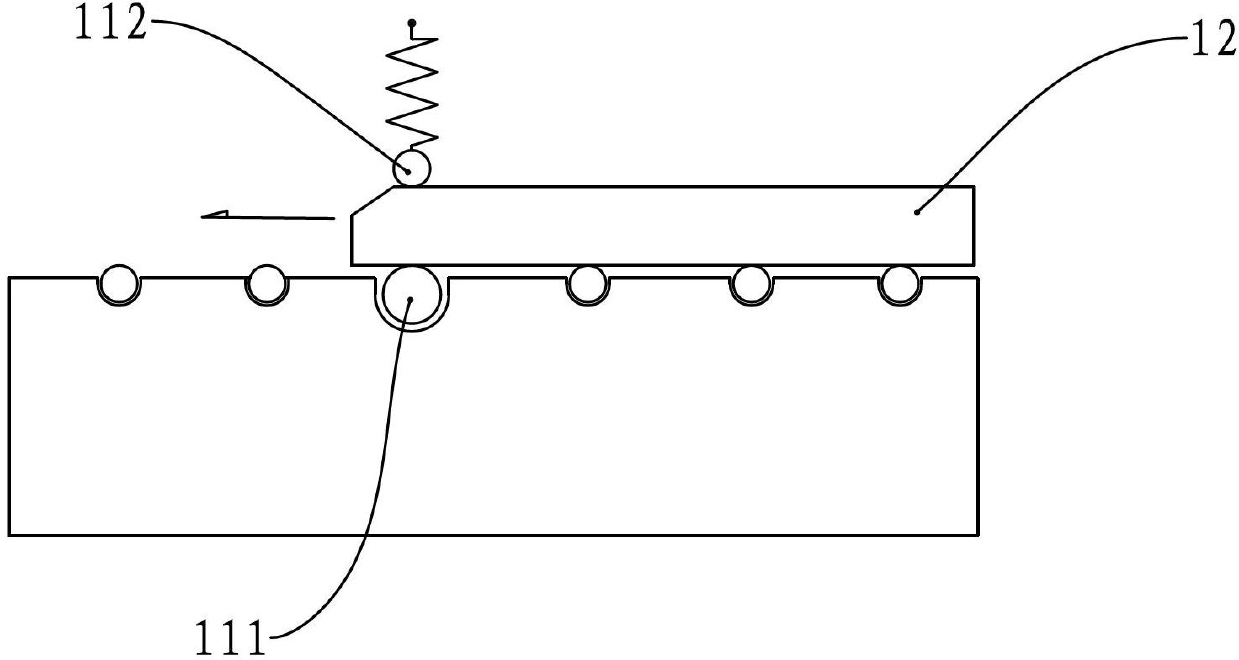

[0016] see figure 1 , the flatbed printer 1 includes a printer body 11 and a printing template 12 . The main body of the printer is also equipped with a printing inkjet system, a drive system and a circuit control system ( figure 1 are not shown). The printing template 12 is movably installed on the printer main body 11 and can be linearly fed relative to the printer main body 11 .

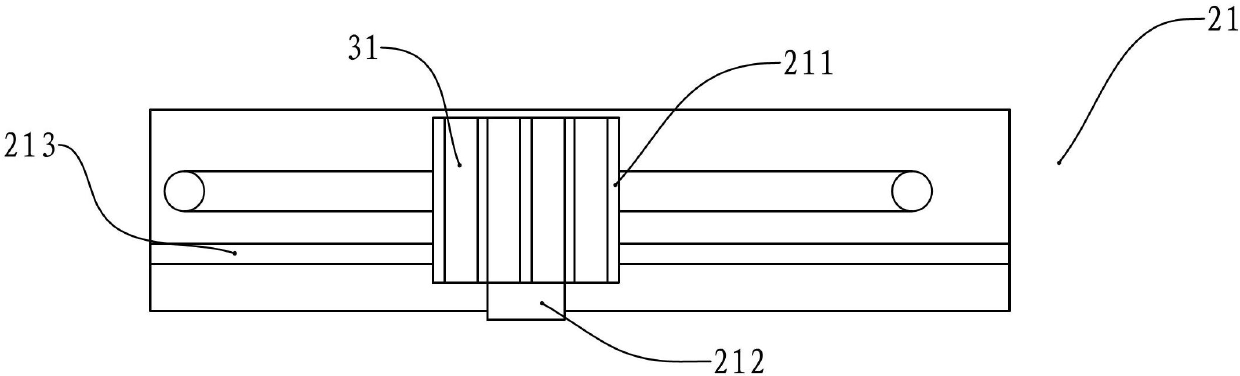

[0017] see figure 2 , the printing inkjet system 21 is arranged in the flatbed printer, which includes a printing carriage 211 , and a printing nozzle 212 is arranged at the bottom of the printing carriage 211 . The printing carriage 211 reciprocates left and right along the guide rail 213 during the printing process. The ink cartridge 31 is installed in the printing carriage 211 , the ink cartridge 31 contains ink, and the ink cartridge 31 is fluidly connected with t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap