Railway transportation truck special for coiled steel and powdery goods

A technology of railway transportation and steel coiling, which is applied in the direction of transporting passenger cars, railway car body parts, freight cars, etc., which can solve the problems of time-consuming and laborious, low vehicle utilization rate, and increased transportation costs, so as to improve use efficiency, reduce transportation costs, The effect of reducing labor intensity and labor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

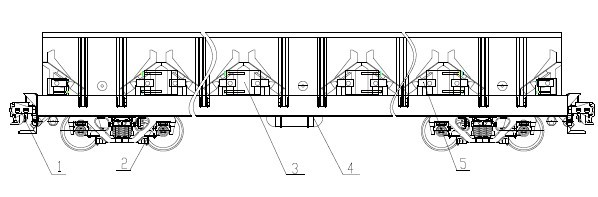

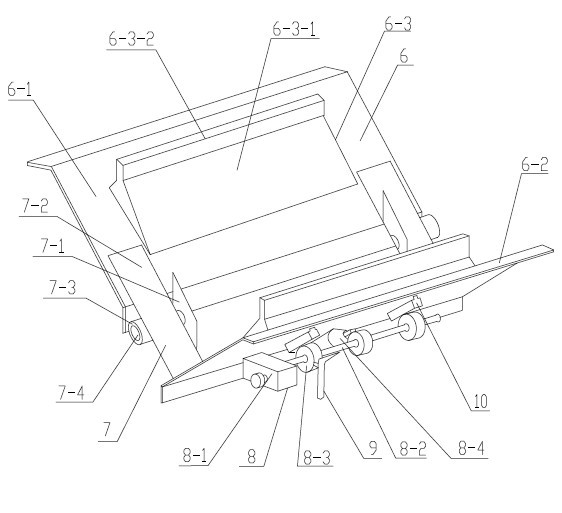

[0016] Embodiment one: if figure 1 As shown, a coiled steel-powder cargo railway transport special freight car, including a coupler buffer device 1, a bogie 2, an open car body 3 and a braking device 4, is characterized in that the bottom frame along the open car body 3 The longitudinal direction is fixedly connected with a transverse coil steel fixing unit 5. The gondola car body is mainly composed of three parts: underframe, side wall and end wall. The main section steel and plates are Q450NQR1 high-strength fire-resistant steel approved by the document No. [2003] No. 387. The coupler buffer device adopts E-grade steel No. 17 coupler and forged coupler frame to improve the safety and reliability of the coupler buffer device; the Zhuan K6 bogie is used to ensure that the running speed of the vehicle can reach 120km / h, which meets the speed increase requirements and improves the operation of the vehicle Quality, reducing wheel and rail wear. In addition to using the horizont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com